Dassault Systèmes was a Corporate Sponsor of the Singapore International Robo Expo 2018 (SIRE 2018) on 1 and 2 November 2018, a platform where over 2,000 industry experts, technologists and innovators met, connected and discussed the business capabilities of robotics technology.

Organised by the Singapore Industrial Automation Association (SIAA), the two-day event highlighted the current use of robotics technology in industries such as healthcare and manufacturing, as well as future plans to widen adoption of robotics and automation. A total of 7 symposiums were convened, led by expert speakers on the varied industrial applications of robotics technology, including Adrien Ermenault, Dassault Systèmes’ Regional Manufacturing Solutions Leader for AP South.

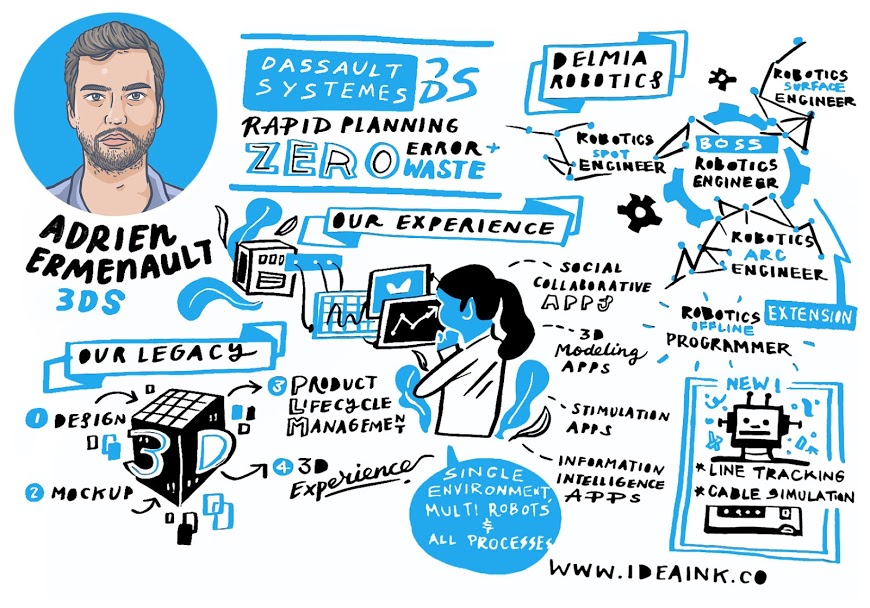

Rapid Planning, Zero Error & Waste

Adrien Ermenault led the huddle discussions during the 5th symposium on “Supply Chain and Logistics Automation. During his presentation on “Rapid Planning, Zero Error & Waste”, Adrien shared how digital continuity with the 3DEXPERIENCE platform, from engineering to shopfloor execution, can help to capture and reuse best practices, leverage program knowledge and automate the repetitive work of robotic programming.

In a perfect world, every product manufactured will end up in consumers’ hands. Unfortunately, that is not the case with manufacturers often having to contend with large amounts of wastage from unused or defective products. Striking a balance between inventory and demand is a delicate science. Too little inventory will result in lower revenues as manufacturers cannot fulfill demand; yet too much inventory will result in needless wastage, not just in too many unused goods, but the resources expended in keeping the production line running for products that will be wasted.

What’s needed is a digitalized integrated solution to intelligently to reach that balance between production and consumer demand, reduce wastage from unused or defective products..

Adrien presented how SOLIDWORKS helps companies streamline their design-to-manufacturing workflows to reduce errors and waste, as well as how DELMIA digital continuity solutions enable maximum production efficiency, lower cost, improve quality and reduce time-to-market. These are critical factors in an increasingly globalized marketplace, where complete and integrated design-to-manufacturing solutions on a unified platform are necessary for companies to stay competitive and minimise wastage.

A graphical sketch chart summarising Adrien’s presentation and huddle discussion points was produced for the SIRE 2018 sketch wall, presenting the participants with a snapshot illustration of how robotics engineers can leverage Dassault Systèmes solutions in 3D design, 3D digital mock-up and product lifecycle management to digitally transform manufacturing processes and achieve rapid planning, zero error and waste in production.

Dassault Systèmes’ Booth at SIRE 2018

Dassault Systèmes’ Value Solutions team, in conjunction with partner, Techmaven Group, exhibited the DELMIA suite of digital continuity and manufacturing solutions. In addition, Dassault Systèmes’ Professional Solutions partner, SEACAD Technologies showcased SOLIDWORKS integrated design-to-manufacturing process solutions.

With the huge amount of investment pumped in by the Singapore government for the research and development of robotics technology, automation and AI, it is indeed an opportune time to be part of SIRE 2018, one of the most important industry events for Singapore’s rapidly growing robotics community.

Missed us at SIRE 2018 or want to meet us again?

For more details about what we showcased at SIRE 2018, contact us at aps.marketing@3ds.com

Register here to hear about our upcoming events, webinars and receive news from our global innovation labs.