This is Part 2 of our 6-part blog series based on the Frost & Sullivan white paper, “Inspiring Manufacturing Transformation in the Digital Era.”

Critical Manufacturing Issues

Frost & Sullivan has identified four critical manufacturing industry issues that occur during the transformation journey:

- Collaborative manufacturing landscape

- Digital supply chain

- Changing business models

- Workforce of the Future

Understanding the areas where critical issues occur can help manufacturers align internal practices and processes as they start their journey toward a factory of the future.

Critical Issue #1: Collaborative manufacturing landscape

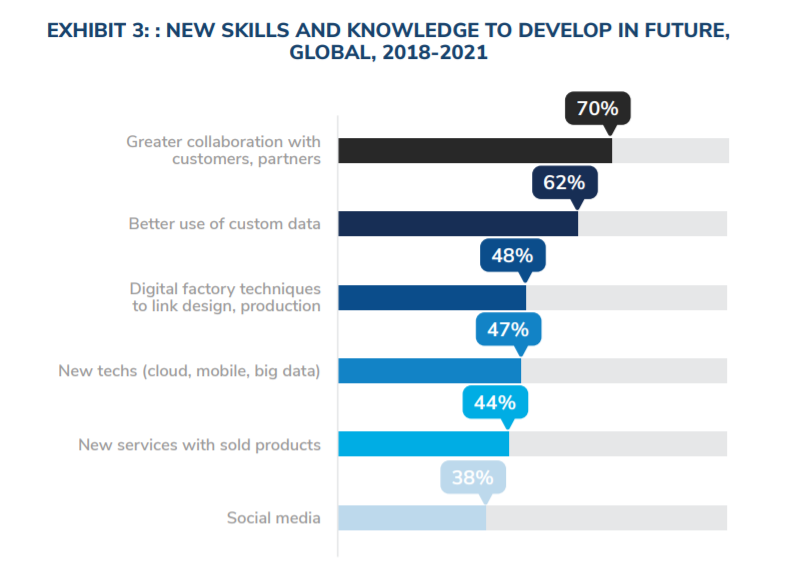

Manufacturers realize the value of actively transforming site-functional silos to more cross-functional operations across their enterprise. This will require new collaborative processes and architectural transformations to achieve excellence in integrated business operations. New data flow of information is required to connect all functions and multiple areas of expertise, which will drive awareness, growth and competitive success. Ubiquitous connectivity will steer the shift from reliance on mechanical aptitude to data-driven decision making. The process of transformation is becoming more collaborative among humans, machines, processes, and data. According to a recent Frost & Sullivan survey, as shown in Exhibit 3, the majority of participants will be focused on collaborative organizational models with customers and partners to develop knowledge.

Critical Issue #2: Digital supply chain

The manufacturing experience is also expected to move from the use of linear supply chain operations to more digital, connected, and end-to-end manufacturing value networks. Factories of the future will operate in a microcosm of global and regional networks to achieve enterprise-wide scalability. The manufacturing experience is also expected to move from linear supply chain operations to more digital, connected and end-to-end manufacturing value networks. This is the emergence of a digital supply chain. With the emergence of the digital supply chain, both inbound and outbound logistics are expected to transform and be available on demand by nature. Digital supply chains of the future will play an important role within the integrated digital ecosystem and form a symbiotic interaction between suppliers, logistics providers, people and intelligent machines/systems.

By leveraging the data to create a model of the physical operational world, companies can have a digital twin for their operations and factories. The result is a model that virtually optimizes, simulates, and tests scenarios to maximize the physical operational network. The industry is in a state of change with an increasing need to have an end-to-end view of operations, faster and more informed decision support, and the flexibility to support new customer requirements

Critical Issue #3: Changing business models

IIoT, Big Data, mobility, and AI technologies are altering industry structures and transforming traditional business models through applications such as predictive equipment performance management, energy cost reduction, responsive quality, and full forward and backward value chain traceability.

Critical Issue #4: Workforce of the Future

The ability to work comprehensively with a wide range of technology competencies across the manufacturing enterprise is of paramount importance. Frost & Sullivan has identified 13 important digital technologies to drive the transformation journey. These technologies will help companies attract and empower new workers through the creation of engaging and interactive work experiences

[Download the full Frost & Sullivan white paper to read more about Critical Issues #3 and #4]

Part 1: Executive Summary

Part 2: Critical Manufacturing Issues

Part 3: Where Is the Business Value for Customers?

Part 4: Dassault Systèmes Smart Manufacturing and the Factory of the Future

Part 5: Dassault Systèmes 3DEXPERIENCE Operations Value Network

Part 6: Customer Benefits and Outcomes

Download the Frost & Sullivan white paper

Join our User Communities to stay on top of the latest industry news, ask questions and collaborate with peers:

- EXALEAD Sourcing & Standardization Intelligence User Community

- 3DEXPERIENCE Marketplace | PartSupply User Community

- NETVIBES Public Community