An automotive executive once told me no one would ever look at a car and say, “That’s clearly a product of superior information technology.” His company went bankrupt.

Times have changed. It takes more lines of code to control a modern passenger car than a commercial aircraft or Facebook, and that’s before considering autonomous driving. Perhaps even more important is the extraordinary amount of software needed to design and manufacture a vehicle. Typical vehicle programs employ thousands of engineers using CAD systems to define geometry, physics simulation tools to verify performance before building any physical prototypes, and manufacturing software to optimize plant operations and supply chains.

Despite this mountain of digital infrastructure, automotive product development is nowhere nearly as efficient as companies would like. For example, it takes the average vehicle manufacturer several weeks just to build detailed vehicle simulation models after a design milestone and then several weeks more to create and assimilate results from the appropriate simulations. These delays not only influence overall vehicle development time, they also cripple design exploration and innovation. Imagine learning to play the piano where you have to wait a month between pressing a key and hearing the resulting note. This is what it is like to use simulation with month-long delays to understand how a product behaves. For simulation to have maximum impact, it must facilitate rapid experimentation with key parameters to identify optimal and robust design solutions.

It’s no surprise, there is strong interest among automotive OEMs to get design and simulation teams working together more efficiently. In fact, EV startups around the world are showing the way. Without the overhead of decades of legacy tools and processes, they are taking a page from software engineering and creating more agile development teams. Almost universally, they are leveraging the 3DEXPERIENCE platform to realize collaboration and efficiency impossible in traditional development environments.

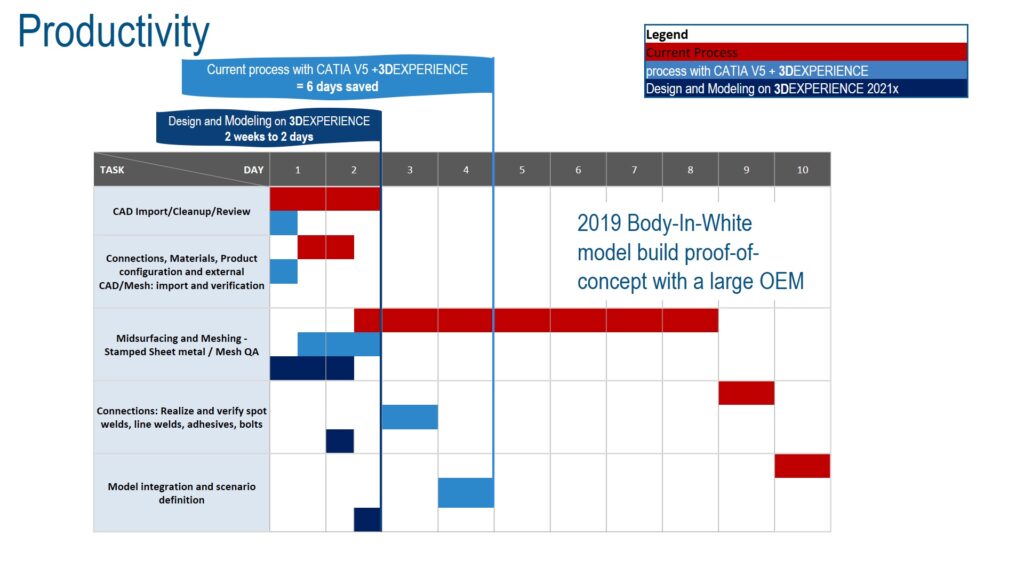

Using the 3DEXPERIENCE platform with its combination of design-simulation associativity and automated mesh, fastener, and configuration management, we are able to dramatically improve simulation model-building time by as much as a factor of five (Figure 1) with further improvements to come.

