Challenge

The company is a leading multinational producer of luxury automobiles and sport utility vehicles (SUVs). Its mission is to become an all-electric luxury brand by 2025, and to establish itself as the world leader in electric SUVs and services. To accomplish that, the company needs end-to-end visibility, accountability and transparency. But silos of information, created by multiple systems and point solutions, were making that impossible to achieve.

Solution

The company launched its business transformation strategy to overcome these challenges. Based on its positive experience with Dassault Systèmes NETVIBES and other solutions, it chose the 3DEXPERIENCE© platform to bring all its data together and provide a foundation for its transformation. The NETVIBES Sourcing & Standardization Intelligence portfolio is deployed on the platform as part of the Global Modular Architecture solution, providing out-of-the-box capabilities to meet the company’s goals.

Benefits

The artificial intelligence-driven Sourcing & Standardization Intelligence solutions have empowered the company to standardize its components catalog, facilitating streamlined product design, easy identification of opportunities for part reuse and cost take-out, and competitive sourcing of components. Available on the 3DEXPERIENCE platform, they allow unprecedented collaboration across design, engineering and purchasing teams. These benefits have also helped to optimize the supply chain, making it easier for the company and its suppliers to do business together.

A driving ambition

The company, a leading multinational producer of luxury vehicles and SUVs, is positioning itself to take the lead in a rapidly changing global automotive industry. Its mission is to become an all-electric luxury brand by 2025, and to establish itself as the world leader in electric SUVs and services. To facilitate that, it must simplify everything it does.

“Our vehicles contain some of the most remarkable engineering feats in the automotive engineering sector, and that’s all hidden behind the simplicity of our design,” said the company’s head of Procurement. “As we accelerate our electric vehicles and increase the levels of technology in them, it’s vital that we can simplify how we operate internally. We need to operate faster, leaner, smarter and to enable rapid realization of becoming a modern luxury brand. But we also need to ensure the long-term sustainability of our business. This means we need tools to help us deliver on time, on quality, on cost, as well as delivering value to our customers and optimizing value to our company, our supply chain and how we do business together.”

End-to-end visibility, accountability and transparency are essential to the company’s goal. But like many large enterprises, it was working with multiple IT systems and point solutions which created silos of information. This disparate landscape made it impossible to establish the continuity and visibility it needed. Control models were managed manually and in varying ways across the organization. The bill of materials was unwieldy, with no simple way to identify changes to parts. And as the company’s vehicles grew more technologically complex, managing software and updates was increasingly difficult. All of this, along with global supply chain issues, was hampering the ability to deliver new vehicles on time and on target, with significant impacts on different functions downstream.

The company launched its business transformation strategy in 2021 to overcome these challenges and achieve its goals. It had already partnered with Dassault Systèmes to deploy NETVIBES solutions that removed the need for spreadsheet-based reporting and provided real-time dashboards for project management. Impressed with what it had seen, it chose the 3DEXPERIENCE platform to support its transformation, with solutions from NETVIBES to provide the key functionalities it needs.

Mastering complexity through collaboration

By bringing enterprise data together in one place, the 3DEXPERIENCE platform breaks down the information silos that exist across large organizations. Different roles can collaborate, even if they traditionally work in separate systems. The platform is the foundation for the company’s transformation.

NETVIBES Sourcing & Standardization Intelligence is deployed on the platform as part of Dassault Systèmes’ Global Modular Architecture solution. The result is a set of solutions and processes that work together seamlessly to drive end-to-end vehicle development. It gives the company the connected insights and agility it needs to balance the complex demands of stakeholders across the product development process and efficiently meet customer expectations. The platform also makes it easier for people to work together across the supply chain, integrating operations with partners and suppliers.

This approach takes the company beyond traditional product data management, bringing an enterprise systems-engineering approach that encompasses everything from the bill of materials to digital mock-up and vehicle architecture validation. NETVIBES plays a key role by providing standard component management, sourcing, collaborative planning, execution and analytics, product costing and cost intelligence.

“As the de facto source for all our engineering data, the 3DEXPERIENCE platform doesn’t just help bring people together,” explained the head of Procurement. “It also helps create historical traceability and breaks down silos to support collaboration across the enterprise. For instance, with Sourcing & Standardization Intelligence, buyers are no longer sourcing a part number. They can see the part in front of them and they’re collaborating with their engineering, quality and supply chain counterparts, linked to the actual product they are looking to source.”

