Separate configure-price-quote (CPQ) systems have been on the market for well over 10 years and many industrial equipment manufacturers already depend on one. It has been a tool to turn complex customer requirements into a product configuration and a quick quote.

Still, customer expectations and sales experiences continue to shift. Across every industry, product development is leaning towards higher levels of customization. Customers want machinery that perfectly matches their processes, constraints and environments. Industrial equipment manufacturers, in turn, need to deliver that choice without losing control of cost, complexity or lead times. Balancing personalization and standardization, then, has become a competitive strategy, not simply an engineering concern.

A CPQ tool is even more important when you consider that today’s buyers complete nearly 80% of their decision-making online before speaking to anyone. They expect digital tools that can show them what’s possible, answer questions instantly and reflect real engineering logic.

CPQ solutions available on the market have already pushed quoting cycles from weeks and days to almost instantaneous results. Beneath that speed, however, sits a growing technical complexity: product portfolios with increasing variability, 3D models that carry engineering intent, generative designs capable of thousands of variants and parametric structures that adapt as inputs shift. Add to that supply chain fluctuations, lifecycle management economics and sustainability considerations and CPQ must continue match this pace.

CPQ and industrial equipment trends

Quoting is a decisive moment in the customer journey. It connects product definition, commercial strategy and long-term economics. Within industrial equipment, that moment is increasingly defined by three major trends:

- Production of one: Even machines that appear standard rarely are. Internal configurations vary by performance needs, regional rules, operating conditions or customer-specific parameters. Sales teams must offer that flexibility while manufacturers must preserve global consistency and margin. The configuration chosen at the quote stage often dictates everything that follows.

- Custom development at standard prices: Buyers expect the clarity of a consumer-grade product experience, even when the product is a multimillion-euro asset. They want to explore options, understand implications and see how choices affect cost and delivery time. Meanwhile, product teams need insight into how customers are configuring equipment in the real world.

- Lifecycle and service intelligence: A quote no longer stops at the machine. Customers evaluate maintenance schedules, spare parts, service kits, energy consumption and environmental impact as part of the decision. Manufacturers who bring lifecycle clarity into the sales conversation build trust faster.

Connecting product development to the sales experience

Parametric designs, simulation-driven engineering and continually updated product rules mean sales software must understand how a product is constructed, not just how it’s priced. That’s why a standalone CPQ tool will struggle when design logic shifts weekly or when new product options influence manufacturing or services downstream.

A better way forward brings CPQ into the same environment that defines the product itself, so that:

- Product portfolio updates appear instantly in sales tools

- Engineering rules shape manufacturing feasibility

- Lead-time changes are visible at the moment of configuration

- Service updates automatically influence lifecycle costs.

In many ways, the sales experience becomes a natural part of the product lifecycle instead of a disconnected process. This way, when the portfolio expands, everyone across the business is updated. When a configuration changes production lead times, the salesperson can notify prospects and customers. When service teams refine maintenance requirements, the quote reflects it automatically.

A unified platform for the entire customer experience

Dassault Systèmes has spent decades shaping the systems that industrial equipment manufacturers use for design, simulation, engineering and manufacturing. Extending CPQ into the same environment where products are defined, validated and prepared for production is a natural progression. This unified approach particularly suits industries where complexity is the rule, not the exception.

Here’s what a typical industrial equipment sales experience looks like when CPQ is managed within the 3DEXPERIENCE platform and synchronized across the business:

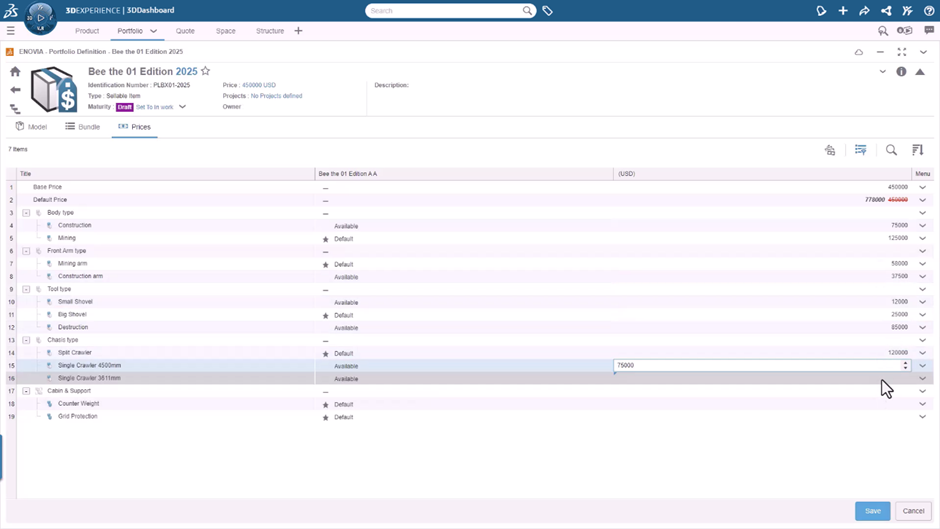

1. Portfolio and product definition The product portfolio is defined with all its variants, options and parameters, along with the rules governing them. Decisions are made about which features are exposed to customers and which are only relevant for internal use. Everything is defined in the same environment, complete with rules and configuration engine – a perfect combination of commercial and technical product definition.

