Why private 5G networks are the next big breakthrough for IIoT

5G – the fifth generation of mobile communication standards – has already begun to roll out worldwide. In fact, some of you will probably be reading this post over a public 5G cellular connection. However, there is another application for 5G which analysts expect will grow to become a major market by the 2030s: private 5G networks for the Industrial Internet of Things (IIoT).

Private industrial wireless networks allow significantly more flexibility than wired networks and better security and reliability than public networks. The facility can be changed without having to re-cable the network – this is crucial for unlocking the full potential of the “smart factory” concept where the assembly line can be automatically reconfigured to manufacture different products with minimal downtime. Private 5G networks will also be necessary for facilities such as mines and ports that are located distant from the urban areas where public cellular networks proliferate.

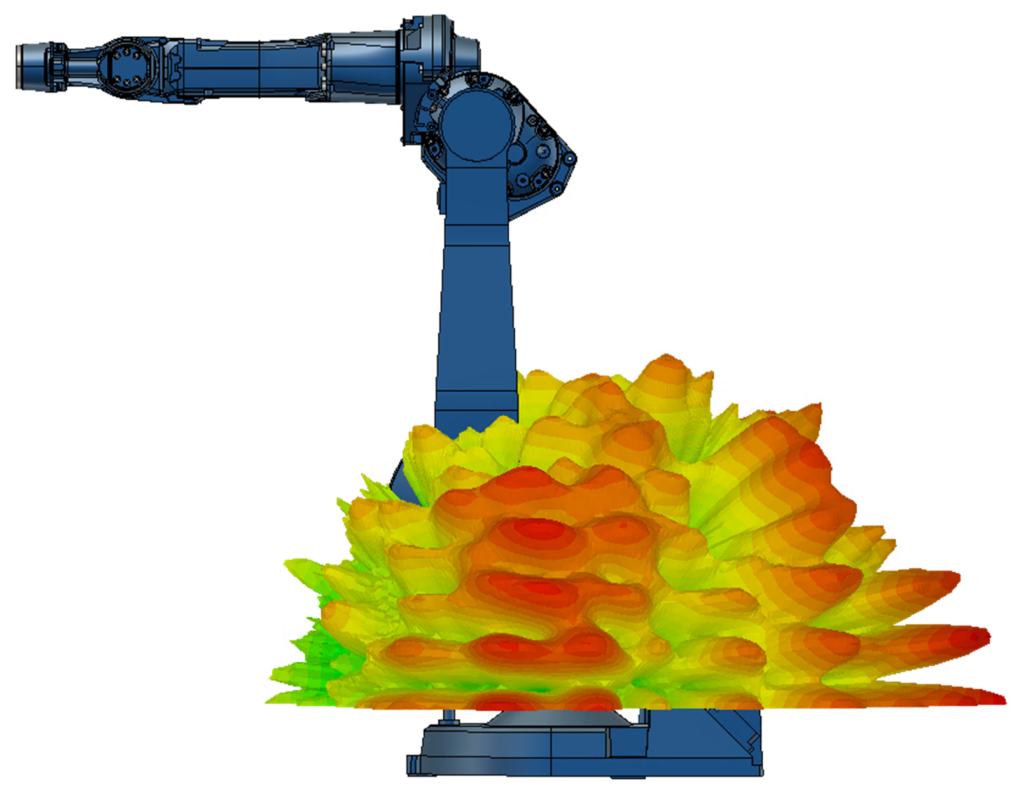

Previous attempts to use wireless protocols such as 4G/LTE and WiFi in the industrial internet of things (IIoT) applications have suffered from some limitations of these technologies. Mission critical machinery – such as a robot arm on an assembly line or an autonomous guided robot (AGV)– need a highly reliable connection with near-instant response times, and enough bandwidth to transmit data such as telemetry and high-definition video. Critically, high quality connections must be maintained even under dynamic conditions where an AGV is traveling across a manufacturing floor for example. WiFi, in particular, can struggle to maintain a connection in this scenario. 5G offers much higher data rates, lower latency and better dynamic connection support compared to previous wireless protocols, meaning it has the potential to replace wired networks in large facilities such as manufacturing halls and warehouses.

Challenges of private 5G network design

Any downtime is expensive in manufacturing, and it can be safety critical in some types of facilities (for example, warehouses, power stations, airports and hospitals). Industrial networks therefore require far stricter standards of coverage and reliability than consumer-grade networks can tolerate.

