How simulation can help improve battery life, durability and safety

From smartphones and laptops to smart home devices and wearables, rechargeable batteries are ubiquitous in electronic devices and systems.

Battery performance has become one of the key differentiators in the consumer electronics market. Customers demand long battery life for their phones and computers, but also want devices that are compact and lightweight. In order to meet these sometimes conflicting consumer requirements, battery engineers need to find the best trade-offs to maximize battery capacity and performance.

The rise of electric vehicles and smart grid storage means that the demand for raw materials is higher than ever. The supply of some materials, such as cobalt, needs to be carefully analyzed and managed with respect to supply chain resilience and sustainability.

Consumer electronics are used constantly and often mistreated. Phones are dropped, shaken, bent, splashed, and used in very hot or cold conditions, and this can be damaging for battery life and safety. Li-ion batteries pack a lot of energy into a small volume of unstable chemicals, and if not carefully manufactured and controlled, the batteries can catch fire or explode.

In this article, we will show how simulation helps design better batteries for electronic devices.

Innovating a better battery

The first commercial Li-ion battery was released in 1991, which makes the technology over 30 years old at this point, but the industry is still not mature. Advancing the state of the art will require either new ways of using Li-ion technology – such as new cell design or novel electrolytes – or commercializing totally new types of battery chemistry.

Some key challenges in battery development include:

- Identifying new electrolytes that are easier to control and more stable. This particularly includes solid-state batteries.

- Cobalt, widely used in battery cathodes, is mostly mined in regions of the Democratic Republic of Congo (DRC). Increasingly strict regulations on conflict minerals mean there’s growing interest in replacing this with another element.

- Fast charging is becoming standard in mobile devices, but it can damage the battery and reduce its life span. There is a real need for batteries that can charge rapidly while also maintaining their performance and longevity.

- Conscious consumers, e-waste regulations and scarcity of materials mean that there is a greater need to optimize the production process, such as the way the slurry is mixed and the potential for recycling scrap.

- The solid-electrolyte interface (SEI) is formed during the first battery charge but determines quality over the entire lifetime of the battery. Can the initial charge be optimized to improve the SEI?

- Battery manufacturers need to scale up massively to meet demand, and promising technologies need to be proven and commercialized. Question marks about production stability and yield need to be resolved.

The development cycle for new battery technology, from concept to commercialization, can be as long as 10 years, but the growing demand from all sectors of industry for better batteries means that there is considerable pressure to reduce time-to-market. Simulation offers a way to significantly accelerate battery development, as new ideas can be tested and optimized virtually without running experiments or build prototypes.

Battery simulation

Battery behavior is multi-domain: It includes materials science and chemistry for understanding the electrolyte, electrodes and their interaction, fluids for the flow of electrolyte, electromagnetics for currents and voltages, thermal for heating and cooling, structures for strength and integrity, and systems analysis to develop the control systems.

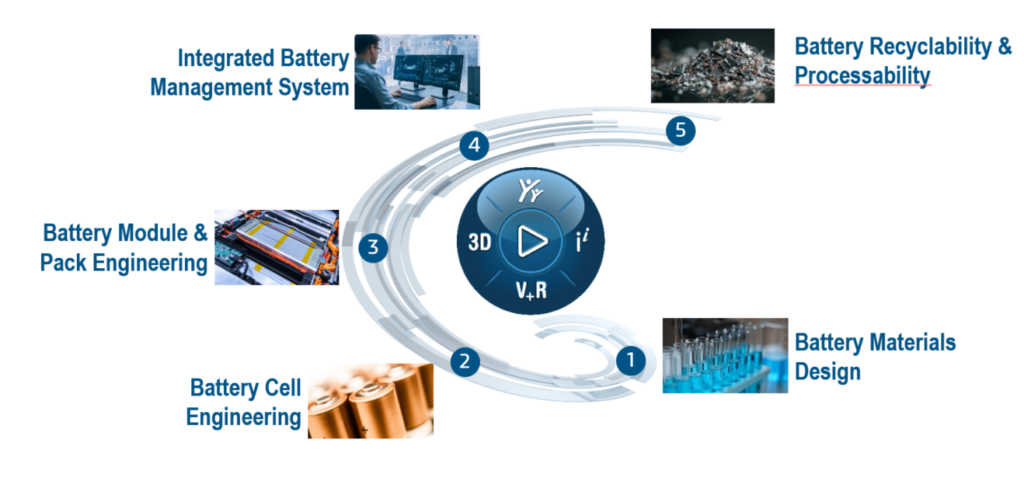

For a typical battery then, the workflow might be as follows:

- Characterize the chemical properties of the battery cell. In the Dassault Systèmes’ portfolio, this can be done with BIOVIA Materials Studio. It provides basic information about voltage, current, discharge relation and inner behavior.

