By Matthias Meienhofer, SIMULIA Brand Sales ASEAN and ANZ, Dassault Systèmes

Developing products is a highly complex task that involves multiple departments, stakeholders, and tools. A large amount of information and data needs to be exchanged, and it can take weeks or up to months to arrive at initial designs. Traditionally, companies adhere to a “linear approach” for product development.

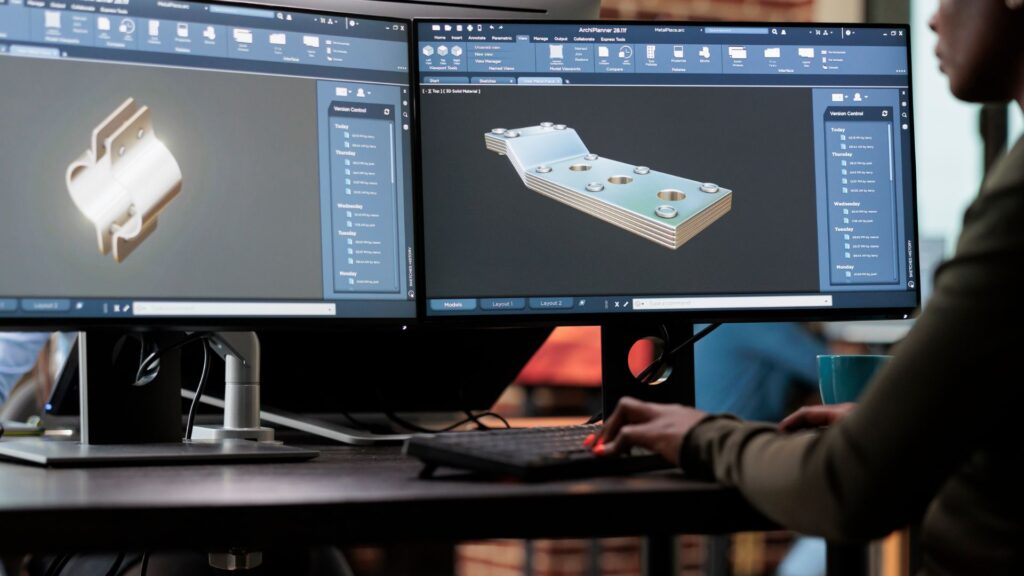

Once CAD data is created, it is passed on for geometry clean up. From there it is moved to meshing and thereafter again passed on for simulation and analysis. If along the way an issue emerges, the progress gets obstructed and one has to loop back and go through all the steps again. Overall, with this approach the development process is at risk of becoming lengthy, expensive, and inefficient.

One source of inefficiency is complexity, which has various origins. The three typical ones are corporate complexity – from the sheer number of engineering systems and stakeholders involved; product complexity – from the presence of thousands of parts in the product; and CAE-workflow complexity – since they typically replicate complex physical tests.