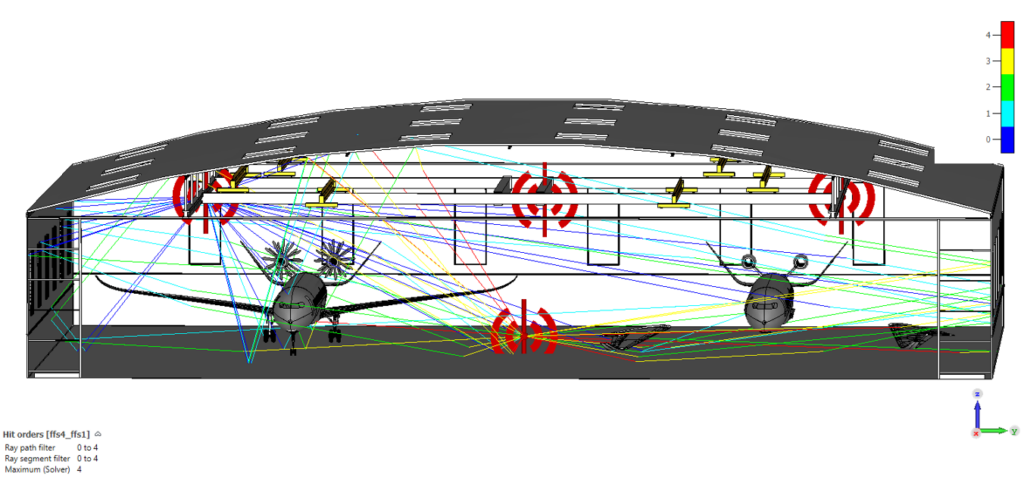

Assuring coverage for 5G networks can be challenging – particularly for the millimeter wave (mm-wave) bands, where wavelengths are so short that walls become obstacles, and reflection causes complex multipath propagation. Most private 5G networks will cover facilities that are indoors, meaning that networks will have to be very carefully designed to ensure coverage and connection quality.

This is made more challenging because these environments are often full of metal machinery, vehicles, containers and other movable structures. A private 5G network needs to be agile enough to operate under any expected configuration of the space.

Simulation unlocks the power of 5G for industry

Dassault Systèmes offers a solution to facilitate the planning of agile private 5G networks. It not only allows manufacturers and other stakeholders to design optimal 5G access points – the electromagnetic simulation technology from the industry-leading SIMULIA software CST Studio Suite, also calculates the propagation of electromagnetic fields through complex 3D environments. The full wave behavior can be modeled, including reflections and diffraction, to capture multiple-input multiple-output (MIMO) and multi-path propagation. The channel impulse response can be calculated to determine the connection’s quality.

By interfacing with the operational planning and simulation tools and the CAD tools from the DELMIA and CATIA brands of Dassault Systèmes respectively, network planners can consider how propagation and coverage is affected as machinery moves and spaces are reconfigured. For example, in an aircraft hangar, simulation will show not only whether there are areas of poor reception in the shadow of the aircraft, but also how these shadows change as aircraft or AGVs move within the space. In a smart factory, simulation shows 5G propagation and coverage for different assembly line configurations.

Leveraging simulation in the network design process accelerates the rollout of a private 5G network, saving both time and money. Simulation helps engineers ensure reliability across possible scenarios, reducing downtime as well as ensuring sustainable networks by deploying the optimal number of access points.

In a crowded electromagnetic environment, co-site interference and electromagnetic compatibility (EMC) are serious concerns. EMC simulation identifies potential interference issues early in the development process, reducing the risk of expensive fixes needed after installation. The exposure of workers to RF fields can also be analyzed, in order to ensure that safety limits on RF radiation exposure are not exceeded.

Private 5G networks typically involve close cooperation between several major stakeholders, including equipment manufacturers, network designers/operators, and the end user. The requirements and input from all these stakeholders are brought together with collaborative design and simulation on the 3DEXPERIENCE platform. This breaks down silos and enables faster design iterations, while also protecting confidential intellectual property such as antenna designs.

Key takeaways

5G offers higher bandwidth, lower latency and better dynamic performance than previous wireless protocols. Private 5G networks will unlock the potential of IIoT by allowing thousands of connected devices to operate close together and will enable facilities to become more agile, more efficient and more reliable.

Many industrial sites are challenging environments for 5G networks. Moving machinery and smart assembly lines mean that many different equipment configurations may need to be assessed to be sure the network performs in all scenarios.

Simulation can assess signal propagation and coverage before committing to installation. Areas with poor signal can be identified and corrected, avoiding potential communication issues and downtime. Using simulation to develop private 5G networks can save both time and money, and reduces deployment risk.

Join a community of simulation enthusiasts focused on advancing the use of SIMULIA simulation solutions in science and engineering! It’s free and easy. Start a discussion with other members of the SIMULIA Community. Talk through your simulation questions with peers, SIMULIA experts, and SIMULIA Champions. Apply to be an author to create posts, share useful tips you discovered for SIMULIA software, and establish yourself as a thought-leader. The SIMULIA Community is home to both SIMULIA product users and SIMULIA subject matter experts around the world.