Dassault Systèmes was a Gold Sponsor of the Refining & Petrochemicals World Thailand 2019 conference in Pattaya on January 23 & 24, 2019, where more than 200 downstream professionals met to discuss the industry drivers that are changing the oil & gas sector, notably digitalization, energy efficiency, operations and maintenance excellence, and including plant turnaround management.

Cristina Silva, Dassault Systèmes’ Thailand Country Business Leader, Value Solutions, AP South, was amongst the line-up of prominent speakers during the conference, where she presented on “Digitalization Opportunities in Downstream” during the plenary session.

We bring you a summary by Cristina on Dassault Systèmes’ powerful platform-based approach to digitalization for downstream companies.

Digital platform adoption is key to addressing increasing industry challenges

In recent years, the oil and gas industry has been facing volatility in oil prices and rising costs. In view of these challenges, digitalization has become recognized as a powerful conduit for refiners and petrochemical producers to increase value through improved operational efficiency and sustainability.

There is great untapped potential for digital technologies in the industry. By implementing only point solutions and stand-alone applications, refiners are missing a vast amount of potential value. In fact, not investing in further digitalization to achieve digital maturity poses a major risk in the long-term. Crude oil prices will continue to stay volatile as new energy sources arise. Sustainability issues are becoming even more crucial. Digital platform adoption is necessary for manufacturers to adapt to these industry challenges and help assure long-term profitable growth.

Scalability is essential to future-proof digitalization efforts

To achieve full digital maturity and sustainability, plant owners need to cover all facets of the digital spectrum. This necessitates implementing digitalization strategies that deliver value; for example:

- Asset Lifecycle Management

- Operations and Maintenance

- Planning and Scheduling

- Supply Chain Optimization

- Training for both new hires and experienced personnel

Digital technologies deployed by refineries and petrochemical plants today have been applied in limited areas. Imagine the possibilities when artificial intelligence (AI), machine learning, robotics, big data and on line self-tuning models are successfully applied? These technologies will continue to evolve. Before you know it, self-learning robots powered by AI will help workers to perform maintenance in risky areas. Drones will reduce the need to climb high columns and towers.

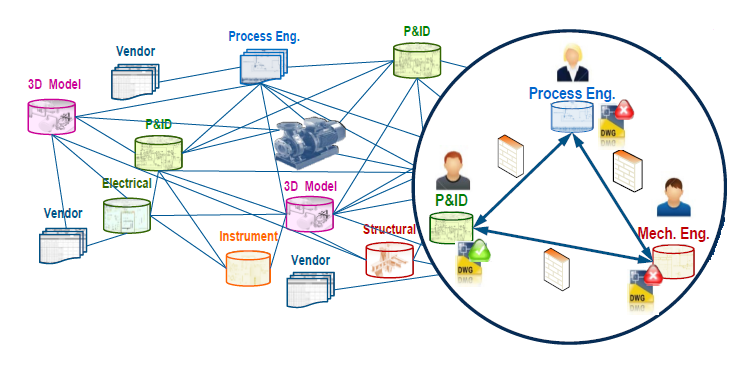

Digitalization programs that companies invest in today need to have the scalability to adapt to new innovations and technologies that will come to dominate the future. This includes the ability to connect 3rd party engineering applications, schedules, drawings and models.

Platform-based approach to digital transformation

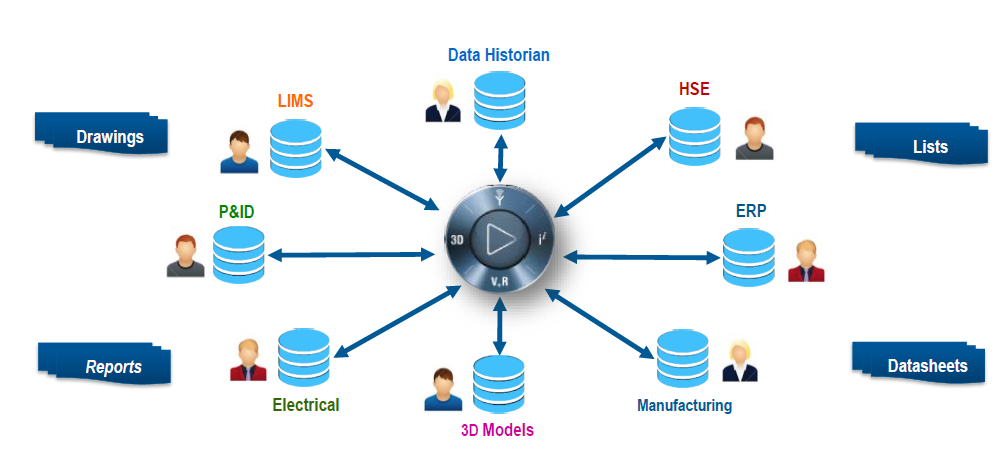

For this reason, Dassault Systèmes deploys a unique platform-based approach to digital transformation. The first step for this platform-based approach is to connect the plant’s apps and data, then streamline these with the plant’s business processes. This interconnectivity facilitates collaboration between the data and the business processes, as well as inter-operability amongst the applications through automated workflows.

