By Guillaume Gerondeau, Vice President, Transportation & Mobility Industry Asia, Dassault Systèmes

Like the rest of the world, the Transportation & Mobility industry in ASEAN countries is undergoing a profound change as part of Industry 4.0. The increasing use of digital technologies, the growth of shared mobility services, and the rise of sustainable and electric vehicles are transforming the industry and presenting new challenges that must be addressed.

With the increasing automation, interoperability, and digitalization of manufacturing processes, supply chains, and business models, the transportation and mobility industry must consider how technology can best address current and future challenges. How can we ensure that technology is being leveraged to create tailored solutions that meet the evolving needs of the sector?

“Developing transportation solutions that are effective in meeting the industry’s needs requires not only addressing current challenges but also anticipating and preparing for future ones.”

Given the distinct characteristics of each organization and use case, it is crucial to create flexible and adaptable solutions that can cater to different contexts.

Organizational overhaul

As tech startups lead the way in developing new use cases for the transportation and mobility industry, traditional car manufacturers must adapt to the changing landscape and find new ways to contribute.

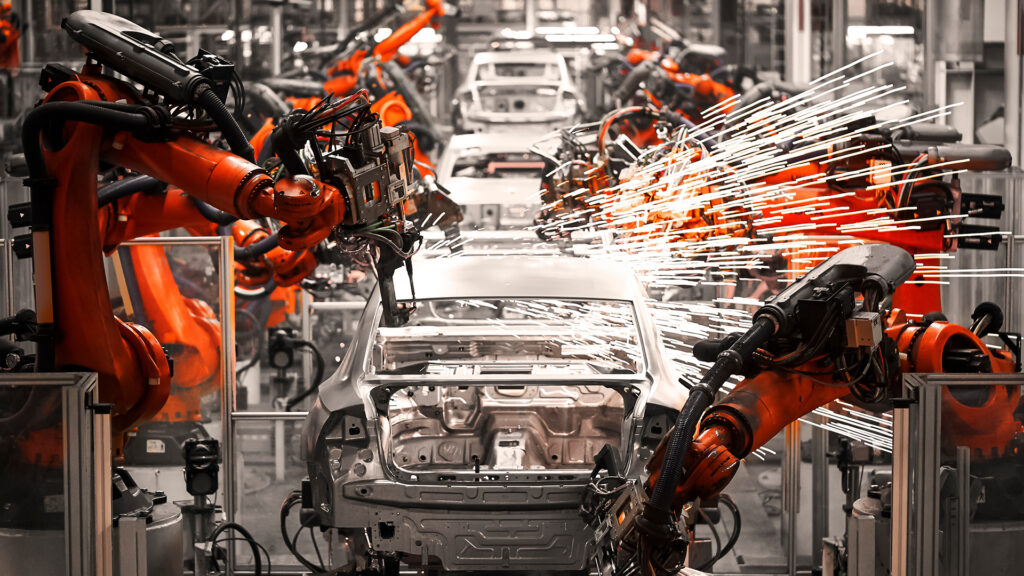

An organizational revamp is inevitable, especially with enterprises leveling up sustainable business practices. This involves not only an engineering effort, but also a collaborative business transformation where teams have access to creating a virtual twin of the product and entire processes of the enterprise through system engineering.

This allows for collaborative work and imagines new experiences, compared to the sequential approach of traditional product lifecycle management.

The processes of traditional car manufacturing are undergoing massive disruption. There are three challenges that car manufacturers will face in adapting to the changes:

- The first challenge is technological in nature.

- The second challenge is the ability to innovate. This allows for the exploration of various scenarios using virtual twins, resulting in faster testing of innovative solutions without the need to conduct real-world tests.

- The third challenge is evaluating the core business model of each player. Some may choose to divest and invest in new mobility businesses, while others may gradually improve their current operations. Each company will approach the revolution in their own way, but one thing is clear: they are under pressure from startups.

With global supply chains being the norm and component manufacturers spread out across different countries and often within different regions in large countries integration of systems can be difficult.

“Dassault Systèmes partners with several vehicle manufacturers for smoother and faster coordination between their sites.”

Understanding the market

Cross-border collaboration is also crucial when developing products such as smart automobiles and EVs. The market in each country is different; developing automobiles using one platform requires collaboration, and products also need to be customized for each customer segment.

For instance, an association of vehicle manufacturers in Indonesia aims to increase collaboration between local carmakers and their global counterparts. Of the 43 members in the industry group, three are already producing EVs.

The association acknowledges the need for pro-industry regulations for the auto manufacturing industry in Indonesia, and emphasizes the importance of educating the public about the practical differences between traditional cars and EVs. For example, the fact that EVs cannot be refueled in just a minute at a pumping station and driven for 300 kilometers.

“The challenge now is to accelerate development of EV infrastructure while lowering costs for consumers.”

The Indonesian market has unique characteristics, and the price differential between internal combustion engine (ICE) vehicles and EVs is still substantial. However, the sales of electric two-wheelers are expected to see growth in the next two years, as the price difference between electric and ICE motorcycles is not significant. Switching to electric motorcycles is a financially easier decision for people to make.

Nevertheless, car manufacturers must create products that cater to both the current mass market demand and also develop products that the market will need in the future, even if the demand is currently low.