Digital Continuity and Collaborating Across Silos

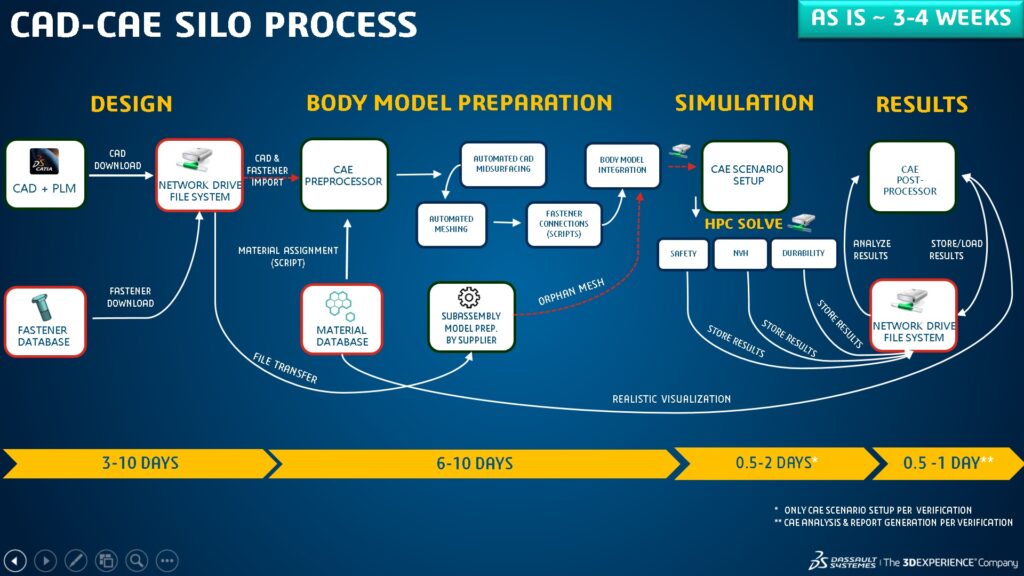

Focusing on body engineering, we can see in Figure 2 some of the current challenges. First, disconnected tools exacerbate silos between design, engineering, and manufacturing. Below is a typical schematic of the as-is body engineering landscape at most OEMs.

