Companies in all sectors are defining and deploying joint business/IT digital transformation to enable a more flexible and focused business infrastructure. This, in turn, helps to drive new business models and achieve improvements in traditional areas of:

- Revenues

- Margins

- Quality

- Time to market

and further help to

- Monetize aftermarket services

- Monetize end-user experience

- Increase visibility and traceability of resources (people, material, suppliers, customers)

We are seeing a tremendous push for new thinking, new technologies, new solutions, and new standards. The reaction by the industry is to push their IT software and services partners into Industry 4.0, IIOT, IOT, Digital Threads, Digital Twins, and Data Science domains.

Digital Twin realization through Digital Thread forms the core of the Digital Transformation initiatives. The overall market size of Digital Twins is estimated to be $16 Billion by 2023 (Source: Grand View Research). Amongst all the use cases of Digital Transformation and Industry 4.0, Advanced Digital Product Engineering is estimated to be the biggest use case with a 20% CAGR (Source: Industry 4.0 and Smart Manufacturing 2018-2023 report).

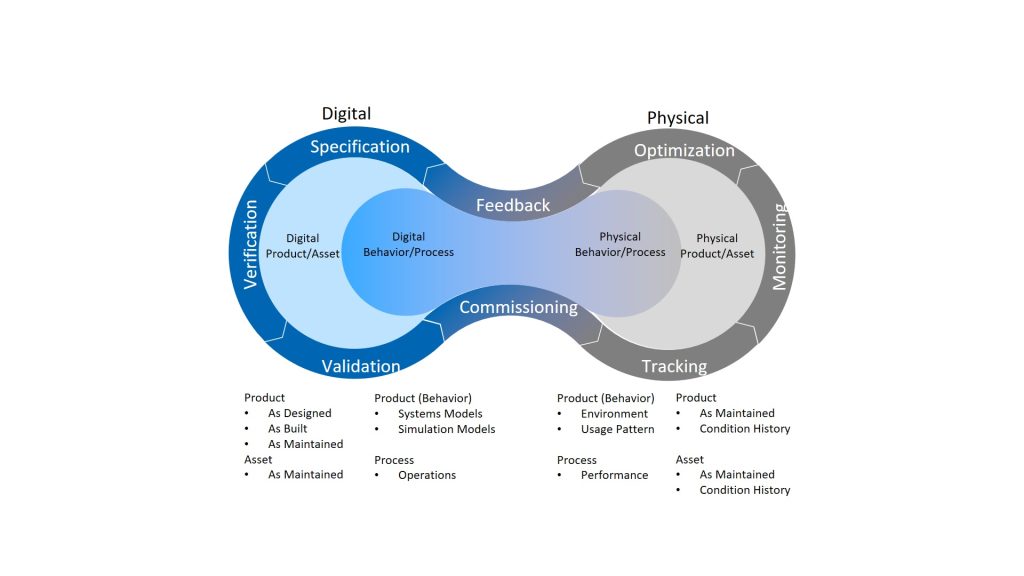

Gartner defines Digital Twin as an evolving Digital profile of the historical and current behavior of a physical object or process that helps optimize business performance. Hence, one can realize the Digital Twins of

- Product Twin – Connected to the physical product in the field

- Asset Twin – Connected to the physical asset on the plant floor

- Process Twin – Connected to actual deployed process in operations

The true value is derived from the interconnection of the twins that is capable of

- Monitoring the operations and behavior of actual deployed products, assets, and processes

- Predicting the modes of failure from the operations data acquired and the model behaviors

- Prescribing the corrective actions and application to future knowledge, standards, and rules to improve the subsequent products/assets/processes deployment

The Digital Thread then forms the mechanism containing all the necessary information to generate and provide updates to multiple Product/Asset/Process Digital Twins. Hence it is the foundation for realizing the Digital Twins.

