Originally published in Compass magazine

The global race for innovation leadership in digital manufacturing and broader enterprise operations is accelerating.

Two thirds of industrial companies worldwide now say that digitalizing the production value chain is one of their highest priorities. Successful companies are trying to leverage three major trends:

- Imagining the industry of tomorrow when introducing new tools and agile ways of working. Leaders are almost three times more likely than laggards to use advanced tools, such as augmented reality and virtual reality, and two times more likely to use enabling software, including platforms. They are also five times more likely to have a digital transformation group in place, embracing ‘agile’ in multidisciplinary teams.

- Building and leveraging the power of new players, partnerships and ecosystems. Leaders are developing extended ecosystems that provide full visibility into the entire end-to-end operations process, from initial concept, design and engineering to IoT-informed improvements to the next iteration of a company’s offerings. Through digitalization, this end-to-end visibility provides manufacturing operations with the context, support and inputs on customer requirements needed to develop and manufacture products and services that deliver superior customer experiences. In these ecosystems, product-creating incumbents and startups alike collaborate virtually to ensure digital listening to customer needs and to use 3D models and digital twins for digital creation and virtual testing, before moving to physical delivery.

- Creating new revenue streams through innovative value-added services and new business models. These new streams of revenue not only include pay-by-usage and subscription-based models for equipment and machinery, but also business models that extract revenues and profits from data and insights collected through IoT-connected products, deep knowledge (intellectual property) and know-how (application of IP) through the use of AI, digital twins and virtual worlds.

BEWARE THE ‘PILOT TRAP’

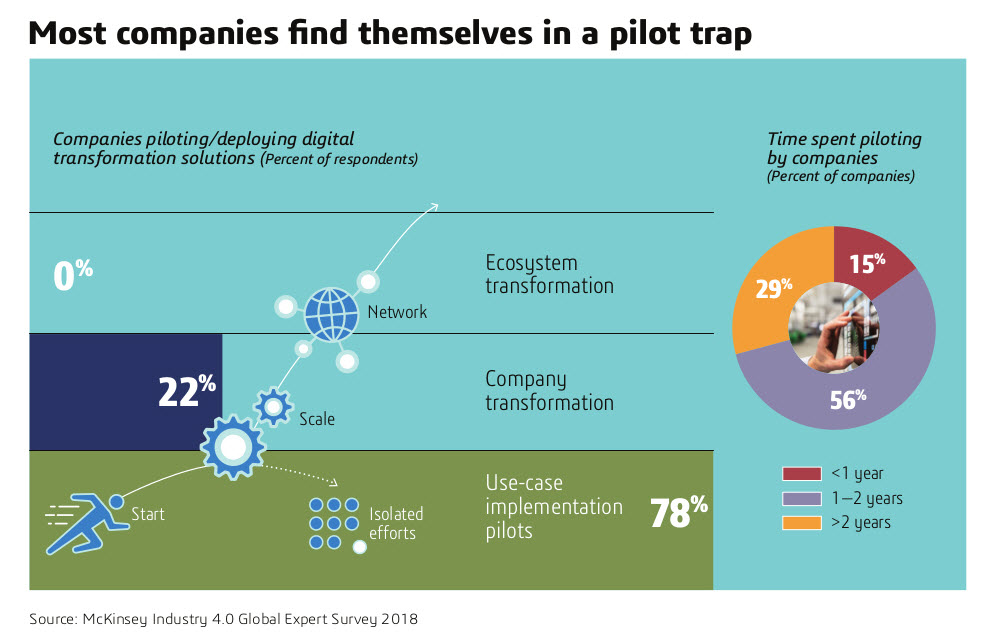

Despite enthusiasm for the potential of industrial IoT, however, McKinsey’s research has shown that many companies are experiencing a “pilot trap” in which they have significant activity underway, but are not yet seeing meaningful bottom-line benefits. Instead, they are struggling to scale up from a portfolio of pilots and proofs of concept to a comprehensive digital transformation that fundamentally changes the entire organization – sometimes described as an “Industry Renaissance.”

DIGITALIZING THE FACTORY FLOOR WITHOUT A BROADER VISION WILL ONLY HARDEN THE SILOS THAT SEPARATE THE PLANT FROM THE ENTERPRISE AND THE CUSTOMERS IT SUPPORTS.” Karel Eloot – Senior Partner, McKinsey and Company

To escape this pilot trap and capture and sustain the value from digital technologies, companies should focus on six success factors:

1. Begin with a clear view on how digital manufacturing solutions can address operational pain points, create competitive advantage and drive bottom-line impact.

2. Design a phased road map based with a clear definition of the size and nature of the business opportunity and a precise understanding of the IT and operational technology (OT) architecture and resourcing requirements.

3. Identify the target-state technology stack.

4. Build and lead a focused ecosystem of technology partners.

5. Ensure that top management drives the transformation.

6. Build an environment that fosters innovation while increasing the capabilities of the organization’s talent.

In short, Industry 4.0 projects will deliver value, but only when they are firmly grounded in a comprehensive digital transformation plan for the enterprise as a whole, including its extended ecosystem. Digitalizing the factory floor without a broader vision will only harden the silos that separate the plant from the enterprise and the customers it supports. ◆

PROFILE

Karel Eloot is a Senior Partner in the Shanghai office of global management consulting firm McKinsey and Company. He co-leads McKinsey’s Asia Operations Practice, as well as the Asia Internet of Things group. His work centers on digitally enabled growth and technology-enabled business transformations in the industrial sectors in China and Asia (high tech, automotive, aerospace, advanced industries, basic materials), including smart manufacturing and plant design, digital product development and procurement, supply chain 4.0, back-mid-front office process automation and IoT architecture and infrastructure.