PT Pamapersada Nusantara (“PAMA”), wholly owned by PT United Tractors, Indonesia’s largest distributor of heavy equipment in the country, is an established player in coal mining contracting. In recent years, the company expanded into businesses in mining of gold, limestone, quarry management, clinker production, dam and road construction, and today, operates more than 10 subsidiaries. Its entire mining operation network is massive in both scale and diversity.

However, PAMA’s business expansion also brought about higher costs and increased complexity in managing siloed subsidiaries and far-flung mining sites. From geology, through to engineering, operations management and final sales for export, inefficiencies were arising at every juncture. Resource modelling and scenario updates were taking too long during the feedback period. Waiting for responses between siloed subsidiaries inevitably affected confidence in reporting integrity. This resulted in non-value-added tasks of manual checks and verifications of reports taking up precious technical personnel time.

In 2019, PAMA’s management took a major step embarking on a major organization-wide digital transformation program with Dassault Systèmes. The mission was to achieve end-to-end visibility amongst the subsidiaries to increase report reliability and improve people and process efficiency.

On 5 September 2019, both companies came together to organise a “Digitalization of Mining” workshop for 35 technical personnel in PAMA to bring to them insights into how smart digitalization, by bringing together and integrating siloed data meaningfully, can make vast improvements in consolidating PAMA’s operational visibility and optimizing its vast mining value chain.

Here are some of the key takeaways from the “Digitalization of Mining” workshop.

Enhancing Business Processes with Simulation Data Science

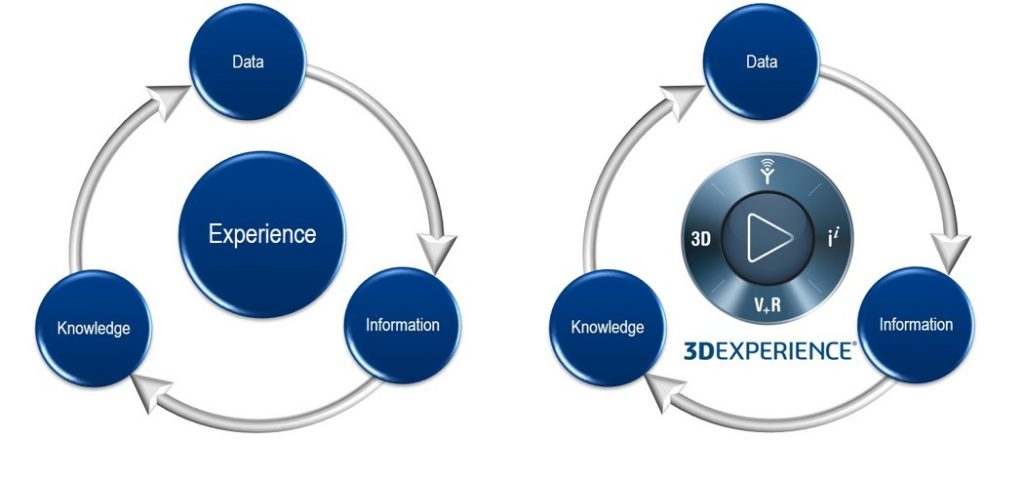

Data comes in many forms. In its raw format, data from a mine site yields a series of numerical calculations of tabular stress and strain on geological structures. However, on its own, without information in context, it lacks meaning or purpose.

Information is data with context – it gives meaning to the numbers, such as contour plots of stress/strain, energies and deformations. Information is what people use to make business decisions.

Knowledge is the insight that comes from the application of this Information to solve a problem, such as evaluating stress/strain states in geological structures or recognizing trends in data.

The desire for Knowledge causes us to ask questions which require more data, and the cycle continues. With proper management of data and information, the company builds up its Experience in application of Knowledge to make better decisions. Think of this Experience as a time-machine, enabling the company to look back in time to discover which operational scenarios yielded the highest productivity and best results.

Having this kind of critical Knowledge at the fingertips speeds up the company’s decision-making, troubleshooting, and performance efficiency.

The 3DEXPERIENCE platform consolidates this dynamic Data-Information-Knowledge cycle into one “single source of truth” on a 3D virtual experience platform to develop simulated production models. At a glance, the company is able to step back, reassess its operations through simulation data science and enhance its business processes to optimize the entire mining value chain.

