Design robust electronics with simulation

Awareness of sustainability and electronic waste issues in the high-tech industry is greater than ever. As well as increasing pressure from consumers and ESG investors for more sustainable products, lawmakers around the world are bringing in regulations that require manufacturers to make devices that are robust and long-lasting. At the 2022 IFA consumer electronics show, the European Commission unveiled plans for new eco-design and efficiency labeling regulations for smartphones and tablets. These are expected to pass next year and come into effect in 2024, and would represent one of the biggest steps forward for sustainability in the mobile device sector.[1]

For consumers, the most noticeable change will be an update to the familiar energy efficiency label. This will now include information about battery capacity and endurance, drop resistance, water/dust resistance and ease of repair. With this information now visible to the consumer, products that score well in these categories will have an advantage on the market. Designing to optimize for robustness and reparability will become increasingly important.

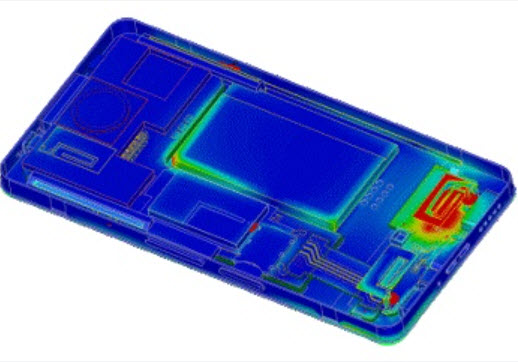

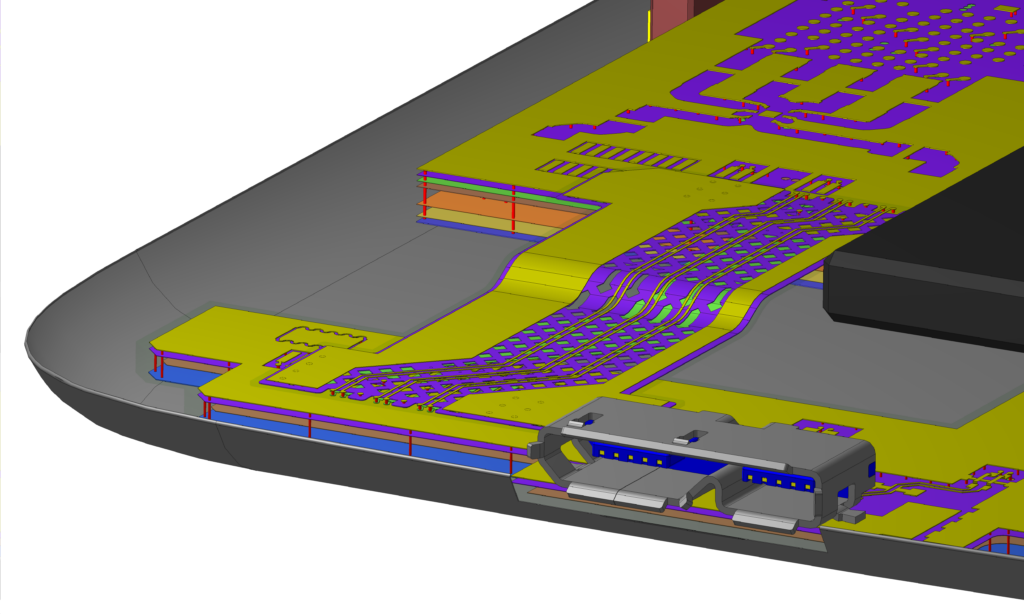

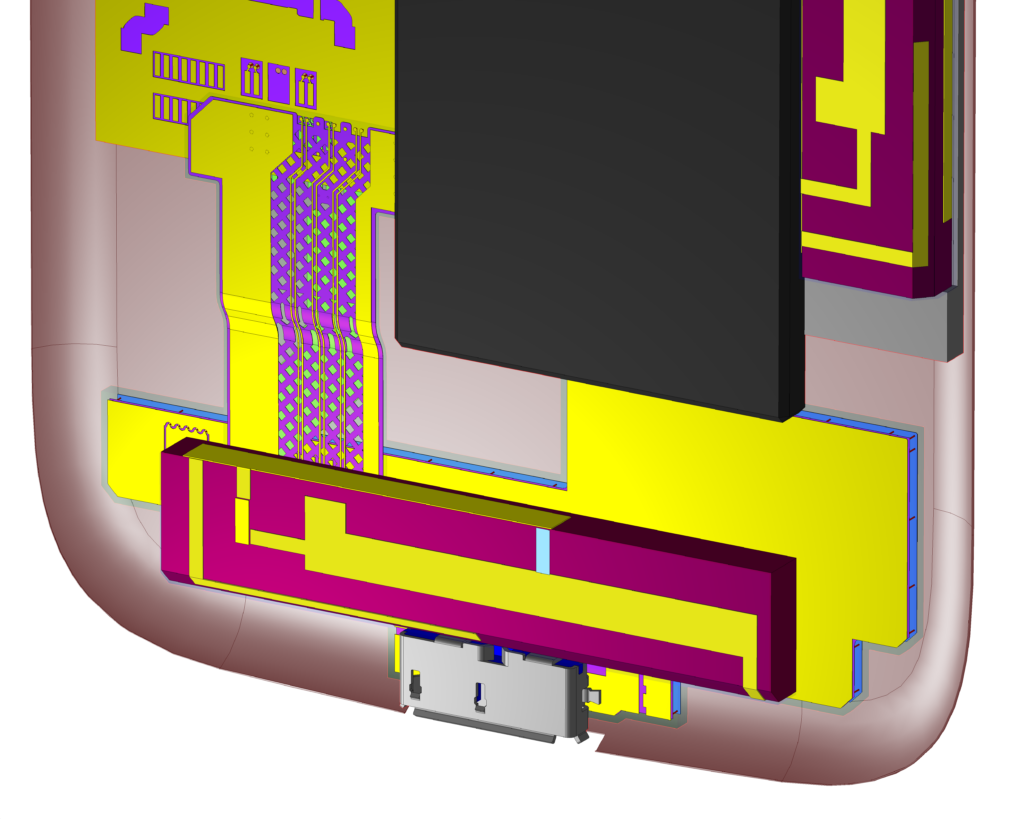

Simulation allows designers to model the durability of devices without needing physical prototypes. By using a “Virtual Twin” of the design to replicate physical tests and real world scenarios, companies can accelerate development and reduce costs, while increasing confidence that a design will meet or exceed eco-design targets.

Free fall/drop

It is inevitable that a handheld device will be dropped many times over its lifespan. Many of us have had phone screens shatter – or even the device stop working entirely – after a drop. The draft eco-design regulation would grade smartphones and tablets from A to E, depending on how many falls they withstand – an A-rated smartphone still functions after over 300 drops from a height of one meter, and an E-rated one fewer than 50.[2]

Drop testing a phone prototype in the lab is both time-consuming and expensive, requiring numerous working prototypes to be dropped, potentially until destruction. Structural simulation with SIMULIA Abaqus automates the cycle of drops and allows the effect of design modifications to be assessed rapidly, without the need to build an entirely new prototype. By visualizing the stresses inside the device assembly, engineers can identify likely failure sites. Targeted reinforcement can increase robustness while keeping the device lightweight.

Water ingress protection

Water and dust can damage delicate electronics. The draft eco-design regulations grade devices by how effectively they prevent the ingress of contaminants. For water, the proposed levels of protection range from “splashing” through “jetting”, “powerful jetting”, “temporary immersion, 1 meter depth” to “continuous immersion, 1 meter or more”.[2]

Smartphones typically include seals around buttons, speakers and connectors. However, water pressure can shift or deform the seal enough for liquid to leak into the device. Seals can be simulated in Abaqus under various water pressure conditions to ensure they hold up to damage.