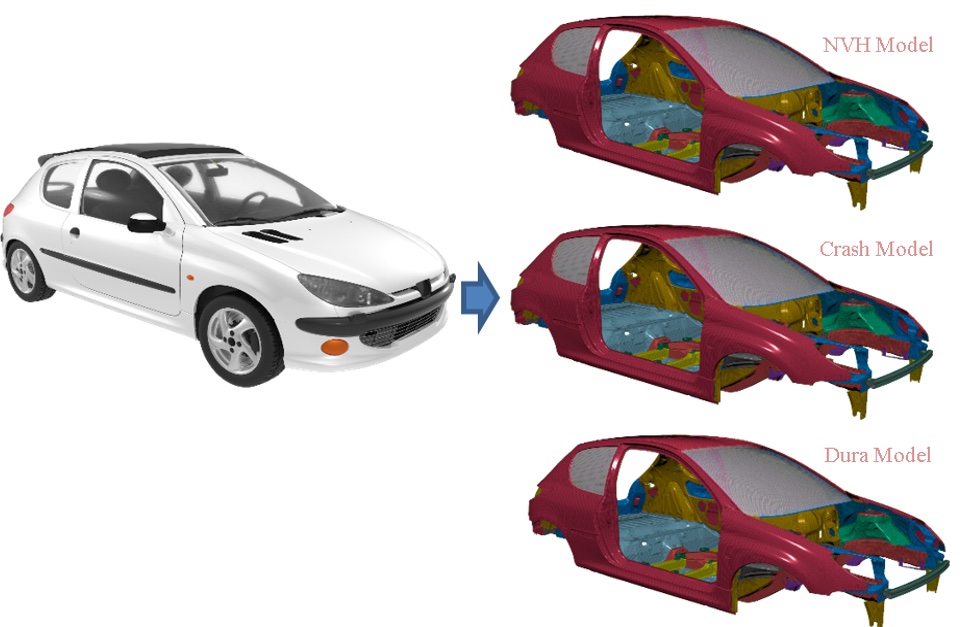

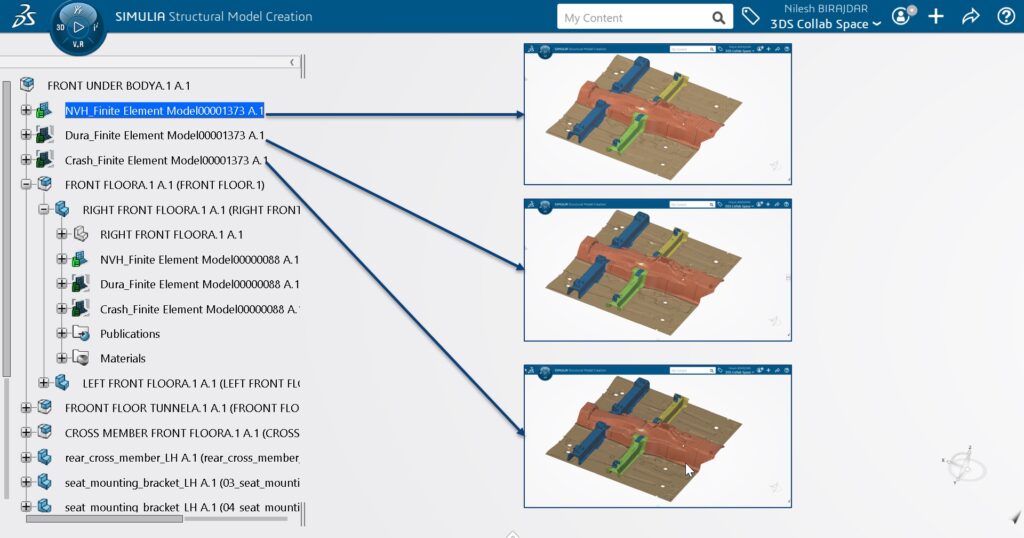

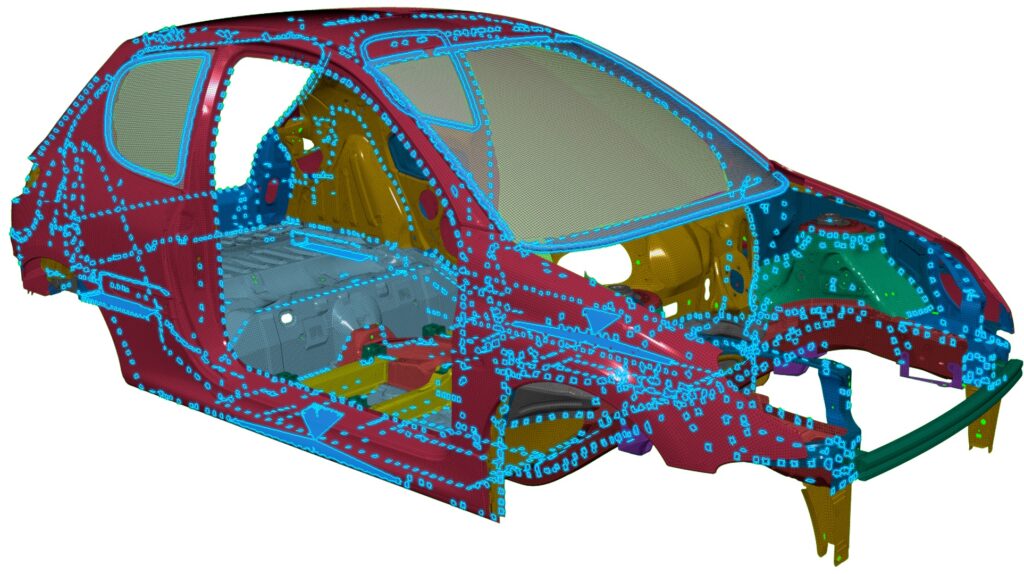

Maintaining model traceability and continuity between design and simulation remains a big obstacle to productivity. The 3DEXPERIENCE platform addresses this with a single, master model (Figure 3) for all structural attributes from which you can automatically derive appropriate models for crash, NVH, and durability, as shown below.

