Background

Cultivated meat, plant-based protein, and fermented protein constitute a class of alternative proteins to replace traditional meat from productive livestock. This new trend in nutrition is causing controversy but also creates hope to address more fundamental challenges facing humanity today, such as hunger and poverty, climate change, health, and animal safety.

For fermented protein development, researchers design a precision fermentation process by isolating specific strains of bacteria or yeast. For optimizing the growth potential and nutritional characteristics, it is key to discover optimal conditions for processes including the bioreactor for growth of the specific target strain, purification, and finally formulating a product meeting the target requirements.

Plant-based protein design starts with a crop development phase wherein biologists investigate the crop genotype, and the functional identification and characterization of plant proteins, followed by breeding and cultivating the plants.

Plant-based proteins and fermented proteins are well-established meat alternatives on the market, whereas cultivated meat is still behind the curve, mainly because getting secure regulatory approval is more difficult. There are also complexities in R&D and in the cost of scaling up for production.

Since the first hamburger from cultivated meat was cooked and served in 2013, there has been feverish research to advance this field. Since 2020, about 300 scientific papers have been published dealing with this subject and many start-ups have been working in this area.

Discussion

Some of the most important parameters in cultivated meat development are nutrition, sustainability, and safety. For cultivated meat, the goal it is not only to produce aggregations of cells but more importantly to match the taste of traditional meat. Muscle tissue is a complex structure of cells that can’t easily be cultivated from a single specific dedicated cell strain.

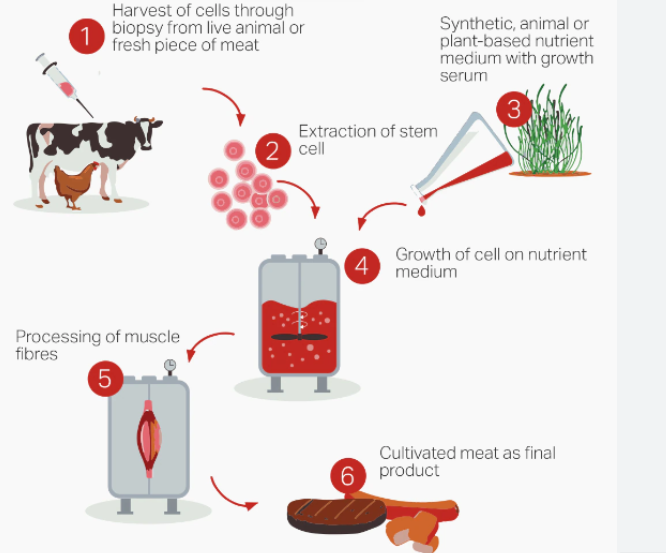

The cultivated meat development process has three aspects: a downstream phase, a phase to increase the biomass (myoblast), and an upstream phase. The upstream process consists of harvesting stem cells from an animal, proliferating them in a nutrient medium (composed of proteins, amino acids, hormones and other growth factors), and then pushing them to differentiate into muscle cells and attach to micro-supports or “scaffolds” to finally form clusters of cells or fibers.

As an example, to create the red meat of a hamburger, cells are fused to form fibers with multiple nuclei (called myotubes) to form muscle tissue. The myoblasts are placed in a gel that is spread around a tube, which results in the formation of rings of tissue. Contraction and relaxation of cells cause them to grow. As a last step, ~ 20,000 rings are carefully layered to create the meat. A major issue for the industrialization of cultivated meat is scaling up; this must be optimized in the future as reaching a large yield is a difficult challenge.

With BIOVIA applications, the full bioprocess is supported in the lab. Scientists document the steps from cell isolation and biomass expansion in the bioreactors to differentiation and purification of cells and the design of the bioreactor. During the monitoring of different parameters in the bioreactors, many types of sensors can be used and there is a clear need to directly connect data measurements from equipment to the experiment. Cell proliferation and differentiation phases produce a large quantity of raw data that can easily be captured with BIOVIA’s data acquisition system. This data is processed for visualization to show bioreactor conditions and process performance. With the BIOVIA portfolio of applications, we can provide improved monitoring of the data being captured and use our analytical tools to produce and compare different types of graphs for metabolite concentration, cell growth over time, and yield.

There is also an isolation and separation step to process the final food product. For this, the scientist has to make sure there are no toxic/unwanted process aid materials present in the product. Here, it could be helpful to use the BIOVIA Toxicity database and metabolite prediction tools to guarantee the safety and quality of the final product.

Conclusion

Several studies have shown that, although cultivated meat has a reduced direct carbon footprint, cultivated red meat has a higher energy consumption than chicken and pork farming. Consumer awareness is growing and cultivated meat should meet not only regulations, but also consumer tastes. During a Food Ingredient Europe event that I attended, a consumer test report was presented in which it was shown that cultivated meat is not readily accepted by the general public. Consumers are willing to feed their pets with cultivated meat, but they are not prepared to eat it themselves. Would a vegan eat cultivated meat? An important aspect to consider is also how cultivated meat can be assimilated into the world of gastronomy with its more rigorous taste standards. Would a traditional “Boeuf Bourguignon” with cultivated meat taste as good as a traditional one, cooked with a delicious piece of Charolais from Bourgogne? That is the real question!

Discover more about the advancements in biotechnology and the tools like BIOVIA ELN and LIMS shaping the future of alternative protein production.