2. CPQ ready engineering

Engineers work on the product in the normal way: they prepare 3D models, parts and assemblies, and apply configuration definitions from above. The output of this work is the Product Virtual Twin – a configurable engineering bill of materials (EBOM). In a typical case, this product twin/EBOM contains far too many details for a sales situation. Therefore, the 3DEXPERIENCE platform provides the capability to develop a connected configurable Commercial Twin. This lightweight, visualized and configurable 3D representation is ideal for CPQ usage, and is fully connected to the original Product Virtual Twin, instead of an exported stand-alone 3D model.

Going forward, the configurable product virtual twins can also be used for manufacturing and service definitions, leveraging the sold product configuration and extending the value for a total lifecycle offering.

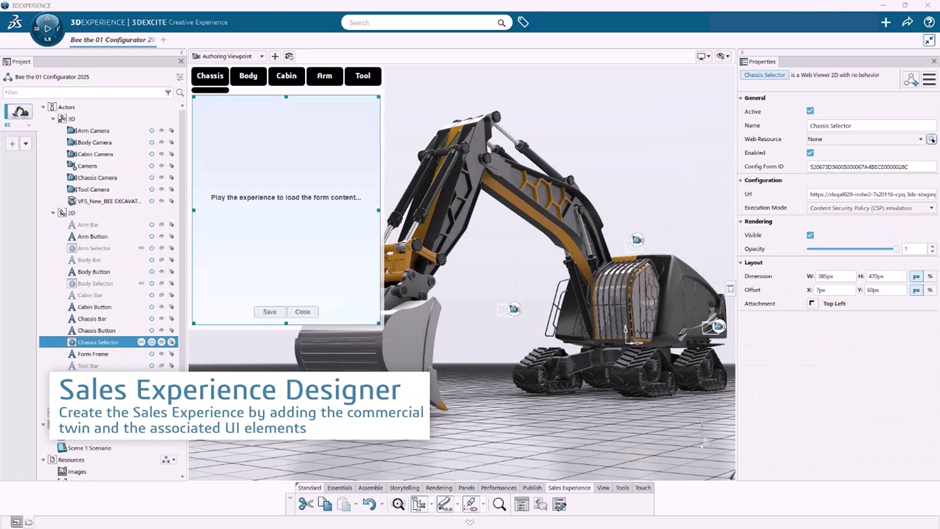

3. Sales experience development – CPQ on the 3DEXPERIENCE platform

Commercial team build the reusable customer-facing sales experience with a compelling visual 3D environment and user interface. This is based directly on the portfolio and product definitions and the configurable Commercial Twins above, without any re-writing, specially developed logic or additional complexities. Any changes in the product offering, variation or designs are immediately reflected in this sales experience.

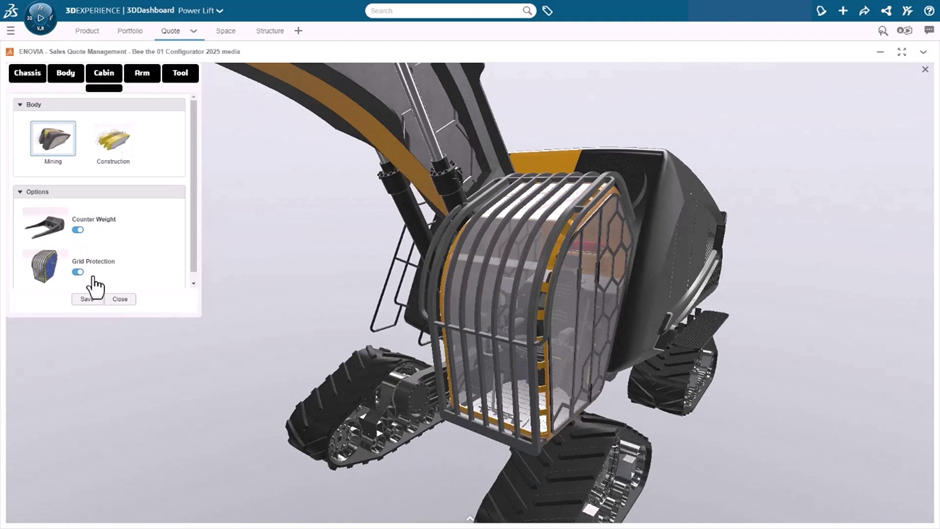

4. Sales execution with the 3DEXPERIENCE CPQ and Sales Experience Sales uses the company-wide product portfolio to find a product, kick off a new quote process and launch a guided sales experience. The Commercial Twin promotes a transparent and compelling dialogue with the customer to define their ideal product configuration and the best offer.

Dassault Systèmes’ end-to-end, platform-driven approach to CPQ results in a new kind of sales experience that connects the sales domain to an ever-evolving product offering in a way that previously has not been possible.

The result is a CPQ process that mirrors how industrial equipment is developed, sold, manufactured and serviced rather than a disconnected add-on tool to the process. And it aligns every choice a customer makes with the reality of how the machine will be built, shipped and sustained