This article was originally published in February 2017.

Modeling Ski Strength with Abaqus

Let me tell you from personal experience, living in the northern United States during the winter can be a cold, dark and snowy existence. But a skier would say bring on the fresh white powder because it’s ski season! Every skier looks forward to driving up to the mountains on the weekend in a car packed with friends and family, homemade lunches, extra socks, and of course, their skis.

Let’s consider the skier’s primary tool: the ski. According to an interesting BBC article, the ski was actually invented before the wheel and allowed our early ancestors to travel during the winter and hunt animals across frozen terrain. Over the past 20,000 years, skis have seen an amazing evolution which has only accelerated in recent time.

The goal of ski producers today is to create skis that are stiffer and stronger than their predecessors. To that end, designers have worked wonders with the design and material composition of the modern alpine ski. What originally began as simple wooden planks has evolved into the stretched hour-glass shape we are now familiar with. This new shape allows the skis’ geometry to aid in turning and control. And while many alpine skis still contain a wooden core, they are now constructed from a wide range of materials including wood, foam board, fiberglass, Kevlar, aluminum, steel, nylon and a material known as P-Tex.

Despite incredible advances in technology, some skiers still find that their skis simply loose “power” or “spring” over time. This can often be attributed to a degradation of the material, which results in a loss of stiffness. Skis with a reduced stiffness are less responsive to the skiers’ efforts to maintain direction and control―not an ideal situation when going down a double black diamond!

Can finite element analysis help determine if your skis are losing their spring?

Image courtesy of “Finite Element Analysis of the Stresses in a Modern Alpine Ski” by David Scott Grant

Skis are engineered to withstand constant stresses, but repetitive abuse/fun may pose a threat to a ski’s material integrity. We recently stumbled across a paper written by avid skier and engineer, David Scott Grant, which explores this topic in depth.

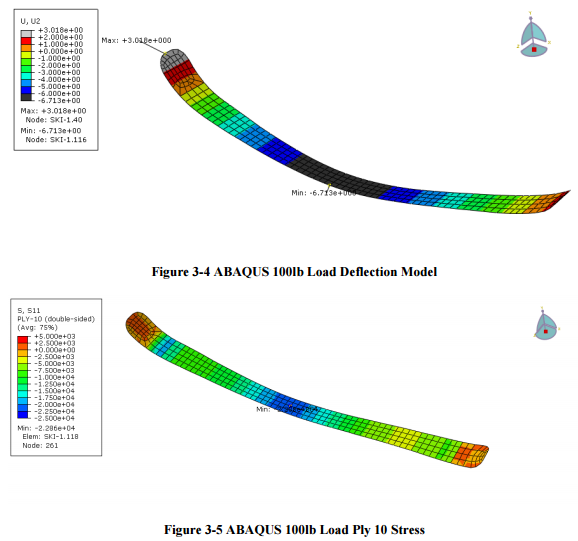

The paper, “Finite Element Analysis of the Stresses in a Modern Alpine Ski,” discusses the latest alpine ski technology and the damaging effect of skiing over a small trench or gully in the off-trail glades.

David modeled a modern alpine ski, consisting of multiple layers of composite materials, under various stresses over a three year period using the finite element analysis (FEA) capabilities of Abaqus software. He even verified the validity of the model by comparing it to real world testing on his personal skis!

David’s study shows that, through the use of realistic simulation technology, it is possible for designers to virtually test skis and overcome design challenges before ever hitting the slopes.

Want to Learn More?

Discover how simulation technology is revolutionizing the consumer goods industry by helping companies produce a better product while saving time and money.