Battery endurance

Every time a battery is charged and discharged, ions flow and chemical processes occur within the cell. Over time, the battery chemistry starts to degrade and its capacity is reduced. The device begins to run out of charge faster and faster until it becomes impractical to use. The draft eco-design regulations score devices both by how long the battery lasts on a full charge under set load conditions, and how many charging cycles the battery can endure before dropping to 80% of its original capacity.[2]

Dassault Systèmes offers an in-depth battery simulation workflow that covers the many different aspects of battery design including chemistry, swelling, thermal performance and structural integrity. For more information about battery simulation for electronic devices, see this recent post on the SIMULIA blog.

Reparability

In past decades, electronics and machinery were typically modular, and in the event of breakdown could often be repaired by the end user. However, since 2000 the trend towards smaller, lighter devices, among other factors, has led manufacturers to make devices less repairable. Trends such as using glue instead of screws and packaging numerous components on one printed circuit board have reduced the size and weight of devices, but have also made it harder to remove and replace components.

In recent years, the “right to repair” movement – a campaign to allow consumers or independent workshops to repair products ranging from medical equipment to tractors – has seen several successes, and reparability is now an increasing concern. The draft eco-design rules score devices according to how many steps are required to replace parts, the types of fasteners and the tools needed (as well as the availability of spare parts and software updates).[2]

Dassault Systèmes offers a circular economy solution for designing more sustainable devices that are repairable and recyclable.

Learn more

The proposed eco-design regulations laid out in this blogpost mean durability and robustness will be more important than ever in electronic design. To learn more about how simulation can help to meet eco-design targets and sustainability goals, see our whitepaper “Structural Simulation for Consumer Electronics Design”.

References

[1] “Ecodesign and energy labels: EU regulations set to make smartphones and tablets more sustainable”, https://www.izm.fraunhofer.de/en/news_events/tech_news/eu-regulations-set-to-make-smartphones-and-tablets-more-sustainable.html, Fraunhofer Institute for Reliability and Microintegration IZM

[2] Draft of “COMMISSION DELEGATED REGULATION (EU) …/… supplementing Regulation (EU) 2017/1369 of the European Parliament and of the Council with regard to the energy labelling of smartphones and slate tablets”, https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=PI_COM%3AAres%282022%296031464&qid=1666873130618

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW, and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.