Digitalized Geological Mapping with GEOVIA

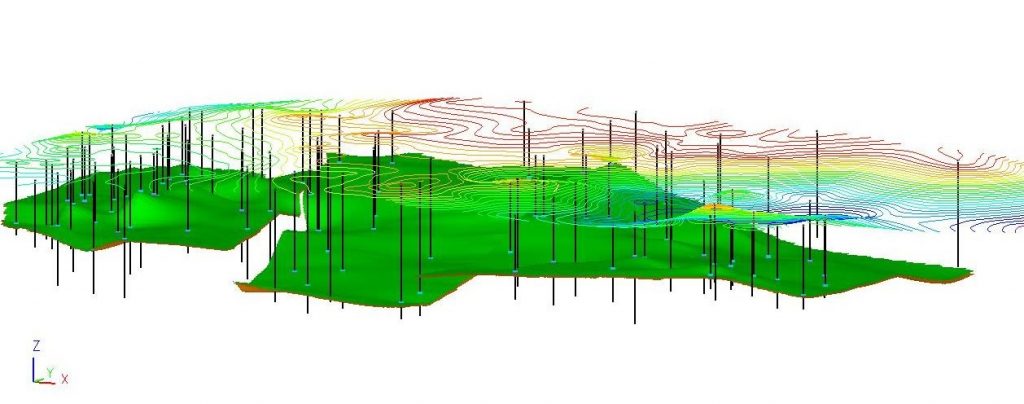

With high grade deposits becoming less accessible, mining businesses like PAMA need to explore more remote locations and deeper beneath the surface. This means that mining and processing must become more efficient, and adopt lean practices to minimize waste and environmental impact.

GEOVIA, Dassault Systèmes’ virtual planet modelling and simulation software, provides 3DEXPERIENCE virtual platforms to create 3D models of geophysical and geological observations to help manage resources, identify potential hazards, and quantify geological processes. Simulated geological models allows mine engineers to identify drilling options that offer the safest and most economic, efficient, and effective mine development plan.

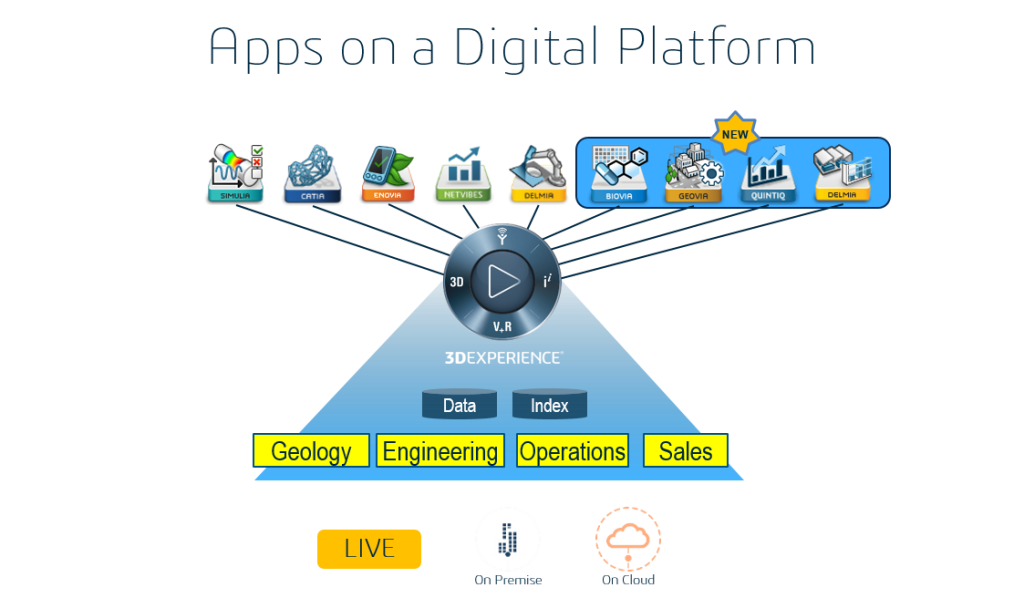

Benefits of 3DEXPERIENCE

Dassault Systèmes’ 3DEXPERIENCE platform creates accurate, data-driven 3D simulations of large-scale mining operations through a single virtual experience platform that is able to link all organisational business processes, from geology, engineering, operations to sales.

On one single platform, everyone collaborates and shares reports throughout the entire Data-Information-Knowledge cycle.

With the 3DEXPERIENCE platform, companies like PAMA are able to rate the risks and rewards of extraction methodologies on a site before committing capital and personnel time, as well as mapping out short-term and long-term schedules to plan out operations for drilling, crushing and extraction work.

In addition, by virtually simulating entire mining processes on the 3DEXPERIENCE platform, on-site personnel are empowered to test out new methodologies of work processes in a very cost-effective manner. Every test can be conducted on the virtual platform without any need to deploy any capital to find out what works.

For further discussions on how Dassault Systèmes can partner with mining businesses to unlock value in mining operations, please reach out to me at Riduan.YAACOB@3ds.com