Unfortunately, the traditional deployment methodologies of IT applications and solutions are not capable of addressing the needs for the Digital Threads and Twins. As our customers have continued to invest in multiple generations of authoring applications, they have seen their digital asset investments failing to realize the full value of synthesizing data to information to knowledge. Their digital assets have been overly constrained and not able to achieve the proper levels of visibility, context, and latency required by their business processes.

Software companies have taken steps to overcome these constraints by:

- Acquiring new companies and solutions to provide end to end coverage of authoring and consumption domains

- Re-engineering the platforms to provide a unified model capable of managing the requirements, engineering, build, service, operate and validation models

- Developing point to point, hub-based, ESB based integrations between applications

Dassault Systèmes with its 3DEXPERIENCE platform provides the capability for the realization of Digital Twins. With the paradigm shift in 3DEXPERIENCE of moving away from working with documents to working with data, traceability between attributes & data elements can be implemented. With CATIA Systems, Cameo, Dymola, and Simulia, R-F-L-P models can be created and validated through behavioral simulations. The strategy of unified product structure at the core will establish the product thread. These functional capabilities of the 3DEXPERIENCE platform can be coupled with external technologies to obtain real-time data from the products/assets/processes and create Digital Twins on the 3DEXPERIENCE platform.

In our view, while these tools and platforms provide the ability to realize the Digital Twins, customers will continuously need to manage the following challenges towards homogenizing the application landscape:

- Best of the breed applications will continue to exist in the respective domains of engineering, manufacturing, aftermarket services, and product operations

- Lack of a global standard capable of defining the comprehensive unified information model for the digital thread across domains of engineering, manufacturing, aftermarket, and product operations

- Change management and cultural alignment required for transformation to one single platform

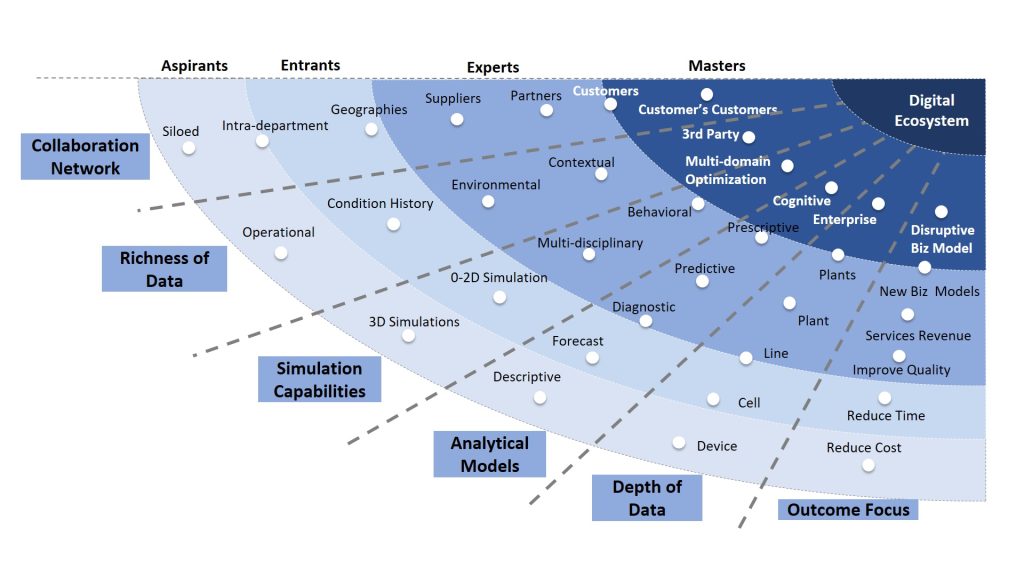

Hence, at HCL, we believe every organization will need to engineer its path through for this Digital Transformation and Digital Twins realization by picking the right elements at relevant maturity level targets as shown in the figure below.

HCL’s Product Lifecycle consulting has worked with its customers to identify and define this roadmap unique for each customer depending on the existing maturity level of the customer.