The European Spallation Source (ESS) is a massive research facility with a mission to become the most powerful neutron source in the world, accommodating various research activities. The facility faces significant challenges in managing a large-scale, one-off project, involving coordination with several institutes and sub-suppliers across 13 countries.

Magnus Tacklind and the European Spallation Source (ESS)

Magnus Tacklind, the manager of the engineering management group at the European Spallation Source (ESS), has a background in mechanical engineering and extensive experience in the nuclear industry in Sweden. ESS is a massive research facility with an estimated cost of €3 billion, involving a total of 13 countries. The facility operates as a spallation source, utilizing an accelerator to shoot protons into a target station, resulting in spallation to create a significant amount of neutrons for various research activities.

The mission of ESS is to serve as a powerful neutron source for a wide range of purposes, including research in different areas. The facility aims to become the most potent neutron source globally, offering substantial benefits for scientific research and development.

Challenges at European Spallation Source

The European Spallation Source (ESS) faces several significant challenges in the construction and operation of its research facility. One of the primary challenges is the unique nature of the facility. Building a one-of-a-kind research facility presents numerous hurdles, as it requires innovative solutions and careful planning to ensure its success.

Another major challenge involves managing work across several different institutes and subcontractors. With hundreds of partners involved in the engineering work, coordinating and consolidating efforts is a daunting task. The facility, spanning approximately 800 meters, demands high precision and narrow tolerances, with some components requiring tolerances down to the micrometer level.

We need to consolidate things, in a facility that is 800 meters long. We can see that CATIA actually has the strength of this whole range, from the micrometer level to the hundred meters facility. And to have all this in one tool is of course an enormous strength.– Magnus Tacklind, Group leader engineering manager, EUROPEAN SPALLATION SOURCE

Maximizing Efficiency and Collaboration with CATIA and 3DEXPERIENCE

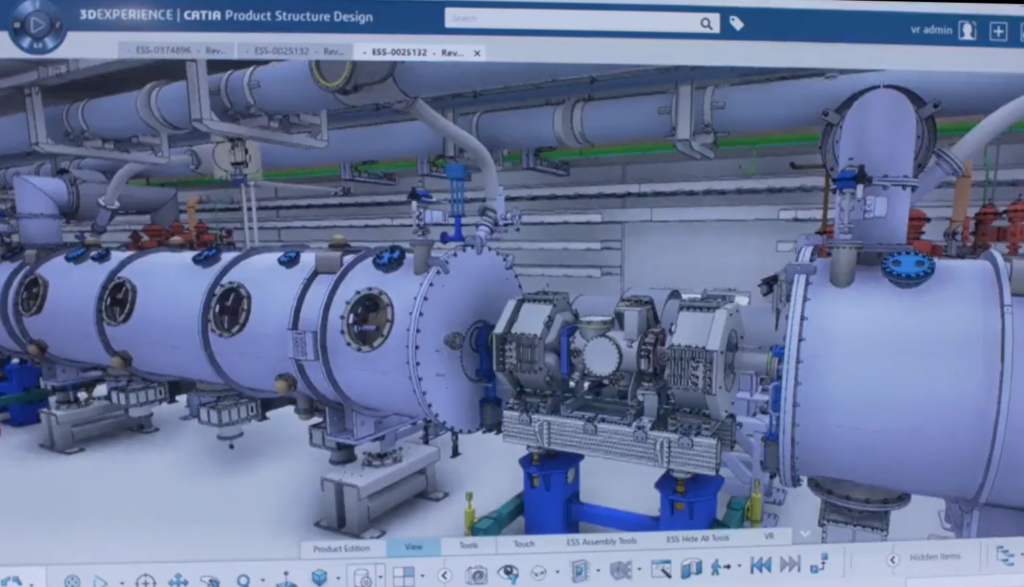

The European Spallation Source (ESS) utilizes the 3DEXPERIENCE as the central PLM platform, effectively consolidating all information within the organization. The 3DEXPERIENCE serves as the hub for the ESS plant layout, a massive CATIA model of the entire facility, integrating various physical models and data into one master model.

The integration of CATIA and 3DEXPERIENCE has proven to be a vital component in addressing the significant challenges faced by the ESS project. By leveraging these advanced tools, the project team can effectively manage the complexities associated with building and maintaining a cutting-edge research facility, ultimately contributing to the realization of ESS’s mission to become the most powerful neutron source in the world.

CATIA’s role in Product or Plant Lifecycle Management for the ESS project

CATIA, with its 3DEXPERIENCE, offers a myriad of benefits for the European Spallation Source (ESS) project. The platform excels in high-precision product design, allowing for the creation of components with micrometer-level tolerances.

The consolidation capability of CATIA has been a game-changer for the project. The platform serves as the central Product or Plant Lifecycle Management (PLM) system, consolidating all information and physical models of the entire facility into one master model.

Conclusion

In conclusion, the European Spallation Source (ESS) project faces significant challenges in managing a large-scale, one-off research facility, involving coordination with several institutes and sub-suppliers across 13 countries. Using the 3DEXPERIENCE platform for product and plant lifecycle management, along with the mechanical design capabilities of CATIA, has proven to be a vital component in addressing the challenges faced by the ESS project.

To watch this User Testimony and to discuss with thousands of CATIA experts, join the free online user community: go.3ds.com/catia