Dassault Systèmes was a Silver Sponsor of the 11th Asian Downstream Summit 2018, the largest conference and exhibition dedicated to Asia’s refining, petrochemical and chemicals industry, which took place from 31 October to 1 November 2018. It is the anchor oil & gas event of the Singapore International Energy Week (SIEW), hosted by the Energy Market Authority of Singapore, which brought together over 10,000 industry professionals and focusing on technological innovations that are changing the downstream oil & gas sector. This year’s Asian Downstream Summit focused on technological innovations, Industry 4.0 and digital transformation in the Oil & Gas industry.

We are proud to announce that Dassault Systèmes won the ‘Best Innovative Technology for Improving Operational Efficiency’ award at the Asian Downstream Summit Digital Transformation Awards, which recognises top innovative solution providers across the downstream oil & gas sector in Asia for their outstanding commitment to a sustainable energy sector. Dr Koh Poh Koon, Senior Minister of State, Ministry of Trade and Industry & Ministry of National Development of Singapore, who was the Guest-of-Honour at the event, presented the award to Dassault Systèmes’ Value Solutions Channel Leader for AP South, Ding Ming Chee, during the Opening Plenary.

This marks an important industry endorsement in Asia of Dassault Systèmes’ Turnaround Planning & Management industry solution powered by the 3DEXPERIENCE platform, which we exhibited at our booth during the Summit.

Dassault Systèmes’ Presentations during the Summit

During the Summit, Philippe Audrain, Dassault Systèmes’ Business Consultant Director for EPU (Energy, Process & Utilities) and Stephen Stein, Dassault Systèmes’ Senior Business Consultant for EPU, were invited to present on the impact of digital transformation on downstream operations and transforming plant turnaround planning and management with the 3DEXPERIENCE platform respectively.

In this blog, we bring you some key takeaways from our speakers’ presentations.

Q&A with Philippe Audrain, Dassault Systèmes’ Business Consultant Director for EPU

1. What does the subject of digital transformation mean to you and please highlight why you think there is a need for a digitalization and transformation roadmap in downstream oil and gas.

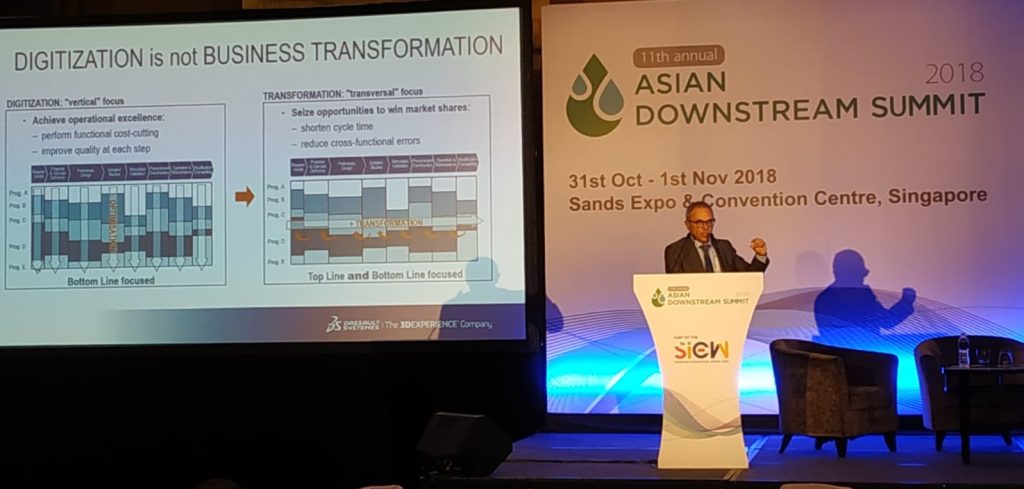

“Digital transformation” is not about digitalizing existing processes but changing those processes to make them more efficient (thanks to capabilities provided by digital platform based technologies). It can lead to a real and fruitful “Business transformation”. The paradigm to achieve transformation is to move from a vertical silo existing approach to a transversal lifecycle approach provided by digital continuity.

This is relevant to the downstream oil & gas sector facing competitive environment and looking for CAPEX and OPEX optimization.

2. How do you see the role of the Industrial Internet of Things in refining, petrochemicals & chemicals? What are the key benefits and opportunities of using IIoT solutions in downstream operations?

IIoT is the most effective way to connect the digital world with the real world, get them in sync so that they can get advantage of each other. The real world can help to tune digital models to let them behave the same way as if real. And the digital world can help understand a past event, monitor and support the current operations, prepare a future operation, predict future event.

3. What are the latest technology adoptions by downstream operators in Asia? Are there any success stories that other operators can learn from?

Some downstream Asian operators already adopted advanced digital transformation technologies. Other downstream operators can leverage these success stories as well as others provided by industries operating similar continuous process capital facilities.

4. What are your views on Asia’s downstream industries rate of digitalization as compared to counterparts in other regions i.e. America, Europe and the Middle East markets?

Thanks to the growing Asian economy, most of the worldwide capital facilities greenfield projects are located in this geography. These new projects are real enablers to adopt the most efficient new digital technologies to get successful projects results. These are the same digital technologies that can apply to operation and maintenance. Consequently, we think that Asia rate of digitalization is at least the same as in other markets.

Presentation by Stephen Stein, Dassault Systèmes’ Senior Business Consultant for EPU

Plant turnaround planning and management is a highly complex business process, involving many stakeholders across multiple disciplines, such as geophysics, geology, engineering, operations and asset maintenance, and managing huge amounts of information and data. Successful integration of this information and data is often the main factor in unlocking the inherent value of refineries and petrochemical plants.

Dassault Systèmes 3DEXPERIENCE platform presents a whole new way for refining facilities to drive unprecedented agility and efficiency for tough plant lifecycle management endeavors through the following transformative drivers:

- A streamlining of administration, compliance and work processes over a common platform

- A 3D virtual plant data model to achieve safe, on-budget and on-time completion of a turnaround lifecycle event

- Real-time information sharing and capture to enhance collaboration, reduce handover documentation, and save millions in future turnaround costs with continuous knowledge

So how can your refinery or petrochemical plant benefit from the 3DEXPERIENCE platform?

The key element is the creation of the 3DEXPERIENCE Twin is a 3D virtual ‘twin’ or replica of the elements and dynamics of the actual refinery or petrochemical plant, offering a ‘Single Source of Truth’ approach to data analytics by integrating and mapping out all plant operational information and real-time data in the 3D virtual environment. This approach provides one unified 3D view of all the plant’s operations to multidisciplinary teams, allowing them to virtually collaborate, plan, simulate and predict real-world performances of plant & equipment before actual operation.

With a deeper understanding of potential asset performance earlier in the plant operational process, oil & gas businesses can quickly detect and resolve issues, better comply with regulatory requirements and explore alternatives that will help optimize asset value.

Missed us at the Asian Downstream Summit or want to meet us again?

For more details about what we showcased at the Asian Downstream Summit, go to our Turnaround Planning and Management industry solution site or contact us at aps.marketing@3ds.com

Register here to hear about our upcoming events, webinars and receive news from our global innovation labs.