- Construct a 3D model of the jelly roll or cell. Working from a microscope image, this can even include microstructural details.

- Simulate the behavior of the cell. The main electrochemical model for understanding how Li-ion batteries behave is the “Newman model”, which predicts the behavior of the liquid and solid phases of the electrodes. Electrochemical and thermal simulation on a 3D model provides an even more precise understanding of battery behavior, and a prediction of spatial concentration and temperature distribution at any time point.

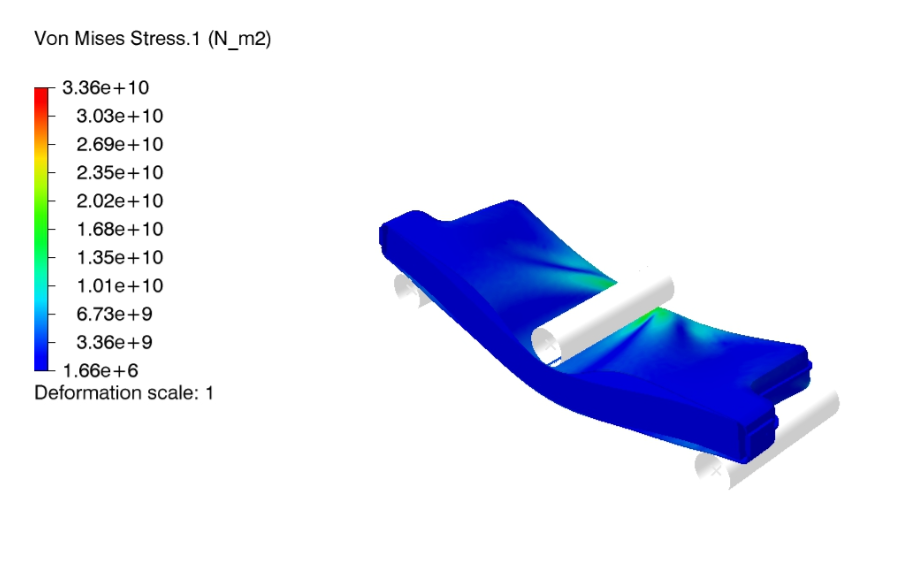

- Investigate potential danger scenarios such as short circuits, thermal runaway and heavy stress loads, as well as the effect of manufacturing constraints and aging degradation.

- Assemble the cells into a battery module or pack. Simulate swelling as a 3D effect and investigate battery safety.

- Simulate destructive scenarios such as drop, bending, water immersion, vibration and overheating, without needing a physical prototype. Pre-defined templates can be leveraged for the democratization of simulation.

- Use simulation to optimize battery module design to reduce weight and improve cooling.

- Transfer simulation data to CATIA for a system simulation using Dymola.

In many cases, this workflow will be split over many departments and even different companies – both the battery cell manufacturer and the device manufacturer have a role to play in ensuring battery integrity, as the forces and temperatures acting on the battery will be determined by the components around it.

Integrating simulation provides competitive advantage

There is a race to understand battery technology and optimize it to meet the growing demands of the high-tech sector. Simulation can provide a competitive edge for engineers working on battery design and integration. For example, the 3D Newman model in SIMULIA enables users to characterize effects that can’t be modeled in other tools.

Battery designs can be optimized and the best trade-offs between KPIs such as weight, energy density and thermal performance can be found. Safety factors can be assessed across a wide range of scenarios, and swelling and degradation effects that often take years to emerge can be identified before even a single prototype is built. Simulation both reduces risk and can significantly cut costs and time to market.

Engineers can work collaboratively to design and test batteries on the 3DEXPERIENCE platform. The close integration of modeling and simulation, as well as templates for test scenarios, democratize simulation so that non-specialists can collaborate and use it in their daily work.

The 3DEXPERIENCE platform brings together BIOVIA, SIMULIA and CATIA solutions in a common environment, allowing collaborative design and analysis. Studies involving different areas of physics can be performed on the same model, using the Virtual Twin approach where a single model replicates the real battery and the same source data is used. The breadth of the Dassault Systèmes portfolio provides the end-to-end tools needed to understand the different aspects of battery performance and develop an optimized design.

Learn more about battery engineering:

- /brands/simulia/how-do-batteries-work/

- https://www.3ds.com/products-services/simulia/solutions/high-tech/battery-engineering/

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW, and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.