The industry is undergoing a significant transformation with new technologies such as artificial intelligence, augmented reality, and virtual and mixed-reality. These new technologies offer considerable opportunities and advantages to industrial players seeking to adapt to the new challenges of the industrial age and improve their productivity and profitability.

But what exactly are we talking about? What’s behind such technologies?

What is Artificial Intelligence?

Artificial Intelligence (AI) is a technology that enables computers to learn from data and perform tasks that previously required operator intervention. In industry, the AI method is used in various ways. For example, it can automate production processes, monitor equipment or optimize operations.

Using artificial intelligence in the industry

Artificial Intelligence in Manufacturing & Supply Chain can improve industrial efficiency and productivity by predicting equipment breakdowns before they occur, identifying inefficiencies in production processes, and optimizing workflows. The technology also improves product quality by identifying defects in finished products and improving manufacturing quality control software processes.

Operations optimization

This technology improves efficiency and productivity processes and optimizes workflows. Thanks to predictive analytics, AI can foresee problems before they occur, providing plant managers with accurate information on production requirements and stock levels. Automate production decisions to reduce costs while providing users with better quality.

Failure prevention

AI is also a good way of preventing potential equipment failures, as it can monitor equipment performance in real time. Train AI algorithms to detect early warning signs of equipment failure, such as changes in vibration and noise levels. Maintenance teams can then take preventive action to avoid costly downtime.

Improve product quality

We’ve touched on this point before, but artificial intelligence can be a great way to help you improve product quality by identifying defects in final products and enhancing your quality processes. The technology is trained to identify non-conformities or defects in your products by analyzing your production data, quality tests, and customer feedback. AI enables your production teams to be more reactive and to make corrective decisions more quickly if necessary.

Lower production costs

Finally, artificial intelligence can reduce production costs by optimizing raw materials and resources. It can forecast production and supply requirements based on sales history and market trends, thus minimizing production waste and avoiding unnecessary overstocking.

As you can see, using artificial intelligence in manufacturing offers many advantages, particularly with efficiency, productivity, quality, and cost reduction. Using it can improve your profitability, competitiveness, and ability to meet your customers’ needs.

What is Augmented Reality?

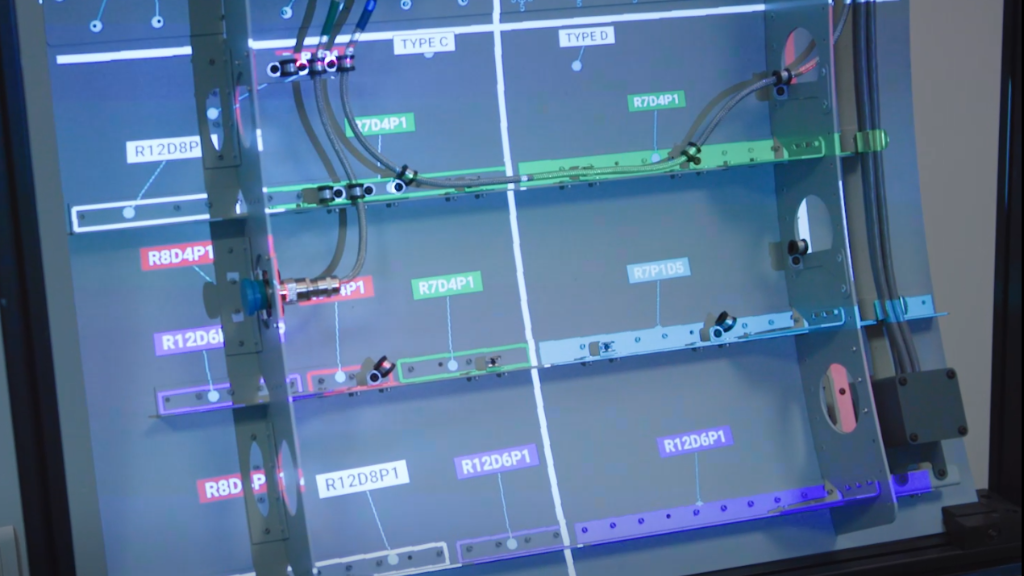

Augmented reality (AR) enables virtual information to be superimposed on the real world. It can help technicians carry out complex tasks in the industry by providing real-time data in their working environment. AR technology uses artificial intelligence to provide object recognition capabilities to facilitate industrial localization and inspection.

Using augmented reality in manufacturing

When applied to industry and the proper use cases are identified, augmented reality can be highly effective in many areas, bringing you a highly relevant ROI.

Skills enhancement and assembly assistance

Augmented reality is beneficial for training your operators and assisting production. Employees can use augmented reality headsets (like hololens, for example) to display real-time assembly instructions and get tips on production processes. Workers can quickly improve their skills and avoid making costly mistakes. Our augmented reality assembly software can also help workers perform complex tasks by providing real-time contextual information, such as distances and angles, for precise assembly tasks.

Maintenance and repair

In addition, augmented reality can improve the maintenance of your equipment by providing digital instructions to guide your operators through repair and maintenance tasks. Equipped with headsets, tablets, or cameras, your technicians can consult digital information directly on the equipment, follow maintenance procedures and carry out repairs faster and more efficiently. Discover our augmented reality industrial maintenance software.

Reduce downtime

Another vital area where augmented reality can help is downtime. Experts in your field can use AR tools to visualize equipment remotely, provide troubleshooting advice and guide your on-site technicians to make the necessary repairs, thereby reducing downtime.

Improve safety

Finally, you can also exploit the capabilities of this technology to enable your technicians to visualize potential hazards, such as danger zones, high-voltage objects, or areas where people are working at height. It also simulates dangerous situations, such as a fire or gas leak, so workers can practice reacting safely.

Transform your industry

Augmented reality in the manufacturing industry offers many advantages, particularly in efficiency, safety, training, and equipment maintenance management software. Industry players can improve productivity and profitability while reducing costs and providing their operators a safer, more productive working environment.

Augmented reality and artificial intelligence are both technologies that offer significant advantages in the industrial sector. Artificial intelligence can automate production processes, monitor equipment, optimize operations, and improve product quality. Augmented reality can help workers perform complex tasks. It provides real-time information about their working environment, improving worker training and the quality of operations on the equipment handled. These technologies used in DELMIA Augmented Experience solutions can help you improve efficiency, productivity, and profitability, while reducing costs and human error.

Both are proven technologies with the potential to meet new challenges and transform your industry.