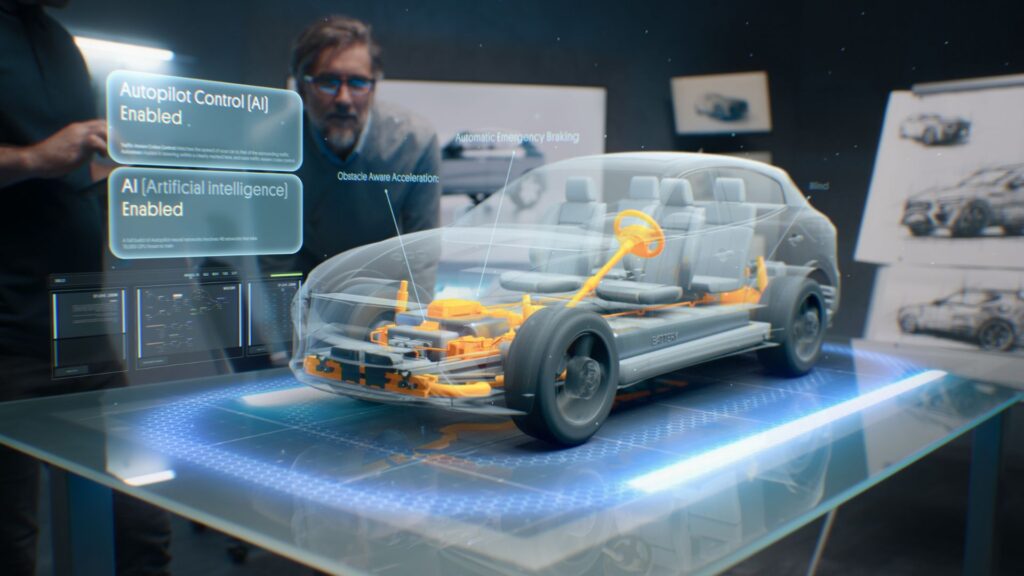

Companies use CAE solutions to carry out complex analyses in the virtual rather than real world. This offers greater and quicker insights into designs and product performance while simultaneously reducing the number of required physical tests and prototypes, ultimately reducing costs. Dassault Systèmes has been investing in simulation technology for decades, building a multi-physics, multi-scale product portfolio to drive innovation in the development of products such as EVs.

The 3DEXPERIENCE Platform dramatically transforms product development

Dassault Systèmes MODSIM approach manages complexity and improves efficiency by combining modeling and simulation on a common data model, within a single user experience on the 3DEXPERIENCE Platform.

“MODSIM empowers companies to efficiently navigate the complex landscape of electric mobility, driving innovation, and advancing sustainable transportation.”

On the platform, project stakeholders with various skill sets and backgrounds from designers to engineers and project managers can collaborate in one and the same environment.

Design changes made in one place are automatically updated and propagated throughout the platform. Thisisunlike in the traditional linear approach where a change at any stage necessitates looping back a few steps and going through the steps again. Leveraging integration and automation, you can quickly advance from the conceptual design stage to design analysis, significantly shortening the entire product design process.

You can address issues collectively and share results with colleagues conveniently, reducing the number of communication paths, file exchanges and meetings. On the platform, each stakeholder has a defined set of roles available to him, which encompass all the required functionality to carry out the tasks the stakeholder is responsible for.

The 3DEXPERIENCE Platform democratizes technology. It provides a simple, elegant, and efficient solution for the entire organization, suitable for both experts and non-experts. Beyond modeling and simulation, the platform offers other capabilities, such as change or requirements management functionality and tools for project management, covering the entire product lifecycle.

MODSIM streamlines the product development process and makes the CAE journey short, affordable, and efficient by leveraging the 3DEXPERIENCE Platform.

Join us to learn more about the 3DEXPERIENCE Platform and MODSIM

Hear from Matthias Meienhofer at the replay of the 3DEXPERIENCE Forum Asia Pacific South 2023. Explore how fostering inclusive innovation, leveraging Virtual Twin Experiences, and cultivating a collaborative environment can drive breakthroughs and address pressing challenges.

A comprehensive and collaborative environment for everyone

Designers can access the necessary tools and capability to create 3D computer models of products on the 3DEXPERIENCE Platform. There, they can also leverage simulation tools suitable for early design stages, offering what we may refer to as “coarse” simulations. Essentially, the 3DEXPERIENCE Platform enables designers to create product designs and identify critical failures in early development stages.

Engineers, on the other hand, have access to more sophisticated simulation tools and capability that build upon the designer’s work. The 3DEXPERIENCE Platform helps them to carry out in-depth simulations. The platform empowers structural mechanics, fluid dynamics, and electromagnetics engineers to carry out in-depth analyses of designs, which ideally confirm the designer’s findings and help further improve product performance. At this point, critical failures should have already been addressed or ruled out in the earlier design stages.

Although the physics behind the simulation may vary depending on what type of analysis is being carried out, the collaborative framework within which they work remains the same.

“MODSIM helps organizations to accelerate product development, while preserving the freedom to innovate.”

Seamlessly enabling multi-physics and multi-scale workflows based on real-world validated and calibrated technology, Dassault Systèmes’ 3DEXPERIENCE Platform represents an end-to-end solution for product design. With the MODSIM approach, companies can shorten time to market and gain a definitive competitive advantage.