Step 1: Apps and data are digitized

Step 2: Digitized apps and data are connected to the refinery’s business processes

Step 3: The interconnectivity facilitates collaboration amongst business processes

Achieving a high level of interconnectivity amongst data sources and business processes is a vital feature for developing a scalable and sustainable digitalization program. What you are actually able to do with the data often hinges on the efficiency of these connections. With easier collaboration and inter-operability amongst data sources and business your team is empowered to deliver greater business value. It is also empowered with better communication creating an eco-system of suppliers and contractors, and full transparency.

When scaling up digitalization programs, this interconnectivity allows refineries and petrochemical plants to derive the full benefits of new technologies on operations and bottom line performance.

Digitalization with the 3DEXPERIENCE platform

Dassault Systèmes’ 3DEXPERIENCE platform takes digitalization programs to a new level, by creating a 3D virtual ‘twin’ or replica of the dynamics and elements of the physical plant; infused with the digitized apps and data, which will be connected to the business processes in automated workflows.

By integrating and mapping all apps, data and business processes in the multi-dimensional virtual environment, Dassault Systèmes’ 3DEXPERIENCE ‘twin’ brings a ‘Single Source of Truth’ for all the plant’s operations and multidisciplinary teams. Because humans are naturally visual and used to navigating the world in 3D, such an approach is the most powerful way to enhance new levels of collaboration and planning amongst people and business processes.

As a powerful enabler of connectivity and collaboration, Dassault Systèmes’ 3DEXPERIENCE ‘twin’ is inherently scalable.

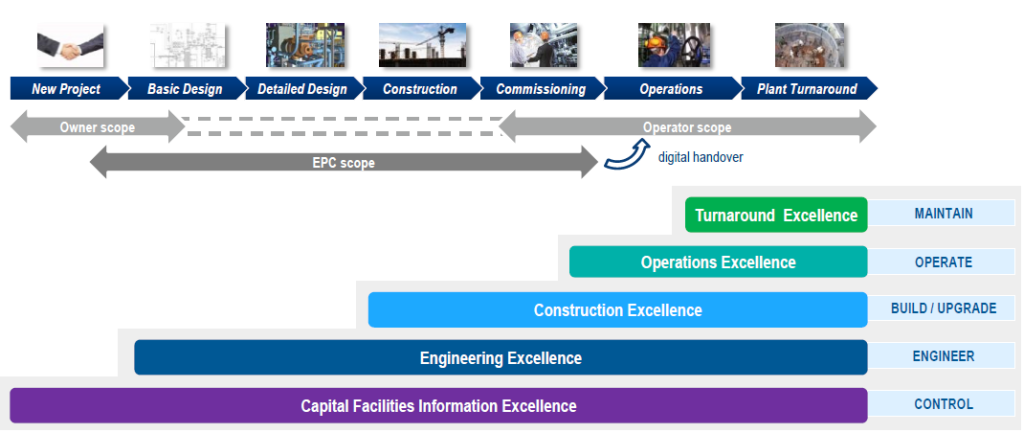

The 3DEXPERIENCE ‘twin’ is able to add on and integrate additional solutions covering the entire lifecycle of capital facilities.

One of the greatest opportunities for downstream digitalization is Turnaround Excellence. Interest in other target areas of operations and maintenance is also increasing.

Dassault Systèmes Integrated Solution Suite for Downstream Companies

On this note, I would like to introduce Dassault Systèmes Integrated Solution Suite powered by the 3DEXPERIENCE platform for Downstream Companies.

1. 3DEXPERIENCE Twin for Asset Lifecycle Management

The 3DEXPERIENCE ‘twin’ is continuously correlated with behavioral data from the assets of the physical refinery. Any enhancements required in the operations is first simulated in the 3DEXPERIENCE ‘twin’, fine-tuned and optimized, before being incorporated in the physical refinery.

