Farnborough showcases innovation in flight. As one of the first industries to adopt additive manufacturing (AM), the aviation industry leads the way in demonstrating the benefits of AM. From Boeing’s first FAA-approved 3D printed structural titanium part on its new 787 Dreamliner to Oak Ridge Laboratory’s world record 3D printed carbon fiber extended wing section, aircraft manufacturers continue to develop use cases for additive manufacturing.

As Aerospace and Defense industry veteran, Tony Velocci shares in his Compass article on Additive Manufacturing, the next goal is to transform additive manufacturing production and design processes to deliver consistent quality 3D printed parts on a large scale.

In our Chalet this week, Morf3D, additive design and manufacturing supplier for Boeing and others shares the process of going from powder to certified production part. And Danish shoe maker Ecco Shoes demonstrates the delivery of mass personalization, or production of one, with an on-site process for individualized, 3D printed mid-soles. More companies are moving to 3D printed manufactured parts. It is already changing aircraft manufacturing.

3D printing company Morf3D headquarters El Segundo, California

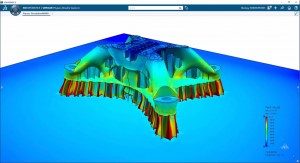

Today, OEMs large and small can design and 3D print more efficient, lighter weight parts. Generative Design enabling technology makes this possible. Watch the videos and see how Functional Generative Design changes 3D printing from a prototype technology into a production technology for delivering certified parts including how to:

- Define specifications such as space, material, lading conditions, targets and constraints.

- Generate multiple printable concepts

- Evaluate and compare concepts vs. key performance indicators

Functional Generative Design allows iterative improvement of the design and printing process with one click

Some of the many rewards for moving to additive manufacturing include:

- Increased design freedom since parts, assemblies and systems can be more complex, yet require less material.

- Improved sustainability of the overall part or system AM reduces material usage and improves parts by making them lighter and stronger.

- Less tooling is required (dies, molds, etc.)

- Lead times are shorter

Like any other manufacturing process, however, additive manufacturing has specific requirements to be followed in the design process in order to produce the part or product successfully. Read this article that provides a look at the development process for successfully manufactured products using additive manufacturing.

The marvels of future Farnborough Airshows will doubtlessly showcase inventions yet to be conceived. The sky is the limit for the potential benefits of additive manufacturing for aviation.