Like many established businesses, DFAC has found itself maintaining multiple systems and tools as it has expanded and evolved over the years. Within its design department alone, teams used different applications. So, when the commercial vehicle manufacturer launched a new leadership plan to strengthen the research and development (R&D) capabilities in its light truck division, it decided to implement the 3DEXPERIENCE platform to unify and standardize its product development processes.

DFAC tested the 3DEXPERIENCE platform out by using it to develop a new van, running on renewable energy. It hoped the platform would save time and was impressed by the outcome.

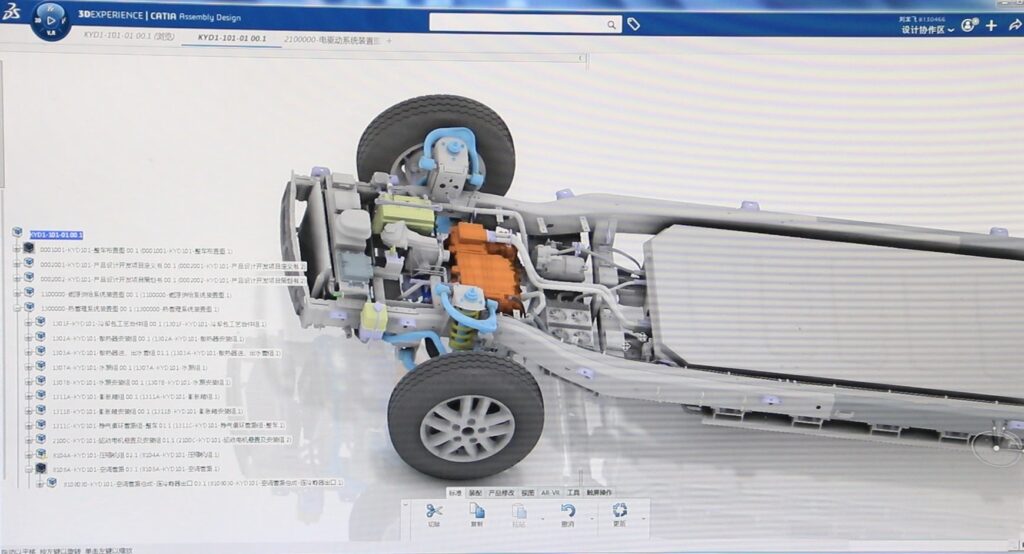

While DFAC’s legacy approach had made it impossible to see a full picture of the vehicle early on, this wasn’t the case for engineers using the 3DEXPERIENCE platform. The van team was able to design the vehicle body, chassis and electrical equipment, including interior and exterior components, in parallel within a single data environment with full version control.

Structural designers and general layout engineers could share data in real-time and collaborate on the same 3D models without the need to switch between applications or convert data files.

“The main purpose of the 3DEXPERIENCE platform is to improve our R&D efficiency by standardizing our processes, centralizing our data and providing management full visibility into what’s happening across the business,” said Zhang Jingfeng, general manager assistant at DFAC. “The R&D platform needed to be able to manage and assimilate data in real time.”

Today, the 3DEXPERIENCE platform lies at the heart of DFAC’s new light truck R&D vision and is helping to accelerate the product development cycle, improve data quality and keep costs under control.

Read the full story here to discover how DFAC has succeeded in making its design process 30% more efficient while reducing errors by 70%.