This post is a continuation in a series about simulation on the 3DEXPERIENCE platform and some of the roles you can find there. This week we are focusing on the Fluid Dynamics Engineer Role and how it allows engineers who perform routine fluid flow and thermal calculations guide design modifications and explore innovative design concepts.

Overview

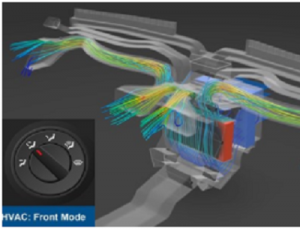

Fluid Dynamics Engineer provides designers and design engineers with the ability to validate fluid and thermal performance for internal/ external flows and conjugate heat transfer problems. With a CAD-enabled CFD approach, Fluid Dynamics Engineer enables users to quickly explore 100s of designs while concurrently improving product performance based on optimal flow distribution, efficient thermal management, minimal pressure losses etc. Fluid Dynamics Engineer leverages industry standard RANS based finite volume Computational Fluid Dynamics (CFD) technology with an integrated (CAD+CFD+PLM) and fully guided user experience tailored for Designers to perform end-to-end product design efficiently on a single collaborative environment of 3DEXPERIENCE Platform.

Fluid Dynamics Engineer benefits from Simulation Data Science capabilities enabling all simulation activities, models, and results to be linked, traced, updated, re-used, and analyzed with ease by all impacted users.

Fluid Dynamics Engineer (FMK) includes embedded compute licensing allowing routine execution of one concurrent simulation job on up to 8 cores. Embedded compute is inseparable from its associated role. Access to embedded compute follows the same Named User or Concurrent license model as the role it is associated with.

Fluid Dynamics Engineer inherits the value of either of the following Platform Options as pre-requisites:

- Simulation Foundation (SEI) provides apps and services that allow all users to access the corporate library of deployed simulation methods and benefit from a single location to find and monitor all of their simulation studies. See the Simulation Foundation or Multidisciplinary Optimization Engineer BFS documents for more information.

Multidisciplinary Optimization Engineer (MDO) Multidisciplinary Optimization Engineer As a Role on the 3DEXPERIENCE Platform, Fluid Dynamics Engineer permits a seamless switch between applications, allowing users to be product-focused: applying the right tool at the right time in their workflow processes. This allows a much greater degree of flexibility and collaboration in the design and simulation process, where geometry changes are automatically updated and made immediately available on the same platform for the analyst to obtain updated results.

There are two key components to Fluid Dynamics Engineer which capture the CFD work flow processes: Fluid Model Creation and Fluid Scenario Creation.

- Fluid Model Creation allows the user to easily build high-fidelity meshes for fluid flow calculations, which accurately capture boundary layers and automatically extract the fluid domain, thus reducing the need for most manual preparation.

- Fluid Scenario Creation allows the user to define the fluid properties and the physics/boundary conditions that define the simulation scenario.

Fluid Dynamics Engineer benefits from the Simulation Data Science capability enabling all simulation activities, models, and results to be linked, traced, managed, updated, published, re-used, and analyzed with ease by all impacted users.

If used together, Fluid Dynamics Engineer (FMK) inherits all of the values of the Multidisciplinary Optimization Engineer (MDO) allowing the user to develop re-usable, deployable simulation processes, enabling simulation value to be experienced as an integral part of your product development activities.

Key Capabilities There are two key components to Fluid Dynamics Engineer, which capture the CFD work flow processes: Fluid Model Creation and Fluid Scenario Creation.

- Fluid Model Creation allows the user to easily build high-fidelity meshes for fluid flow calculations, which accurately capture boundary layers and automatically extract the fluid domain, thus reducing the need for most manual preparation.

- Fluid Scenario Creation allows the user to define the fluid properties and the physics/boundary conditions that define the simulation scenario.

