Sailing boats have been used for centuries to transport goods and people across the sea. Today, they’re something we tend to associate with small recreational boats and yachts as opposed to commercial shipping. However, a new wave of technology developments around wind assisted ship propulsion (WASP) – also known as wind assisted propulsion systems (WAPS) – means that in the not-too-distant future, sails might become commonplace on everything from cargo ships and tankers to ferries and cruise ships.

Steering the return to wind power is the industry’s imperative to become more sustainable. Responsible for around 90% of global trade, international shipping may be the most carbon efficient way of transporting cargo, but it’s still highly polluting. It’s estimated that there are over 50,000 merchant ships in service, transporting raw materials, food and manufactured goods around the world and burning 300 million tons of fossil fuels every year in the process.

The International Maritime Organization (IMO) has set a target for international shipping to reduce total greenhouse emissions by 40% by 2030 (compared to 2008 levels), and phase them out altogether by around 2050. To meet these targets, ship owners and ship builders are focused on reducing the amount of fuel their vessels burn and evaluating all manner of alternative fuels and propulsion systems, including wind power.

What is wind assisted propulsion and what are the advantages?

Making the switch from diesel to alternative fuels such as LNG, methanol, ammonia and hydrogen is widely considered the most effective way for ship operators to reduce their carbon impact. Yet the high cost and limited availability/access to these alternative fuels means that, for now, widespread adoption is still some way off.

In the meantime, ship operators must seek complementary solutions that can be used alongside existing engines running on heavy fuel oil and, eventually, green fuels to become more sustainable. WASP is one such solution.

According to maritime classification organization DNV, WASP technologies harness the power of wind to supplement the propulsion of a vessel by generation of aerodynamic forces. Aside from the fact that wind is a readily available, completely free and renewable energy source, it also offers a number of benefits including:

- Enhanced fuel efficiency: WAPS is already proven to deliver fuel savings ranging from 5 to 9%. It could save up to 25% if installed as a retrofit and be even higher if installed on newbuilds designed to carry these sail systems.

- Ideal for retrofit: Vessel owners can choose from a variety of retrofitting options, many of which are designed to be easy to install.

- Easy to operate: Modern sails are equipped with state-of-the-art control and automation systems so they can be operated safely and without the need for extra crew.

“Numerous wind-assisted propulsion solutions are under development, many incorporating automation and smart route optimization features that hold the potential to enhance fuel efficiency, leading to reduced fuel consumption and greenhouse gas emissions.” – International Chamber of Shipping

How does wind assisted ship propulsion work?

Several innovative sailing concepts are in development today, harnessing the latest advances in aerodynamics, science and digital technology to make wind propulsion an effective and viable option for commercial shipping.

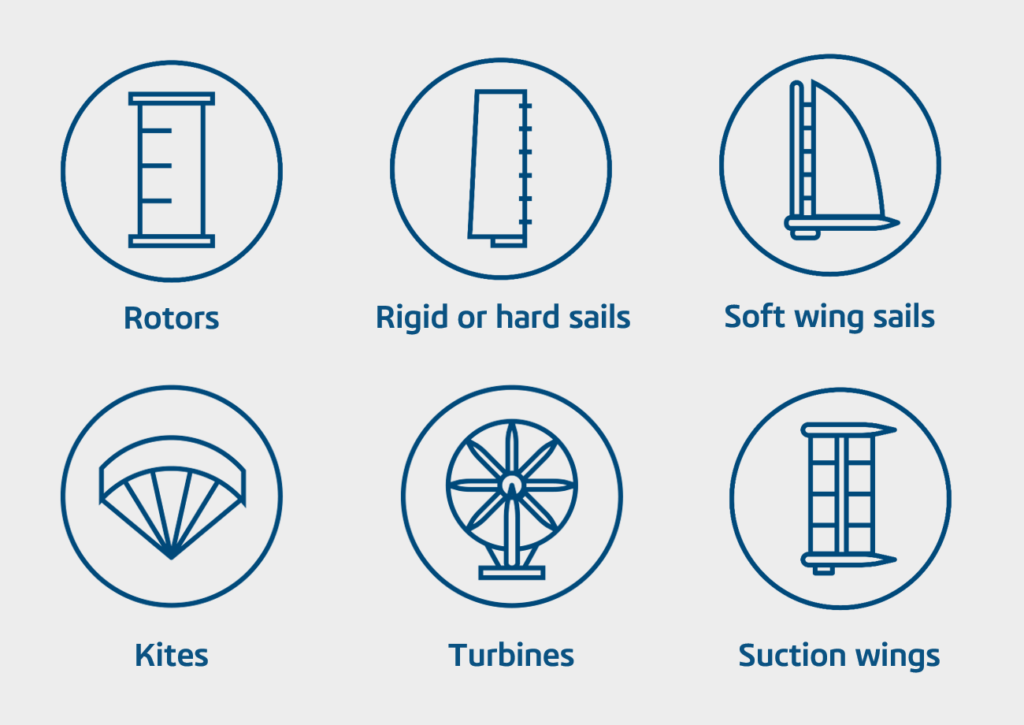

IMO splits wind propulsion into seven main categories:

- Rotors: Powered by small motors, rotors, also called Flettner sails, spin on deck. Wind blows across them to create an air pressure difference that generates lift/thrust

- Rigid or hard sails: These are made from rigid materials but there are many different systems, including foils and sails with flaps, which can retract

- Soft wing sails: This is a more traditional type of sail but there are now many variations using new, robust materials and automated control systems

- Suction wings: These fixed wings have vents and an internal fan to create suction

- Kites: Tethered to the bow, kites are deployed above the vessel to generate additional thrust at sea

- Turbines: Available in both horizontal and vertical configurations, wind turbines can be used to generate both thrust and onboard electricity

- Hull forms: The hull is designed in such a way so it functions like a large sail underneath the vessel, capturing wind to generate thrust.

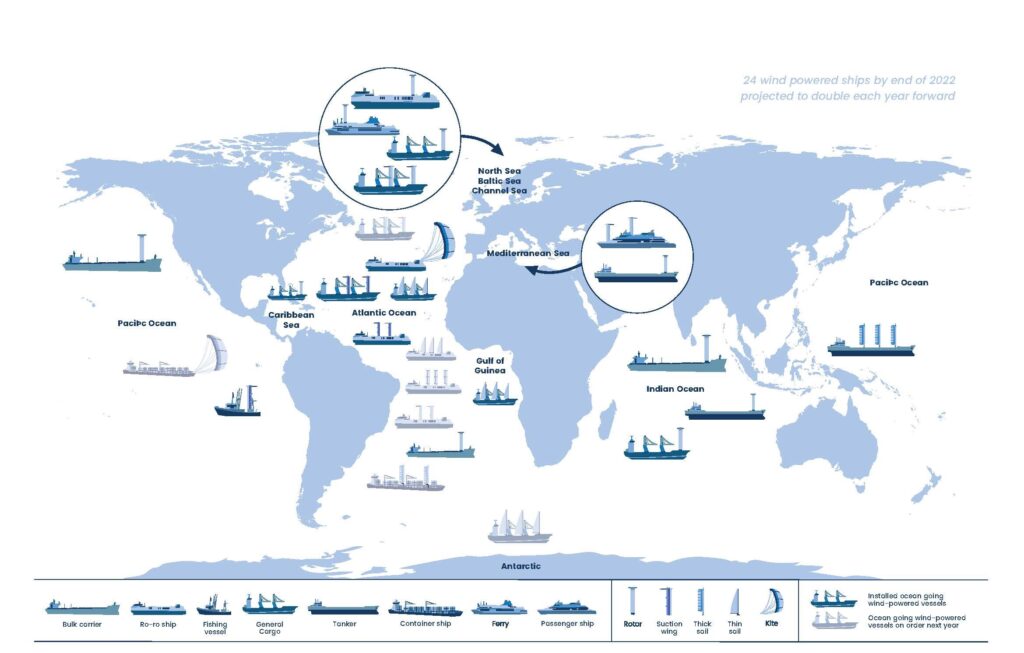

Certain systems and technologies are suited to some ships, routes and cruise speeds better than others. Smaller ships tend to be more flexible and therefore open to a wider range of options. Ro-ro, ro-pax and pax ships are good candidates as they are generally lightweight, have open deck space to mount WAPS, and don’t travel at high speeds. Larger vessels have more restrictions. Container ships, for example, must be accessible by cranes in port for loading and offloading so will need retractable rather than fixed sails. They also have limited space on deck.

Making WASP a feasible reality

The sustainable ship of the future is likely to combine all manner of technologies, from WASP systems and alternative green fuels to onboard solar panels and intelligent automated systems to optimize performance.

A new wave of exciting developers from the maritime, technology and yacht racing sectors are all working fast to launch innovative solutions, harnessing the latest virtual modelling and simulation capabilities and advanced composite materials to make wind propulsion as efficient as possible.

Chantiers de l’Atlantique in France, for instance, has developed Solid Sail, a rigid, foldable sail made of composite rectangles that goes far beyond the usual size limitations of standard fabric sails.

The company plans to install two 76-meter masts on a cargo ship, achieving a total sail area of 3000 meters-squared. Chantiers de l’Atlantique said the installation will make a meaningful contribution to the energy transition in maritime transport.

As pressure intensifies for the industry to significantly reduce its carbon emissions, others are following suit. In 2021, there were less than 15 large vessels using WAPS. By the end of 2023, more than 40 vessels will be equipped with WAPS, and growing.

“You basically can’t go wrong with wind – it’s free, it’s zero-carbon, and there are any number of retrofitting options available today with many of them quite easy to install,” said Hasso Hoffmeister, DNV sailing expert and senior principal engineer. “What is more, wind will always be available in suitable regions at no cost – it gives you a certain planning reliability and independence from the supply and price fluctuations of combustible fuels.”

Read more articles

Green corridors: from concept to reality