The 3DEXPERIENCE platform can create finite element meshes automatically from CAD data. From the same design, you can manage multiple mesh representations with different mesh densities and geometry simplifications (removing fillets, ignoring small holes, etc.) for various types of simulations. The meshes are associative with the design geometry so you can update a model following geometric modifications without having to recreate analysis attributes. You can automatically mesh large assemblies of hundreds of shell parts using the rule-based batch meshing technology.

A typical modern vehicle body may have up to 500 parts and 5000 fasteners. The latter is a combination of spot welds, line welds, rivets, bolts, and adhesives, as indicated in the picture below.

To achieve performance with minimum cost, OEMs have a keen interest in optimizing the fastener layout. However, maintaining separate repositories of fastener information among design, simulation, and manufacturing, data is often unsynchronized or missing for one or more teams. In addition, even within the simulation organization, there is a need to manage multiple representations of fasteners for different performance attributes. For example, a spot weld for NVH simulation does not need to predict failure, whereas the same weld in a crash simulation may separate. With the 3DEXPERIENCE platform, you can manage multiple fastener representations for different attributes.

Finally, multiple configurations of the same vehicle may need simulations for the same requirement. The 3DEXPERIENCE platform allows you easily to filter designs based on vehicle configuration and then automatically generate the appropriate simulation models.