Role Capabilities

- Steady state and transient flows

- Laminar and turbulent flows

- Internal and external steady state fluid flow with automatically selected turbulence model Advanced body-fitted meshing capability made easy-to-use with automatic Hex-Dominant Mesh (HDM) enabling users to accurately capture flow over complex geometric surfaces

- All speed solvers

- Incompressible and compressible flows

- Subsonic, transonic and supersonic

- Newtonian and non- Newtonian flows

- Multispecies modeling

- Free surface flows (VOF)

- Native conjugate heat transfer

- Surface-to-surface and Solar Radiation

- Human thermal comfort model

- Joule heating, thin film modeling (de-mist, de-fog)

- Fans and baffles

- Porous Media, Multiple rotating frames (MRF)

Benefits

- Designer-level steady state CFD does not require extensive specialist-level simulation knowledge or experience

- Intuitive interface utilizing a dedicated User Assistant for CFD set-up requires minimal simulation knowledge

- Improve designs to optimize flow distribution, minimize pressure loss and turbulence.

- Reduced complexity of CFD workflows on a variety of flow scenarios

- Internal flows such as pipes, valves, and ducts with automatic fluid domain extraction, and external flows such as buildings and vehicles with automatic creation of bounding surface of fluid domain

- The dedicated workflow guides users through the principle steps in a CFD and Conjugate Heat Transfer (CHT) simulation giving novice users the ability to set-up and successfully run such a calculation

- Accurate results for complex boundary layer problems and turbulent flows

- Hex dominate meshing with body fitted prism layers provide a higher fidelity simulation for convective flows with accurate capture of the boundary layer to in turn provide accurate wall shear stress and drag calculations

- A suite of standard turbulence models, including k-ω SST and Realizable k-ε, are available to capture the effects of turbulence, as well as a hybrid near-wall treatment to accurately predict boundary layer flows independent of near-wall mesh density

- Reduce computational time for steady state and mildly transient problems

- The steady state solver significantly reduces computational time for inherently steady state flow conditions and conversely, the transient solver accurately captures time varying flow behavior such as vortex shedding

Highlights

- End-to-end workflows with CAD-enabled CFD for concurrent simulation and design

- Reduce complexity for common fluid analyses with dedicated User Assistant

- steady state and long transient fluid flow and heat transfer problems with automatically selected turbulence model

- Easy-to-use intuitive interface including an active assistant to guide the user through what to do next

- Trade-off performance to execute faster early in the design

- High performance results visualization and automatic report generation

- Includes computation on up to 8 cores that may be extended to take advantage of high performance computing to reduce compute time

- Use simulation to validate KPIs and product requirements and perform trade-offs

- Select pre-defined rules based on the type of simulation being performed to improve simulation efficiency, robustness and accuracy

- Industry standard RANS (Reynolds Averaged Navier-Stokes) based finite volume solver for steady state and low frequency transient flow simulations

- Advanced body-fitted meshing capability made easy-to-use with automatic Hex-Dominant Mesh (HDM) enabling users to accurately capture flow over complex geometric surfaces

- User assistant for guiding users to seamlessly navigate from model setup through results post-processing

- Patented Error estimator technology for accurate prediction of convergence errors reducing wasted iterations and hence, solving the simulations to convergence faster

- Multiphysics enabled: Fluid-Structure Interaction (FSI) and native Conjugate Heat Transfer (CHT) for modeling complex flow simulations involving multiple domains

- Unified environment for pre-processing, solve and post-processing

- Leverage simulation model prep tools for typical geometry clean-up within the same environment

- Setup DOE loops and deploy re-usable simulation processes to explore alternatives at early stages and finalize design with comprehensive result analytics

What’s New

The Fluid Dynamics Engineer role in 2022x GA includes one major enhancement that reduces turnaround time for capturing thermal response of electronics cooling assemblies using reduced-order flow and thermal modeling to mimic behavior of electronics cooling components such as thermo-electric coolers, compact heat sinks and printed circuit boards.

Don’t miss the next post in this series where we introduce the Plastic Injection Engineer Role!

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW, and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.