Additive manufacturing software has emerged as a groundbreaking technology that is reshaping the manufacturing landscape. Its ability to create complex and customized products with unparalleled speed and precision has captured the attention of industries worldwide. As it continues to evolve and mature, staying ahead of the game requires a deep understanding of its capabilities and integration into lean manufacturing principles. By harnessing the power of additive manufacturing, companies can unlock new levels of efficiency, innovation, and competitive advantage in an increasingly demanding market.

What is additive manufacturing?

Additive manufacturing is an innovative process that builds parts or products by adding material rather than by taking away from it as in CNC machining. Following the programming of CAM/CAD software for cnc machining, with additive manufacturing you can produce the intended part or product design by adding material.

Is 3d printing the same as additive manufacturing?

No. One of the most common forms of additive manufacturing, however, is 3D printing. 3D printing is an additive manufacturing process, but the difference between the two is that additive manufacturing is a broader category that includes a wider variety of processes compared to only 3D printing. Additionally, 3D printing produces parts by adding material layer by layer. Additive manufacturing produces parts by adding material, which may not necessarily be added in layers.

Lastly, additive manufacturing provides efficiency in material usage. It only uses the essential amount of raw materials necessary, minimizing waste, becoming sustainable, and improving its environment footprint.

Providing the power of an integrated platform

The 3DEXPERIENCE platform serves as a comprehensive solution for organizations to connect and integrate their entire ecosystem. This includes people, ideas, data, and processes, all within a single unified environment. By utilizing a unified data model and ontologies, the platform effectively combines knowledge and expertise across various disciplines, ensuring a single version of truth. With its user-friendly interface, the platform offers a simplified and efficient user experience for individuals, teams, and departments, even when working remotely. Additive Manufacturing seamlessly integrates with other applications that will come in handy on the same platform.

These have many benefits for the users, such as:

- Enhanced Collaboration: Being on a connected platform for additive manufacturing allows for seamless collaboration among all stakeholders involved in the process. Designers, engineers, manufacturers, and suppliers can easily share and access data, ideas, and feedback in real-time. This level of collaboration leads to faster decision-making, reduced errors, and improved overall efficiency.

- Streamlined Workflow: With a connected platform, you can streamline and automate the entire additive manufacturing workflow. From design and simulation to short-term production planning and manufacturing quality control , integrate and synchronize all steps, eliminating manual handovers and reducing the risk of errors. This results in faster time to market, increased productivity, and cost savings.

- Data-Driven Insights: A connected platform for additive manufacturing enables the collection and analysis of data throughout the entire process. This data helps gain valuable insight and optimize performance. By leveraging analytics and machine learning capabilities, organizations can identify trends, detect anomalies, and continuously improve their manufacturing processes. This data-driven approach leads to better decision-making, improved product quality, and increased competitiveness.

How DELMIA supports all additive manufacturing needs

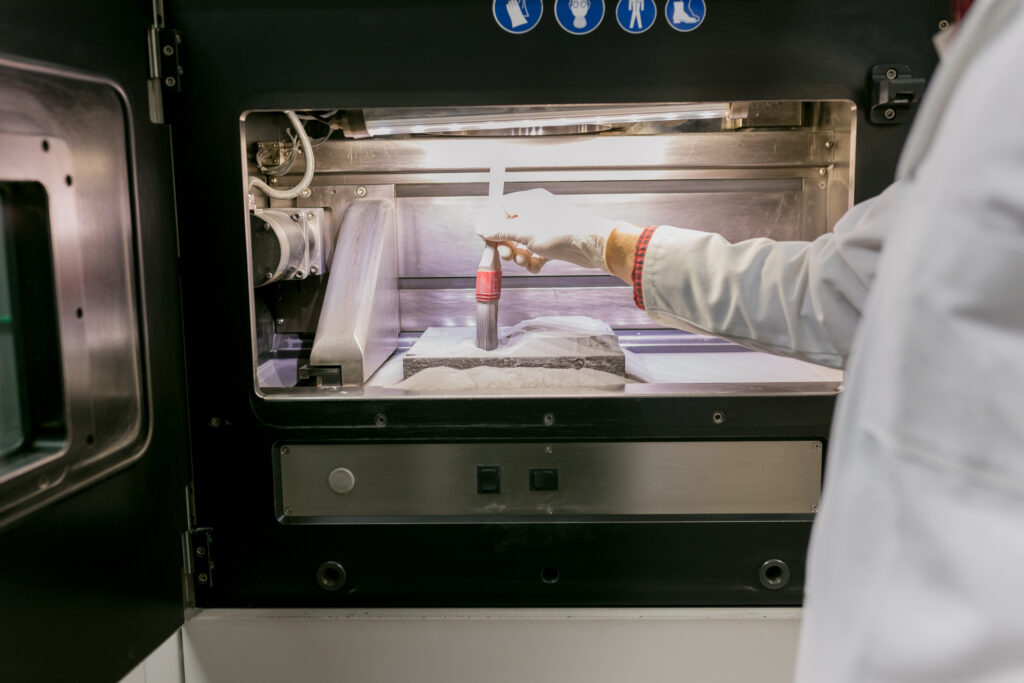

DELMIA CAM software for cnc machining automates and optimizes additive processes for manufacturing business. With a user-friendly interface and powerful features, users can quickly define an accurate and detailed manufacturing build preparation with tools for 3D nesting, supports definition, part labeling and cost estimation.

