It’s often said that today’s customers want an experience, not simply a product—and it’s hard to imagine a product that is more of an experience than a replacement limb. “The way people interact with prosthetics is so unlike any other product,” said Danielle Clode, who collaborated with the Alternative Limb Project to turn a prosthetic into both function and art. The Project considers prosthetics an extension of the wearer’s personality; founder Sophie de Oliveira Barata works with her clientele to find the right “fit” for their individual persona, and has used 3D printing to create stylized pieces for models, Paralympic athletes, disabled veterans, and music performers, among others.

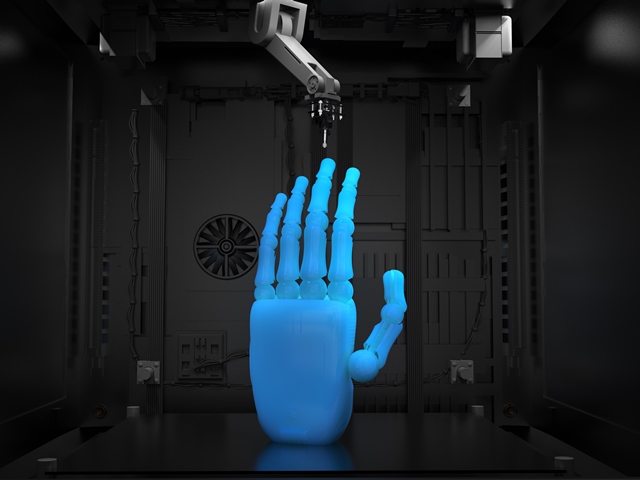

Barata and Clode created a prosthetic for model Kelly Knox, who was born without part of her left arm; it was displayed at Artful Innovation: Inclusive Design and Technology, at the Kennedy Center in Washington, D.C. The prosthetic is made from electroplated gold carbon fiber and clear acrylic layers, forming a layered and mirrored replacement arm that connects to interchangeable hands, one clear and one blue.

Clode’s 3D-printed prosthetics for human augmentation include her “Third Thumb.” This human hand extension has two motors that power the thumb movement by pulling on a Bowden cable—like a bike brake—made of Teflon tubing and wire. The motors get signaled by pressure sensors in the shoes and under the toes, which communicate with the thumb via a Bluetooth module worn on the shoe. The foot controls are “inspired by products that help to develop the already strong connection between our hands and our feet,” Clode said—like driving a car, operating a sewing machine, or playing the piano.

The structural cover for the hand and wrist cover for the motors are 3D-printed with resin; the thumb is printed with flexible filament. “3D printing is the perfect medium for this project, as it enables quick prototyping, customized designs of various hand sizes, and one-off production,” Clode said.

Barata’s first venture into 3D printing was a prosthetic leg for a soldier who lost his arm and leg after stepping on a mine. Her Alternative Limb Project gained international visibility when model Viktoria Modesta wore its prosthetic leg, overlaid with Swarovski crystal, while dancing on ice as the Snow Queen to the Coldplay song “42” during the 2012 London Paralympics closing ceremony.

Clode designed and printed her Third Thumb as an award-winning Master’s graduate project at the Royal College of Art in London. She received her Bachelor’s degree in Industrial Design from Victoria University in Wellington, New Zealand, so she’s attuned to both function and aesthetics.

“The value of the Third Thumb is to create a catalyst for society to consider human extensions, framed in an approachable, accessible design,” Clode said. “It is a tool, an experience, and a form of self-expression. When we start to extend our abilities, and when we reframe prosthetics as extensions, then we start to shift the focus from ‘fixing’ disability to extending ability.”