Tire Engineering Solution

Like many other people around the world, I take a lot of pride in my car. My first car, a prized possession, added a lot of value to my life. Whether it be a daily commute to the office, family vacations, or long, leisurely drives, my car keeps up with me through the ups and downs of life. But what keeps the car going? Is it the luxurious cabin? The ride and handling characteristics? All these are true, however; the tire is also a very essential component to keeping my car going through the journey of life.

Day-by-day, fuel prices are rising around the world and international regulations on CO2 emissions are becoming more stringent. In 2015, 135 grams of CO2 per kilometer was the permissible limit of the vehicle. The target value by 2020 is 95 grams per kilometer. Therefore, automobile manufacturers need to figure out how to improve the vehicle performance but also increasing the fuel economy. And SIMULIA can help!

Aerodynamic drag is one of the biggest contributors to the fuel economy of a car. The higher the drag, the lower the fuel economy or range in terms of electric vehicles. So what is aerodynamic drag? Why is it so important to study the drag in the early stages of design?

Aerodynamic drag is the air resistance on the moving vehicle. Drag is mainly affected by three parameters of the vehicle: shape, size and speed. Every part of the vehicle contributes to the total drag, including the wheels and tires.

So why do we neglect the tires when they play such a crucial role? Did you know that the wheels can contribute to almost 25% of the total aerodynamic drag of a vehicle? A tire with better aerodynamic properties will not only consume less fuel, but will also have better acceleration capabilities, higher maximum speed, and increased driving range. Despite all of these advantages, so far tire designers have mostly thought about structural rigidity, rolling resistance and durability and have not done due diligence when it comes to the aerodynamic aspects.

Let’s now walk through the steps of designing a tire with improved aerodynamics:

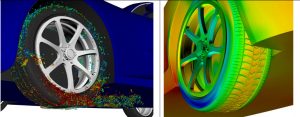

- Start with a ribbed tire in deformed position – you will get this as output of the footprint analysis performed using our simulation tools. This gives the realistic shape of the tire under deformation due to the weight of the car.

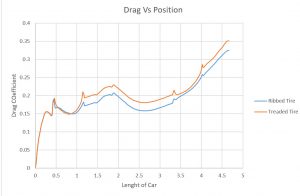

- Then, simulate the ribbed tire for a 100 kmph speed using the ready-to-use template and plot the surface drag on the car with respect to position. Using the template reduces the setup for simulation from hours to just a few minutes. This way, we can calculate the drag as per the requirements from the WLTP regulations for CO2 emission.

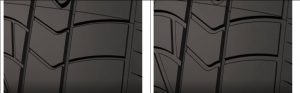

- However, as a caution while working on the above step, one can lose the drag details because of the tread pattern, therefore, at SIMULIA we provide capability for simulating a treaded tire to capture the details of tread pattern variation.

- From the above figure, we can see that the ribbed tire, which is qualifying for WLTP regulation, actually underestimates the drag on tire versus the actual treaded tire.

- The tire model that we have created is a parametric model. This allows to varying the tread patterns in CATIA and simulate them as well. We changed the tread pattern by changing the tread block height and width between the treads and calculated the drag forces for various configuration of tread patterns.

- Our observation was that by simply changing the tread height and width between the tread blocks, the drag on the tires can be reduced by 2%, which leads to an increase in the fuel economy of the car.

In addition, this simulation of realistic tread gives confidence to tire manufacturers to design robust and fuel economic tires.

From the above demonstration, SIMULIA provides an excellent way to predict the drag of a tire using PowerFLOW’s computational fluid dynamics in the early design phase. One can analyze the aerodynamic drag of different tire configurations for the same vehicle. In addition, one can improve the tire performance by changing the tread patterns of the tires. This solution can facilitate not only tire manufacturers but also the automobile manufacturers to find the best suitable and most effective tire model for the car.

So sit back and enjoy the ride!

For more information, email: Ketan.GHOTKAR@3ds.com, Jonathan.Jilesen@3ds.com

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW and more. The SIMULIA Learning Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Learning Community provides you with the tools you need to expand your knowledge, whenever and wherever.