How do manufacturers navigate the complexity of adding integrated sensors, smart chips, networking capability and software to create innovative, reliable smart devices for the home?

Product complexity keeps increasing

The integration of electronics, mechanical systems, and software in smart consumer devices introduces new challenges for research and development teams. Whether designing a robotic vacuum, or a humanoid robot, automated garden tools, or ebikes and baby gear manufacturers need skilled engineers across multiple disciplines. Intuitively engineering managers know that incorporating connected sensors, cloud computing, software, and artificial intelligence requires real-time collaboration across engineering disciplines.

Quality Drives Market Share

Product quality and reliability are critical to company reputation and market share. Consumers expect easy to use, products that will last – especially for higher priced home automation products. It’s essential for manufactures to deliver high-quality smart home products to protect and grow a their presence in this competitive space.

Embracing platform-based Model-based Systems Engineering (MBSE)

A growing number of companies consider Model-Based Systems Engineering (MBSE) as a critical tool to manage the complexity of systems integration. The ability to apply a ‘systems of systems’ approach is among the many benefits of MBSE. All disciplines (i.e., mechanical, electrical, software, and others) to use what’s known as SysML, or Unifying Systems Modeling Language. Using the SYSML standard language simplifies problem definition and agreement on a solution or solutions.

SysML, Unifying Systems Modeling Language

Using a modeling language that unifies multiple [software] languages is essential. The common language employed by No Magic* users, Systems Modeling Language, known as SysML, allows all project stakeholders to share systems information. By offering a more complete representation of systems, SysML helps reduce errors and ambiguities during systems development processes. (*No Magic was acquired by Dassault Systèmes in 2018)

Trace requirements, align teams

MBSE serves as the framework to enable teams to define and trace product requirements using precise 3D product models from the early concept phase. Using 3D product modeling and virtualization software that uses virtual twins of the future product significantly reduces the need for expensive, time-consuming late-stage modifications. And, a platform-based approach not only helps manages system complexity but also enables collaboration across engineering disciplines and other product stakeholders (purchasing, long-term manufacturing planning software, marketing) so all are aligned and products launch to market faster.

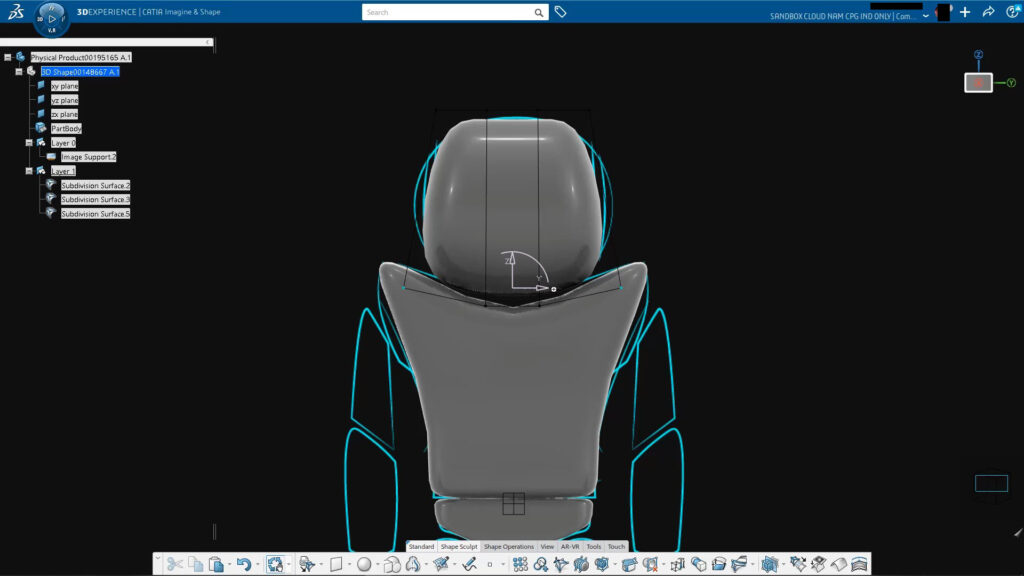

An example of MBSE in action: Building a home robot

MBSE serves as the framework to enable teams to define and trace product requirements using precise 3D product models from the early concept phase. Using 3D product modeling and virtualization software that uses virtual twins of the future product significantly reduces the need for expensive, time-consuming late-stage modifications. And, a platform-based approach not only helps manages system complexity but also enables collaboration across engineering disciplines and other product stakeholders (purchasing, manufacturing planning, marketing) so all are aligned and products launch to market faster.

An Example of MBSE in Action: Building a Home Robot

Using a practical example of the effectiveness of a platform-based MBSE approach, consider the development of a Humanoid robot. A manufacturer developing a new line of human-like robots for the home uses MBSE on a digital platform. This offers engineers to:

- – Use 3D virtual twins of the future product from the concept phase through development and manufacturing;

- – Apply hundreds – or thousands – of simulations on the product virtual twin to optimize the product design;

- – Validate the product design meet requirements (i.e., safety and performance standards);

- – Ensure seamless integration of IoT (Internet of Things) connectivity via Bluetooth or Wi-Fi

- – Seamlessly integrate of components and hardware systems; and

- – Unify multiple [software] languages and integrate software and hardware with SysML.