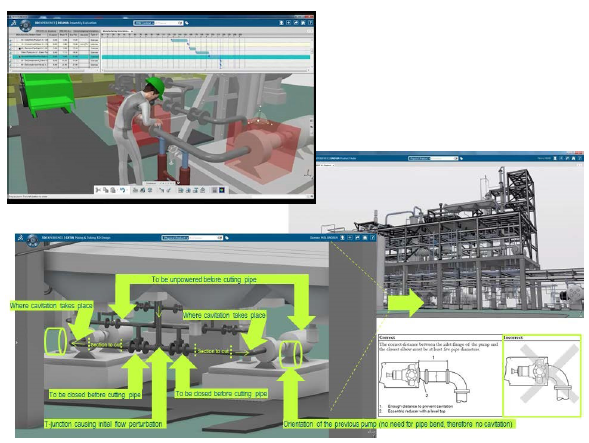

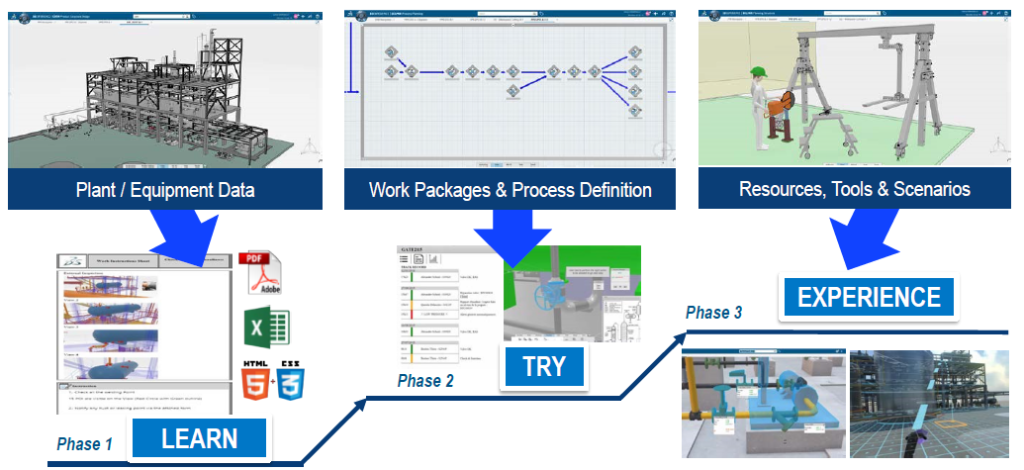

2. 3DEXPERIENCE for Virtual Field Operator Training

The 3DEXPERIENCE platform can be deployed for virtual training of field operations teams. By enabling 3D simulations of various scenarios to test out maintenance procedures, it can help field operators to develop efficient methods of troubleshooting and responding to plant upsets and emergencies.

Importantly, the 3DEXPERIENCE platform enables rehearsal of emergency response situations in the virtual environment to maximize workers’ safety and efficiency.

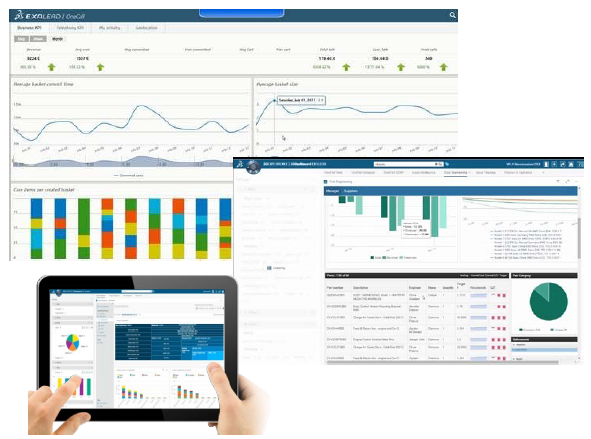

3. 3DEXPERIENCE for Operations Intelligence

The 3DEXPERIENCE provides on-demand data analytics to transform large volumes of multi-source data into meaningful, real-time intelligence information to help make better decisions. It mines the previous data inputted and foresees possible situations and risk, while developing predictive models to explore every possible alternative. The 3DEXPERIENCE interprets the results and data to arrive at meaningful decisions that impact the business.

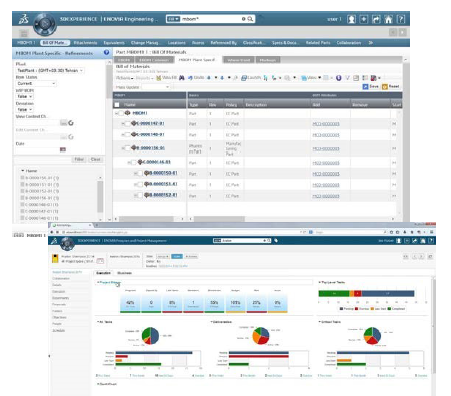

4. 3DEXPERIENCE for Turnaround Project Governance

By offering a ‘Single Source of Truth’ access to real-time data and information, the 3DEXPERIENCE platform improves project governance as all multidisciplinary teams across the facilities collaborate utilizing the same set of data. By consolidating and analyzing data from multiple sources onto one platform, the company is empowered to minimize unplanned downtime, plan, optimize, and schedule resources to improve overall plant efficiency.

Looking for more insights into how the 3DEXPERIENCE platform transforms business operations and processes at leading companies across 11 industries around the world?

Now is your chance to join Dassault Systèmes’ first 3DEXPERIENCE FORUM in Thailand where senior executives will share global industry best practices in digitization for business growth and cultivating an adaptable workforce for business longevity.

Register now for the 3DEXPERIENCE FORUM 2019 in Thailand.

Event Details: Date: Thursday, 21 March 2019 Time: 9:00am to 6:00pm (Bangkok Time) Venue: The Athenee Hotel, Bangkok, Thailand