Streamlined product design

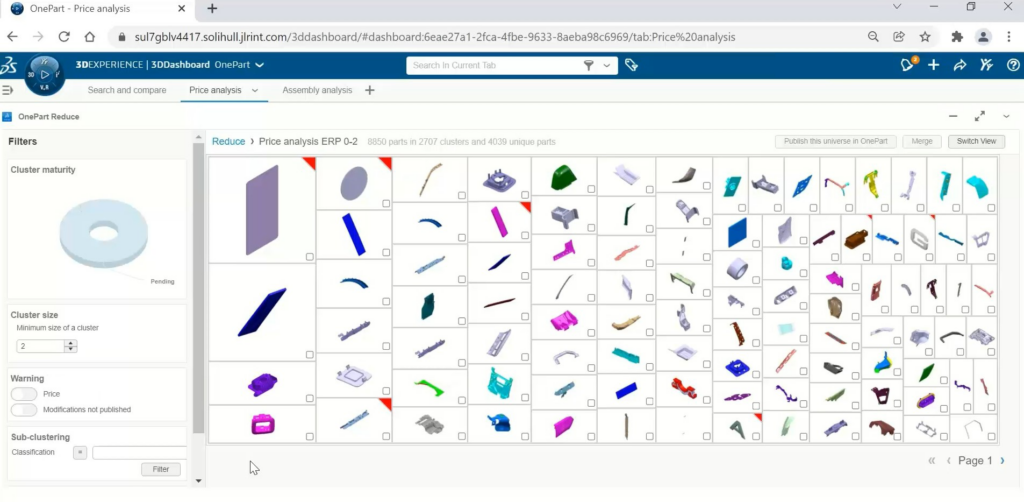

With increasing vehicle personalization, Sourcing & Standardization Intelligence provides an intuitive way for the company to standardize components across different product lines and variants. The solution uses artificial intelligence and machine learning to identify similar parts based on their 3D signatures and metadata, then applies an algorithm to automatically generate clusters of parts. The result is a searchable catalog of master components and alternatives – and more efficient product design.

It takes just a couple of clicks to search the catalog and compare different parts according to metadata attributes such as geometry, material, cost or supplier. And once the 3D part is found, it can be downloaded and tested directly in the assembly.

“The ability to compare the 3D parts by geometry and metadata is transformational,” said the head of Procurement. “When engineers are designing a new vehicle, they’ve got a rapid means to identify similar parts, which can inform their design activity. Just being able to see that data in one place is huge.”

AI clusters parts by 3D similarity to identify cost savings

Creating economies of scale

Sourcing & Standardization Intelligence enhanced ‘search and compare’ capabilities also help users to drive the reuse of parts and find cost take-out opportunities. The solution provides a comprehensive ecosystem of parts and suppliers with simple, 3D visualization of each part so any stakeholder knows exactly what they’re looking at. Alongside this, an overview of the most recent purchase orders yields relevant pricing and supplier knowledge, with quick access to similar parts.

Designers, purchasers and managers can view clusters of similar parts based on their 3D similarities, complete with warnings to alert them to any price inconsistencies. To investigate further, they can view all the metadata around the parts and compare similar parts within a specific cluster. This allows them to identify cost savings opportunities and apply standardization across vehicle programs – all within a couple of clicks.

“Driving the reuse of our parts across multiple vehicles has lots of economies of scale for us,” said the head of Procurement. “The ability to do so very early on in our processes, even during the concept phase, helps us deliver on cost, efficiency and time to market.”

Speeding supply chain optimization

By powering up parts standardization and reuse, Sourcing & Standardization Intelligence also makes it easier for the company and its suppliers to do business together. The ability to search by 3D similarity, combined with the capacity to add data from partners and suppliers, makes the purchasing team’s job much easier and extends benefits across the supply chain. The result is better visibility and richer relationships with suppliers.

“The ‘reduce’ element helps us work cross-functionally to drive optimization within our supply chain,” explained the head of Procurement. “For example, some of our suppliers might make several different parts that are just slightly different, and we have as many different purchase orders. Reducing that number streamlines that supplier’s long-term manufacturing planning software and their supply chain.”

Our goal is to change our operational model and transform from transactional, status-driven reporting to risk-managed and risk-based decision-making with end-to-end visibility, accountability and transparency. The 3DEXPERIENCE platform provides us with a strong foundation to deliver this transformation.

Head of Procurement

Accelerating competitive advantage

A comprehensive, searchable and visible overview of components also helps the company to be more competitive when it comes to sourcing the parts it needs.

“Computer-aided design data, enriched with metadata, purchasing data, capacity data and quality data from the supply base, helps us to make sure we are more informed within the organization,” said the head of Procurement. “It also helps us to gain competitive advantage when working with suppliers because we know what we want and what our baseline is. We’ve got ideas about what components should cost, but we also know what our actuals are and we have all that information in one place. We know which parts we can reuse, but just as importantly, we know when our supply chain doesn’t have the appropriate capacity to do that. Just knowing that and being able to scenario-plan around it is absolutely transformational.”

Sourcing & Standardization Intelligence has already delivered significant benefits for the company in terms of parts standardization and supply chain optimization. But this is just one piece of the bigger picture. As it continues its business transformation, the 3DEXPERIENCE platform brings powerful ways to connect the extended enterprise.

Morgan Zimmermann, CEO of Dassault Systèmes NETVIBES

An end-to-end vision

“Powered by NETVIBES data science, Sourcing & Standardization Intelligence has already delivered significant benefits for the company in terms of parts standardization and supply chain planning and optimization. But this is just one piece of the bigger picture,” said Morgan Zimmermann, CEO of NETVIBES. “As it continues its business transformation, the 3DEXPERIENCE platform brings new ways to connect the extended enterprise.”

“Our goal is to change our operational model and transform from transactional, status-driven reporting to risk-managed and risk-based decision-making with end-to-end visibility, accountability and transparency,” said the head of Procurement. “The 3DEXPERIENCE platform provides us with a strong foundation to deliver this transformation. It gives us a single source of high-quality data, and it breaks down the silos between all the different functions. In doing so, it becomes much more than an engineering tool. By joining up multiple capabilities using data science we can create a lot of value for the business.”

Download the eBook to discover more NETVIBES data science solutions in action!