Its ability to create complex and customized products with unparalleled speed and precision has captured the attention of industries worldwide. As additive manufacturing continues to evolve and mature, staying ahead of the game requires a deep understanding of its capabilities and integration into lean manufacturing software principles. By harnessing the power of additive manufacturing, companies can unlock new levels of efficiency, innovation, and competitive advantage in an increasingly demanding market.

The benefits of DELMIA

These main advantages allow you to:

● Do everything on exact geometry, eradicating errors or deviations due to tessellated formats

● Store technical know-how via rules on virtual machines, making it easy to share and control internally or with suppliers

● Save printing parameters with the parts, which ensure certifications, repeatability and availability during its whole lifecycle, enabling companies to realize mass production and cost reduction

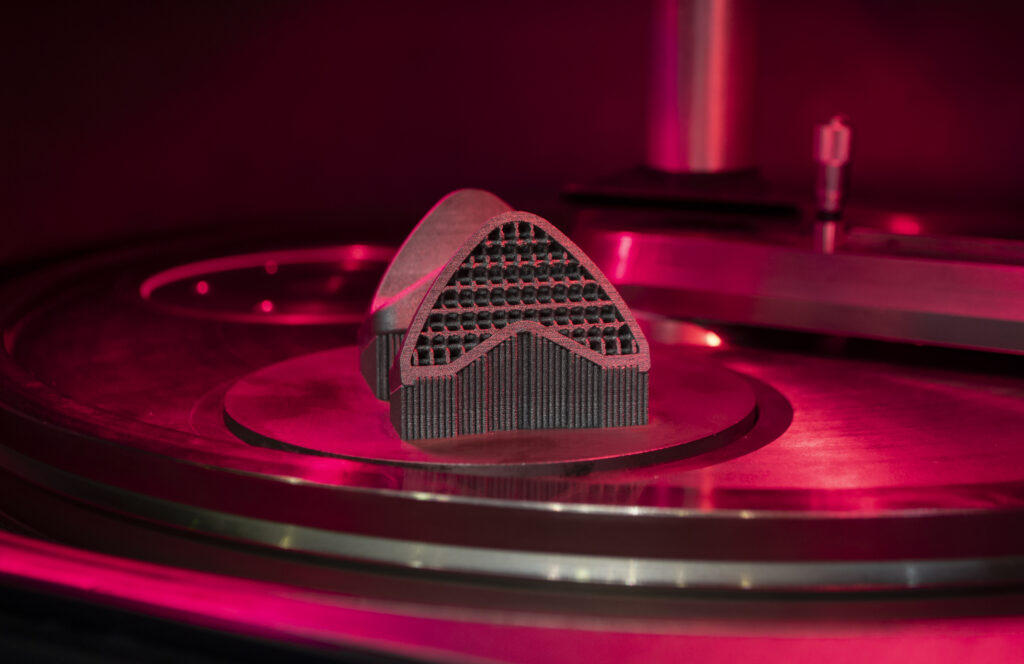

Scan paths based on the 3D geometry are generated to apply appropriate strategies to control quality variables for both parts and supports for printers using one or several lasers. The build plate with parts and supports to be printed are output in 3MF, AMF and STL standard formats. The laser path can also be output under specific printer format for Renishaw, Addup printers as an example. This helps improve quality of the part, mitigate waste, and shorten the time required to print a quality part.

DELMIA equips the users with the necessary programming for most polymer and metal printing techniques including:

● Selective Laser Sintering (SLS)

● Selective Laser Melting (SLM)

● Multi Jet Fusion (MJF)

● Binder Jetting (BJ)

● Electron Beam Melting (EBM)

● Direct Melting Laser Sintering (DMLS)

● Fused Filament Fabrication (FFF)

● Stereo lithography (SLA)

● Digital Light Processing (DLP)

● Multi Jet Modeling (MJM)

● Fusion Deposition Modeling (FDM)

● Laser Cladding

● Direct Energy Deposition (DED)

● Laser Metal Deposition (LMD)

● Laser Engineered Net Shape (LENS)

● Laser or Electron beam wire deposition

With the growing presence of 3D printing technologies, DELMIA software supports all the additive manufacturing needs. Not only will companies benefit from reductions in the cost of material and capital expense, they also achieve the critical agility needed to reduce time to market , improve sustainability, and remain competitive in the industry.

Learn more

Listen to our podcast

Watch the video

Contact us directly to learn more about our products and solutions.