Consumers care a lot about sustainability. From the cars they drive to the clothes they buy, there’s a trend towards purchasing goods with the environment in mind. And that extends to every aspect of the retail and consumer packaged goods industry. In particular, when it comes to sustainable packaging, buyers have notable opinions.

A 2019 study found more than 80% of UK shoppers were trying to buy less plastic-wrapped produce, seeing it as a wasteful way to purchase goods. More than 60% of consumers were willing to pay more for goods that are sustainably packaged, a 2020 McKinsey study found. While packaging might seem mundane, it’s a crucial component in the final product, and it’s one consumers certainly care about.

The importance of sustainable packaging

To get a product from conception to the hands of consumers, there are about 1,001 steps (sometimes more). From something as simple as a pencil to one as complex as a custom-made kitchen fitting, a lot goes into making consumer goods market-ready, and just as much can go into designing their packaging, too.

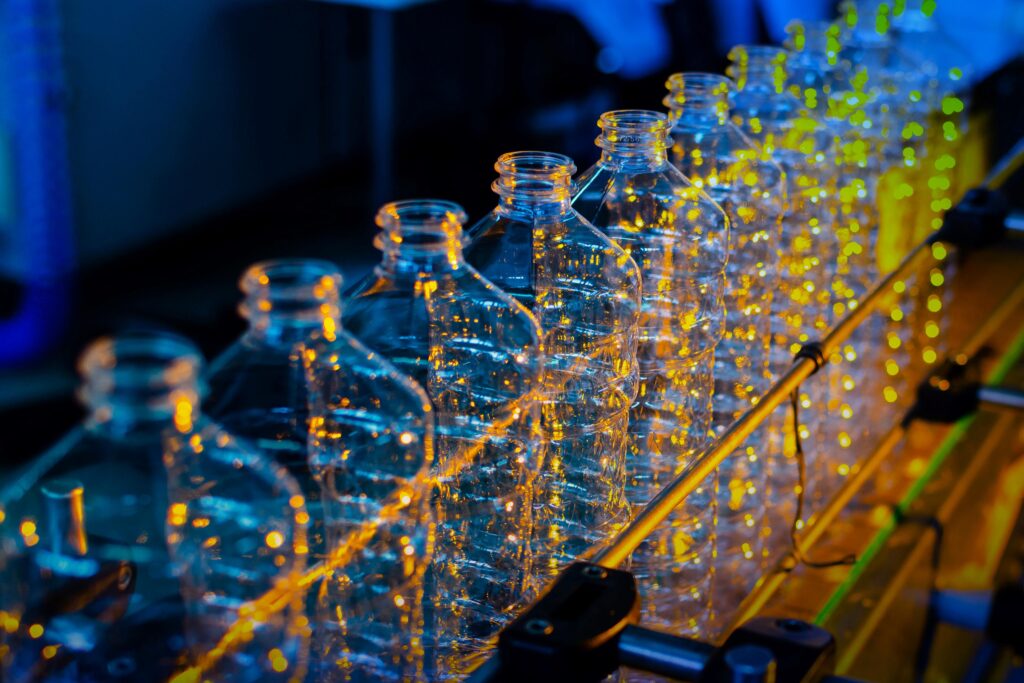

It’s crucial for the bags, bottles and boxes that goods come in to be durable, functional and sustainable.

More and more, companies in the consumer packaged goods and retail space are placing higher importance on creating packaging that’s sturdy and environmentally friendly, and they’re using technology to get there. Just like with product design, using tools like modeling software and virtual twins can make a huge difference in a company’s ability to get a quality product to market quickly.

Introducing technology into the mix

Leaning into the use of artificial intelligence, Coca-Cola recently announced the release of their limited-edition drink Y3000, the recipe and packaging of which were made at the hands of AI.

Just as Coca-Cola’s consumer-friendly foray into AI represents a novel approach into integrating technology into a product we don’t typically think of as tech-y, companies across the food industry are also using tech to increase the durability of their products’ packaging.

One such company was looking for a sustainable way to ensure the packaging of their goods wouldn’t get damaged during shipment or on the supermarket shelf. They turned to technology — and Dassault Systèmes — to get the job done.

By using SIMULA’s Abaqus solution, they were able to undertake testing for their packaging without the need for physical prototyping. The company used Abaqus for different simulations to glean necessary information for designing the right thickness for a plastic package and then, later in the process, conducted further simulation to evaluate performance and optimize accordingly. Using design and simulation technology, the company produced a superior result without creating waste along the way, saving them time, money and product.

How does sustainability fit in?

If you’ve shopped the aisles of your local grocery store, you’ve likely found yourself eyeing a product packaged in a box, bag or bottle made by Amcor. From ketchup bottles to coffee canisters, they’ve got a hand in every aspect of the market.

The company, a global powerhouse in the packaging space, has been employing virtual twins to sustainably create plastic for over 15 years. By virtually prototyping their products with Abaqus, the company has been able to produce lighter-weight plastics that are equally as durable as their heavier counterparts. Designing plastics made of, well, less plastic, Amcor is creating the same amount of quality goods but with less waste.

Efforts like these by Amcor and Coca-Cola indicate their understanding of their customers’ interests and expectations when it comes to sustainable packaging.

Companies have every reason to work toward implementing sustainable packaging into their practices. With solutions like virtual twin design programs, they have the resources to do so as well. While we might not often think of technology as being an essential part of the “recipe” for the goods we buy, it plays a significant role in getting those products from conception stage to our carts.

Designing sustainable packaging that’s functional, durable and recognizable is a challenge for manufacturers, but not one that’s impossible to overcome. This is especially true when technology is leveraged. Deploying tools like AI and virtual twins can help companies innovate faster, stay ahead of the competition and create sustainable packaging for all types of goods. At the end of the day, it’s what consumers want.