Breaking barriers and forging paths of innovation are just a few of the qualities engineers are known for embodying. In the realm of steel, circuits, and software—where creativity meets precision—engineers are often described as trailblazers, reinventing the world to make life easier and fairer for those around them.

For Devin Hamilton, the desire to be a trailblazer and make the world a better place is personal.

Hamilton is a mechanical engineer working to make the world more accessible for people with disabilities, building custom solutions through his company, RapAdapt, that are tailored to each client’s individual needs. Hamilton deeply understands some of the limitations people with disabilities face every day because, since early childhood, Hamilton has had cerebral palsy.

Cerebral palsy, commonly called CP, is a group of disorders that affect a person’s body movement and muscle coordination. Often, cerebral palsy affects the communication between the brain and muscles, making it difficult to control one’s body.

For Hamilton, cerebral palsy has allowed him to see the world differently. This unique perspective has both given Hamilton a deep understanding of the challenges that people with disabilities face on a daily basis, as well as the ability to look at a problem from many different angles.

“I often joke with friends that my life is one big problem,” Hamilton said. “Having CP and being an engineer has made me a monster problem solver.”

Being a monster problem solver is one of the hallmarks of a great engineer. Hamilton takes this one step further by working to impart some of his problem-solving abilities onto everyone he interacts with.

“I believe that everyone should have the ability to be a part of any community in the way that they want,” Hamilton said. “People with disabilities should be a part of figuring out how to solve any problems they may be facing because most of the time nobody understands the problem as well as they do.”

From farmer to engineer

Growing up on his family’s farm in Delhi, New York, Hamilton was no stranger to adaptive tools and technology. With his parents, Hamilton built tools to make his work on the farm more accessible and safer. Together, they built solutions like an attachable plow and a hitch for his wheelchair to carry tools and equipment around the farm and adjustable handles for machinery like tractors and skid-steers. When things broke, or if Hamilton wanted to try something new, he and his parents would design and build a solution to tackle almost any chore or job he wanted to try.

“We tended to do a lot of things ourselves,” Hamilton explained. “The farm was a catalyst for a lot of what I do now—just a lot of problem-solving, doing things the right way, and saving time.”

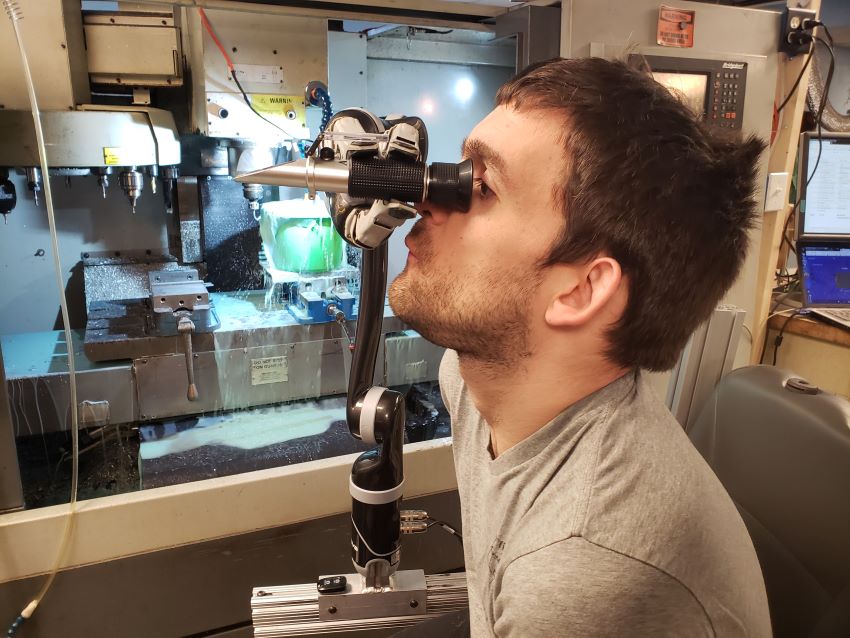

To take his engineering skills a step further, in 2007, Hamilton taught himself how to use SOLIDWORKS, a computer-aided design and engineering application. With SOLIDWORKS, Hamilton could digitally design and create almost anything and everything that could help him work on the farm and beyond. From the beginning, Hamilton’s use of SOLIDWORKS was anything but typical. When Hamilton began using SOLIDWORKS, he used a standard computer mouse with his elbow. Over the years, his workstation has evolved into a highly specialized mobile CAD station.

Today, Hamilton is a Certified SOLIDWORKS Professional (CSWP). Hamilton can model with impressive efficiency using a myriad of adaptive tools, including eye tracking, voice control, an inclined keyboard, and custom hotkey scripts and macros, thanks to his training, education, and passion for engineering.

“Achieving my current level of proficiency with SOLIDWORKS has definitely been a journey,” Hamilton said. “The pressures of a life in agriculture and engineering have taught me the importance of efficiency. Using SOLIDWORKS with a disability such as cerebral palsy has forced me to continually merge assistive technology with engineering to take computer access to the next level.”

