Automotive manufacturing has seen rapid change over the past several years. With developments in electrification and autonomy, expanded functionality and new features being introduced, manufacturers are pressed to adapt and make their own transformational changes swiftly. Keeping up with such innovations is a challenge in itself — not to mention the need to balance managing industry growth and capturing market share, which means being first to market, delivering high-quality and low-cost products to customers.

Addressing these priorities requires efficient, cost-effective operations. And just like the vehicles you manufacture, you need your operational teams to run like a well-oiled machine. However, automotive teams today are pressured by complex operations while working within so many requirements and constraints. This can easily lead to miscommunication, missed key objectives and poor engagement from team members.

Productivity cannot be assumed, but it can be nurtured. Here, we explore the key business trends that are affecting operational efficiency in the Transportation & Mobility industry, as well as a collaborative solution that can empower your teams to be lean without limits.

Trends Driving Change in the Automotive Industry

Automotive teams face numerous challenges on a day-to-day basis, with these trends representing the driving force that is transforming the way teams work and collaborate.

- Increasing demand for new, innovative products and variants: Teams need to innovate in new and engaging ways, powered by well-planned yet agile operations and the required improvements, modification or adoption of new manufacturing processes to support it.

- Manufacturing with agility, quality and right first time: Teams must be engaged and focused on managing production, quality, material supply and operational teams with efficiency.

- Managing growth while maintaining market share: Teams play an important role in managing enterprise growth. This demands flexibility, agility, visibility and collaboration across the value network.

Addressing these trends will require automotive manufacturers to optimize operations for continuous improvement and effective lean programs. For this, it is key to raise the efficiency, visibility and agility of all teams—from strategic ideation down to tactical execution—regardless of whether the teams are all internal or part of a larger value network. To achieve all of this, organizations must create an environment and conditions that encourage workers to commit to shared objectives.

The Road to Digitally Lean Automotive Teams

Teams are the backbone of any organization. As such, you need to ensure they have the tools they need to ideate, collaborate and perform better to effectively meet business goals. This can be enabled leveraging a collaborative digital solution that can connect the dots between people, ideas and data—and is simple enough for everyone to use.

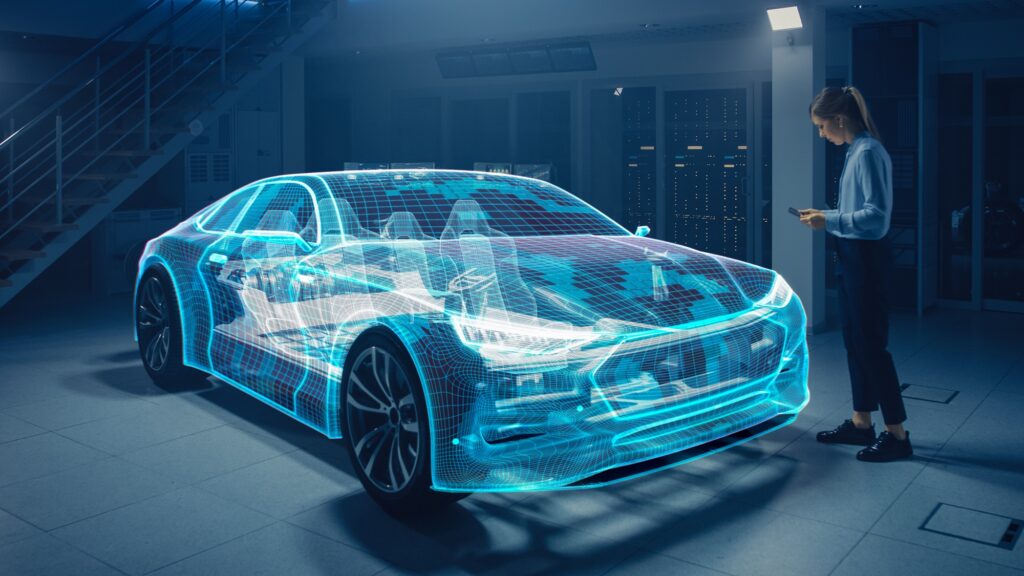

Powered by the 3DEXPERIENCE platform, DELMIA 3DLean is a customizable and interactive digital tool designed for operational teams anywhere, regardless of role. The solution leverages virtual universes to model and optimize resources and work processes before performing them in the real world, allowing teams to visualize 3D content and complex data with a digital lean framework. Whether teams are working across departments, on the shop floor or even remotely, 3DLean allows them to interact seamlessly. It enables team members to capture, monitor and track operational meetings and problem solving, providing the ability to aggregate relevant and key information from different areas of operations.

3DLean supports Transportation & Mobility teams through various challenges and goals to continuously improve operational efficiency, promoting lean principles in order to make “lean thinking” a standard part of business and company culture. With such a tool at your disposal, you can optimize team operations by encouraging impactful, efficient interactions between all workers and stakeholders in the enterprise to drive greater project success and innovation.

Learn more about how 3DLean can benefit your automotive manufacturing teams, and gain insight into its use via a customer case study, by downloading our eBook.