As much as 80% of a ship’s cost is determined in the early design phase, yet naval architects often make many of these crucial decisions with limited insights. Siloed processes and later-stage simulations mean that performance issues, manufacturability challenges and sustainability factors only appear further on in the development cycle when modifications are more costly and complex to make.

That’s beginning to change. Integrated modeling and simulation (MODSIM) and advanced virtual twin technologies are breaking down long-standing barriers between design, analysis and validation. Engineers can now simulate structural loads, fluid dynamics, electromagnetic behavior and more as they design so they can explore ideas in greater depth and validate them faster. At the same time, the virtual twin evolves alongside the vessel, linking design intent with real-world performance. The result is a more connected, proactive and data-driven approach to naval architecture that is transforming how ships are designed, built and sustained.

Introducing simulation into design earlier

Today, we’re seeing simulation move upstream, closer to the design phase itself. Here, instead of waiting for analysts to assess completed concepts, engineers can simulate as they build, creating a continuous feedback loop between modeling and analysis. This shift empowers teams to:

- Get feedback faster, encouraging greater creativity and reducing analyst bottlenecks and backlogs

- Use templates and rule-based automation to run compliance checks and design of experiment studies more efficiently

- Support early trade-off analysis and design decisions, reducing risk long before production begins.

MODSIM in action: a unified approach to innovation

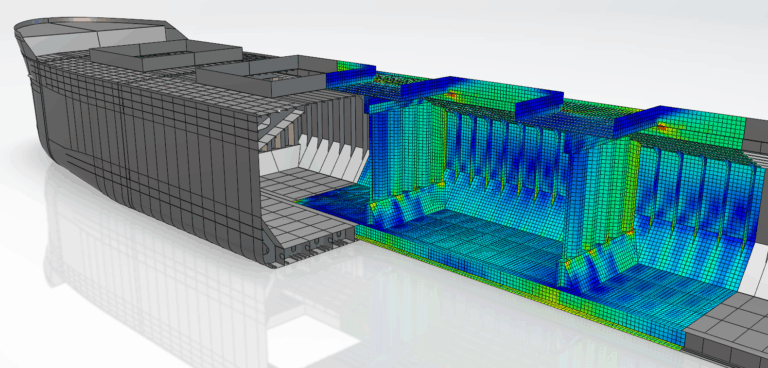

CATIA and SIMULIA on the 3DEXPERIENCE platform unite modeling and simulation in one environment. We call this approach MODSIM, which basically means that all design and simulation activities happens within a continuous workflow. There’s no need to import/export files, clean up geometries or rebuild models. In practice, this opens the door to a wider and more meaningful exploration of performance. Hull forms can be assessed under realistic operating conditions, propulsion systems can be refined for efficiency and noise reduction, and complex interactions between structure, flow and vibration can be better understood.

MODSIM supports innovation across a wide range of use cases:

- Hull integrity: Simulate hydrostatic and hydrodynamic loads for real-world strength validation

- Defense: Model blast impacts, optimize stealth features and run degaussing simulations to demagnetize metal hulls

- Electromagnetics: Plan antenna and radar placement to prevent interference on sail-equipped vessels

- Fluid dynamics: Design quieter, more efficient propulsion and reduce vibration for crew comfort and compliance

- Additive manufacturing: Simulate build processes to reduce prototyping costs and improve reliability

- Condition monitoring: Map sensor data to detect corrosion, weld fatigue or energy loss over time.

The benefits of MODSIM and the virtual twin

When MODSIM capabilities are harnessed to create a virtual twin of the ship, the benefits amplify. In the early design stages, shipbuilders can explore more options with confidence, seeing how each decision influences key parameters such as cost, efficiency and long-term performance. As the design moves into manufacturing and operation, the same shared model continues to guide planning, production, operational management and maintenance. Updates, modifications, performance enhancements and retrofits are reflected across simulations and analyses, keeping the virtual twin in sync with the operational ship and maintaining a continuous, traceable flow of information across the entire lifecycle.

This connected approach delivers measurable gains in:

- Speed: Faster time to market through integrated workflows and reduced rework

- Accuracy: Simulations remain synchronized with the latest design revisions

- Innovation: Generative design and AI-assisted solvers unlock entirely new configurations and concepts

- Sustainability: Optimize LNG tanks, biofuel systems and wind-assisted propulsion to meet IMO targets

- Maintenance: Deliver predictive servicing through sensor-linked simulation and operational data

- Compliance: Virtual testing supports classification and insurance validation, reducing reliance on physical trials.

The evolving role of the naval architect

Naval architects of the future will move fluidly between the physical and virtual worlds, supported by MODSIM and virtual twins that continuously inform decision-making. They will continue to provide strategic direction, intuition and creativity, while digital intelligence will accelerate exploration and validation. These advancing digital capabilities won’t replace naval architects and analysts. They will, however, expand the scope of what they can do.

In this new way of working:

- Ship design will be more about orchestrating systems such as propulsion, energy, materials and hydrodynamics

- AI and surrogate models will free up engineers to focus on higher-value innovation

- Creativity will be augmented, not fully automated.

To learn more about how the power of MODSIM and virtual twin capabilities on the 3DEXPERIENCE platform are setting a new benchmark for speed, performance and sustainability in naval architecture, check out the whitepaper “Generative Modeling & Simulation For Naval Architecture: The Future of Marine Engineering.”

Discover more

Validating Underwater Propeller Performance with SIMULIA PowerFLOW