The creation of RapAdapt

Inspired by the adaptations he made and designed for himself, Hamilton started his own company in 2016. At RapAdapt, Hamilton combines assistive technology with engineering consultations to help design and produce one-off, custom solutions that are tailor-made for individuals with disabilities. Hamilton and his team at RapAdapt will visit their clients, assess their needs, and create the best solution.

As Hamilton explained, the “Rap” in RapAdapt stands for rapid.

While it can typically be a long and arduous process of financing the technology, receiving it, scheduling evaluations with therapists, and finally tweaking it to fit the individual’s needs, Hamilton can cut the typical wait time of two to six months in half because he offers an end-to-end solution. Additionally, because RapAdapt solutions are customized and often designed with the customer, there typically is very little rework needed.

Hamilton does everything from designing custom modifications to make wheelchairs more beach accessible to creating personalized cutlery that is easy to hold and helping people access the computer who can’t use traditional modifications. His goal is to ensure others have equal access and the ability to use things many take for granted daily.

On every project, Hamilton draws upon his experiences remembering his evolution in his engineering world.

“Just as I am always looking for a more efficient way to do things for myself, I am always looking for ways to make things more efficient for everyone I work with,” Hamilton said. “If I’m working with someone that might take an hour to complete a task and is fine with that but has ten other things to do, I try to push the ‘good enough envelope’ by looking at that 1-hour task and asking, ‘can we make this easier and faster?’ for them.”

Hamilton and his team at RapAdapt also consult with businesses to help them meet the accessibility needs of their employees.

“One of my biggest motivating factors is being able to help people to become more able to do what they want to do, whatever it may be,” Hamilton said. “Helping others helps me overcome anything too.”

Teamwork makes the dream work

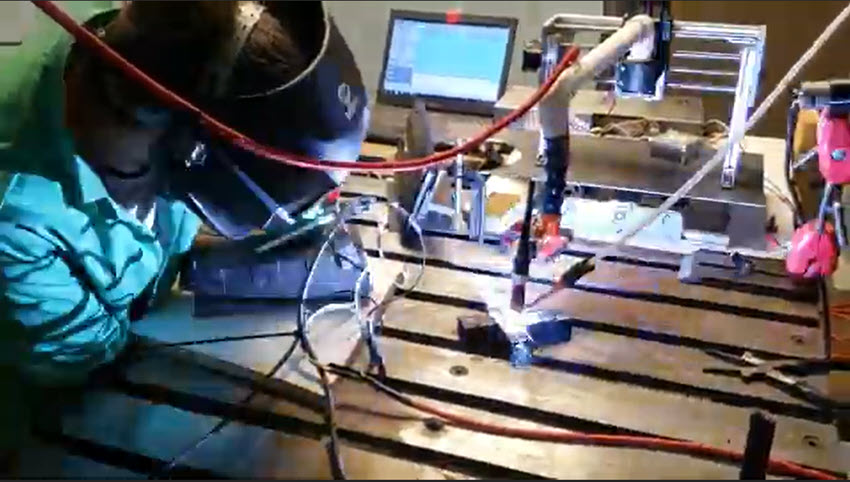

For Hamilton, designing adaptive equipment with CAD is not enough, he often builds what he designs. The RapAdapt machine shop is full of small adaptations that allow Hamilton to make his designs a reality. Despite all the modifications, Hamilton still requires some assistance with physical tasks. Hamilton does not work alone and has a team of visionaries, friends, and professionals that help him bring RapAdapt to life.

“I literally grew up on the shop floor working with my parents on the farm,” Hamilton said. “Physically building and manufacturing is in my blood. I’m fortunate enough to be surrounded by a team that allows me to have a physical hand in every step of the process.”

Design for accessibility

Hamilton has dedicated his career and life to design for accessibility. Still, he will be the first to tell you that designing for accessibility should not start and certainly not stop with engineering.

“The question is, ‘where does accessibility really begin?’” Hamilton asks. “Accessibility doesn’t always begin on a drawing board or in SOLIDWORKS. In fact, most of the time, it begins in or with an inclusive mindset.”

Hamilton considers making the world more equitable to be a win-win for everyone, not just those with disabilities, because if something is more accessible for a disabled individual, it is also more accessible for someone who is abled-bodied too.

Hamilton wants to see engineers and designers integrate the thoughts, opinions, and needs of the disabled population into their work.

“The fastest way to supercharge innovation and change the world is to make sure everyone has a seat at the table both literally and metaphorically.”

For Hamilton, designing for accessibility isn’t enough. He believes we must push the envelope on what we understand equality to be for people with disabilities.

“We are all humans,” Hamilton said. “Some humans bring a little something extra to the table called a disability. We should all strive to incorporate every human in the human experience.”

Devin Hamilton isn’t the only one making an impact in engineering. Check out some of the other humans driving progress.