All three realms of the metaverse − Consumer, Commercial, and Industrial − will trigger massive shifts in people’s social interactions and economic operations. The Industrial Metaverse − the “sector that mirrors and simulates real machines, factories, cities, transportation networks, and other highly complex systems”[1] − holds the most transformational potential for protecting the environment.

Technological Benefits of the Industrial Metaverse

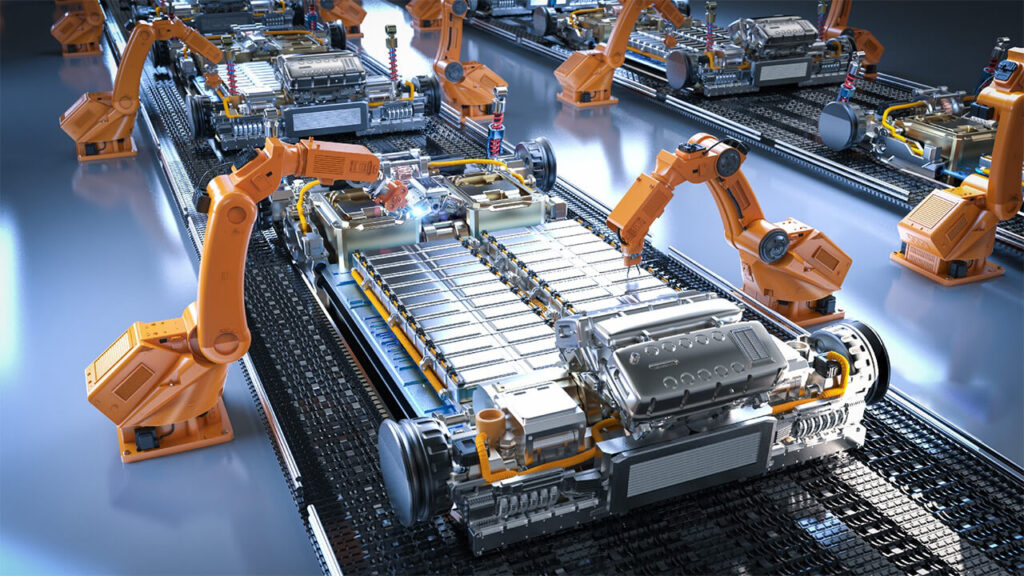

Fully immersive, photo-realistic, and physics-based, the industrial metaverse is heralding a new era in product design, engineering, testing, and operations. This paradigm extends beyond the product and into entire plants, processes, and systems. Industry 4.0, or the 4th Industrial Revolution, will connect current and future technologies, such as virtual twins, extended reality, cloud and edge computing, AI, machine learning, and 5G/ 6G. Collectively, they will enable real-time interaction among stakeholders and could optimize the use of time, energy, water, and other materials in manufacturing. The industrial metaverse could eventually eliminate travel and prototype costs and reduce products’ time to market.

The most humane overall goal behind this gigantic phenomenon is to digitally map solutions to complex real-world problems, such as environmental ones. There are other imaginable goals, and numerous consequences, of the industrial metaverse, whose advantages and disadvantages for humanity are up for debate. Data generation and treatment, privacy and security, IP protection, human behavioral changes, and the impact of massive data storage on the ecology are all aspects worth serious consideration and discussion.

Recycling Challenges

Let’s explore an environmental line of thought; resource optimization does not mean lower manufacturing and consumption levels overall, which would make the ultimate difference to the earth. Even if real-time collaboration, efficiency, constant product improvement, and process optimization are achieved in an immersive setting, they won’t stop over-production and consumerism. These aspects will likely exacerbate even more due to an expanding world population – expected to reach 10 billion by 2050.

In this context, a ray of light that could expose an environmental perspective to Industry 4.0, and corresponds to a real, pressing need is the possibility of employing resource optimization in the circular economy, specifically for recycling. Textiles, plastics, and metals, among others, could benefit.

Let’s take the examples of consumer electronics and automotive batteries. According to the United Nations, we generate approximately 75 million tons of e-waste globally, every year. Only 17% of the world’s electrical devices are disposed of properly or recycled. The fate of the vast remainder is unknown, except that Ghana, China, and India hold the world’s largest dumping grounds for e-waste.

In the automotive batteries market, 17.6 GWh of lithium-ion batteries reached end of life by 2021. This figure could grow to 140 GWh overall by 2035. In 2020 there were more than 100 GWh of lithium-ion batteries deployed in battery-electric (BEV) and plug-in hybrid electric (PHEV) vehicles.

So far, recycling in both areas is limited by technological and economic factors and, therefore, by insufficient recycling infrastructure. The recovery of metals from car batteries, such as nickel, cobalt, and lithium has been low – it requires unsustainable amounts of energy and chemicals. In the case of consumer electronics, a smartphone, for example, consists of over 50 different materials. All in small quantities, they are challenging to recycle in a pure-form in an economically sound way.

At the same time, the concentration of metals in nature has been decreasing. Lithium, for instance, is typically 3 to 4% of the composition of a rock today. Vast landscapes, entire ecosystems and related natural means of living for local people, are being destroyed to extract meaningful quantities. In addition, mining poses short-term risks for the water supply and the quality of the soils in corresponding areas, and long-term risks for local populations.

A Bridge between the Industrial Metaverse and Recycling

In light of these challenges in the recycling and raw materials sector, and the enormous capabilities the industrial metaverse can hold, it is only logical to aim at the industrial metaverse transforming recycling along multiple axes:

1. Above all, the collaboration and experimentation the industrial metaverse facilitates can result in product designs optimized for recycling in the first place.

2. As a next step, the virtual twin of each product would contain information about the types and quantities of its composing materials, which would additionally simplify its end-of-life treatment.

3. The industrial metaverse would also represent a safe and rewarding milieu for the development and testing of recycling methods, including an assessment of their economic and environmental implications, like energy, water, and chemical use.

4. Furthermore, the design, simulation, stress testing, and operation of recycling plants could be implemented digitally before it is realized physically. Global manufacturers are already using this opportunity for their plants in general: BMW with its iFactory and Equinor with its wind farms are among the lighthouse examples.

5. Recycling is also an area, where partnerships are crucial for all stakeholders along the value chain. The scale of collaboration, as well as the complexity and diversity of aspects partners can digitally cooperate upon are tremendous.

6. Last, but not least, recycling regulation is becoming increasingly important. In the EU, for instance, “new rules for the design, production, and waste management of all types of batteries sold in the [Union]” were approved by the European Parliament in 2023. [2] Legal obligations are hence another reason why it is worth seeking to develop the recycling industry’s potential through the industrial metaverse.

The Role of Dassault Systèmes

The role of Dassault Systèmes in this enterprise lies in the Virtual Twin Experience, processes, and systems we develop. Our strength is in the scientific and commercial character of our solutions connected to the original manufacturers’ source of information in real-time. With a primary focus and long experience in manufacturing and city infrastructures, the topic of recycling is inherent to our product portfolio vision.