Requirements-driven Simulation

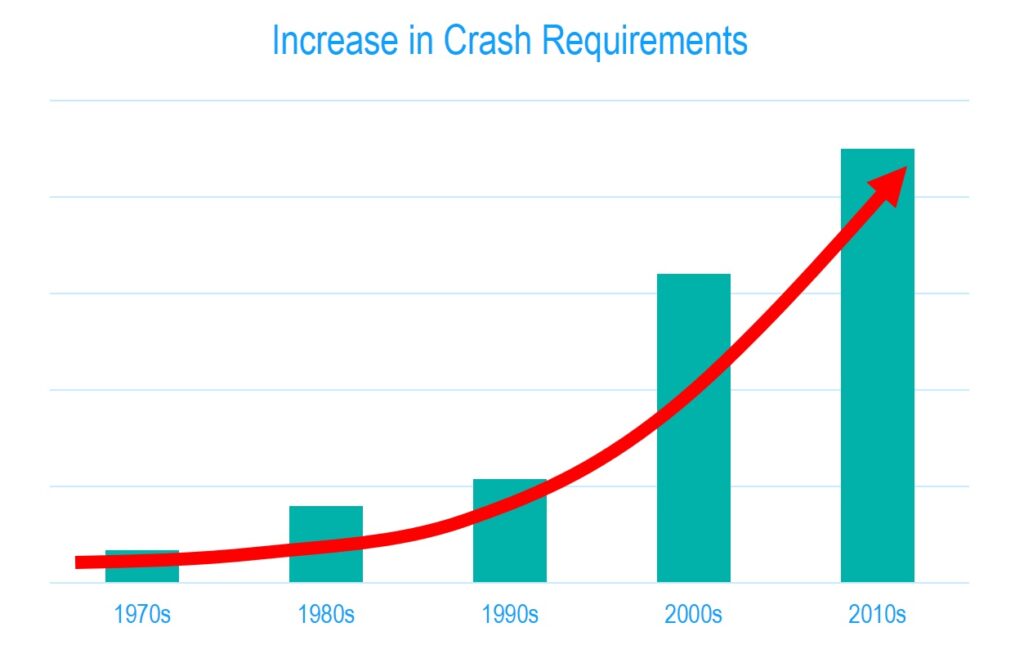

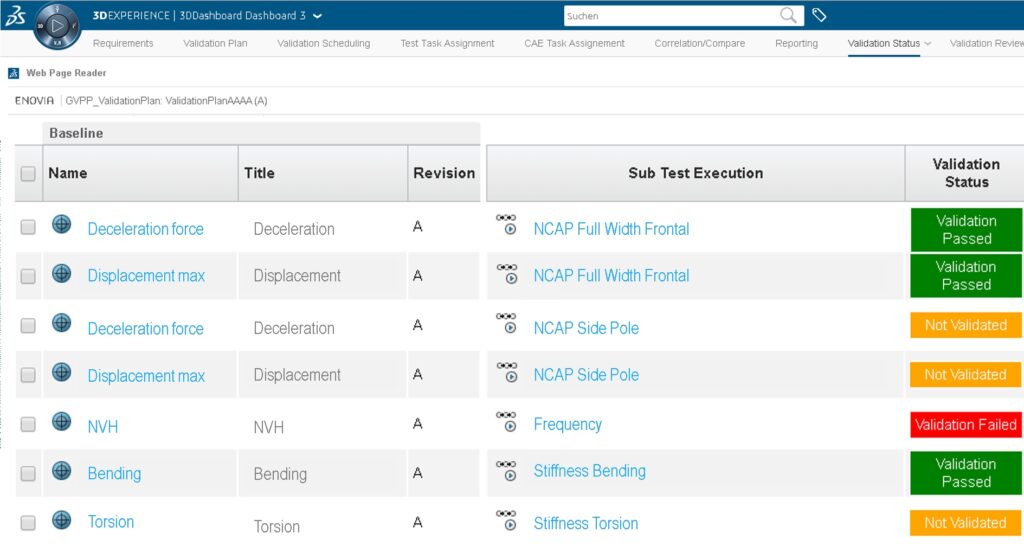

Ultimately, one of the main reasons organizations use simulation is to predict product performance against requirements. Physical testing is either more expensive or more time-consuming or both. As vehicle complexity increases, so do internal, consumer, and regulatory requirements. For example, the schematic below illustrates the substantial growth in requirements for crashes over the last 50 years.

The 3DEXPERIENCE platform can manage the feedback loop between requirements and validations through simulation or physical testing. The ability to aggregate all of this information in one place continuously throughout development offers the possibility to make better design decisions faster.

The other main reason for simulation is to gain insight into product behavior and performance early in development. By using simulation to explore design alternatives, you can quickly discard poor designs and focus on the most promising. This is why tools for rapid design exploration are integral to the 3DEXPERIENCE platform.

Today, NVH, durability, and crash teams do not collaborate until formal design reviews. With all their data unified on the 3DEXPEREINCE platform, they can share different design proposals and countermeasures continuously. This way, each group can stay on the same page and CAE teams do not have to wait until the next design gate to validate each other’s proposals from the previous release.

This cross-functional collaboration extends naturally to multidisciplinary optimization. In most OEMs today, true multi-disciplinary optimization is rare because of the data and organizational silos highlighted. Not only does the 3DEXPERIENCE platform facilitate unprecedented collaboration, it also provides a tightly integrated user experience for design exploration and optimization. You can optimize shape and size parameters, such as material properties and gauge thicknesses, directly as you define the simulation model. As below:

In conclusion, the historical way of working with multiple groups using multiple, disconnected tools cannot easily survive the next wave of innovation and competitive pressure. The 3DEXPERIENCE platform provides these key values to address the challenges:

- A single master model for design, simulation, and manufacturing

- Automated, CAD-associative simulation model building providing digital continuity to quickly address design changes and vehicle variants

- Integrated fastener and mesh management for different attribute simulations

- Collaborative engineering for design exploration and multi-disciplinary optimization

- Requirements-driven simulation via dashboards

As companies invest more in vehicle electrification and autonomous driving, crash, durability and NVH, departments need to be more productive with fewer resources. While excellent structural performance is necessary, it is no longer sufficient. The challenge now is to achieve superior performance and compliance for all structural attributes with minimal cost. DS is investing along with our customers to support these critical transformations.

See all our Transportation & Mobility solutions by visiting: https://www.3ds.com/products-services/simulia/trends/modsim

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW, and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.