We see product complexity increasing in everyday consumer products from app driven light fixtures to vacuum cleaners. This evolution to give consumers smart and automated products impacts the way engineers work. As products shift from mechanical only to software driven, how have consumer product engineering workflows changed ? Whether home furniture and decor, sports equipment or DIY and garden tools increasingly engineers must navigate product requirements that elevate the consumer experience such as:

- Configurable designs allowing options for personalization

- Connected products that can be scheduled and controlled remotely

- Software and sensor-driven small appliances and autonomous single purpose robots

For engineers and manufacturing leaders this evolution requires practical, cost-effective workflows that simplify complexity while extending beyond CAD and physical testing.

At 3DEXPERIENCE World 2026, February 1-4, in Houston, TX, the Consumer Industry team will showcase how engineering can apply cloud-based solutions to modern consumer products via the 3DEXPERIENCE® platform. Our team put together a list of the top ten ways consumer goods product engineers can maximize their visit.

10. Get Insight into Reducing Engineering Complexity with the Evolution of Consumer Products

Integrating mechanics, imbedded electronics, software, and personalization and sustainability requirements adds new levels of complexity. How does engineering manage these requirements without slowing down development? Visit the Consumer kiosk in the Dassault Systèmes booth. See demonstrations of new ways of working, such as.

- How to work in parallel employing multi-discipline engineering.

- The way to align in real-time before full handoff with manufacturing and manufacturing planning teams.

- How to apply traceability from concept to test and understand how design choices and decisions align with product requirements.

9. Visit the 3DEXPERIENCE Theater, Learn How to Evolve Your Workflow to Improve Product Development

Today’s smart and software-driven consumer products have engineers using concept and product design as a foundation. But they also extend SOLIDWORKS workflows in order to have earlier insight into performance, manufacturability, and ways to simplify variability features. Join our experts, Eran Reinshmidt and Annabelle Grauer in the 3DEXPERIENCE Theater. “Product Design Evolved. Has Your Workflow? What Every Consumer-Product Engineer Should Know” Tuesday, February 3 at 2:00pm.

8. Learn How MODSIM Offers Insight Earlier and Improves Design Decisions

Some engineering teams apply simulation including Fine Element Analysis (FEA) for detailed design validation and to investigate post-release failures. Visit the Consumer team to see integrated modeling and simulation (MODIM) in action from the early concept phase throughout the development lifecycle. This consumer product engineering workflows shift makes sense for design engineers to evaluate product strength, durability, electromagnetic signals, weight, assembly and maintenance options earlier to reduce late design changes and rework. Consumer customers like high end helmet maker, Ruroc report using a MODSIM approach allows virtual prototyping which reduces the time by minimizing the amount of physical testing. Already used in mature industries like automotive, this integrated approach saves time, money and environmental impact. SOLIDWORKS users have access to these same enhanced capabilities.

7. Understand How Scalable, Cloud-based Workflow Helps Teams

Consumer product teams work and suppliers and manufacturing partners that usually operate across different locations and event time zones. Cloud-based access gives engineers the ability to collaborate, run simulations, and manage product data on demand. A cloud-based approach eliminates file version headaches because there is only one version. Software accessible via the cloud that provides users with a single version of the product model they should have access to. Companies have a secure way to manage intellectual property, collaborate and share workflows and data in real-time.

6. See How to Connect Engineering Decisions to Manufacturing Planning Earlier

How does engineering and manufacturing optimize how they operate? What if engineering had insight into design decisions so they could work in parallel with engineering? Manufacturing planning can begin conceptually while engineering finalizes form, function, materials, and defines key performance targets. Using a collaborative platform to share and collaborate in real-time shortens the product launch. Production can occur much sooner if engineering and manufacturing align early. Manufacturability, sourcing options, tooling and cost drivers begin well before the design freeze/validation phases. The Manufacturing Bill of Materials (MBOM) creation accelerates when engineering work together early in development. Ask to see a demonstration showcasing SOLIDWORKS and manufacturing scheduling and production planning software modules.

5. Enable Personalization Without Increasing Complexity

Personalized and configurable products seem to be proliferating. Many consumer product companies go after market share by meeting the consumer preference for customizable products. How does product development support multiple product options and variants without creating an unmanageable nightmare of complexity? Try our configuration demonstration. Talk to our experts to understand ways to meet product personalization objectives with solutions on the 3DEXPERIENCE platform.

4. Add the Power of Digital Continuity to Reduce Rework

The power of digital continuity when using SOLIDWORKS on the 3DEXPERIENCE platform saves time, minimizes errors and reduces delays. Visit the consumer team and one of our experts will demonstrate digital continuity on the platform. Designers and their product team can to work on a single product model from concept through manufacturing and avoid rework and late stage changes. See the value of connecting people, processes and data in a cloud-based environment.

3. Learn the Benefits of Effective MCAD and ECAD Collaboration

Another key point for those developing complex, connected products: the best way to avoid slowing down development time. Consider changing your MCAD/ECAD process. A change to the traditional consumer product engineering workflows that improves collaboration offers a solution. Integrating collaboration across teams simplifies the work of embedding electronics into a mechanical design. Our Consumer Industry experts will share the building blocks to better MCAD and ECAD collaboration in development such as:

Adopt standards – adopt a unified set of symbols and parts across your engineering projects to streamline the entire process. By minimizing the time your

engineers spend creating or interpreting custom symbols, they can focus on core design work.

Automate version control – Eliminate manual tracking of design versions often leads to inconsistencies and errors as team members of every discipline inadvertently work on outdated versions of designs or documents.

Leverage past designs – Harness the power of circuit design reuse through macros. This elevates electrical design using SOLIDWORKS by facilitating a seamless and parametric connection between mechanical and electrical design projects.

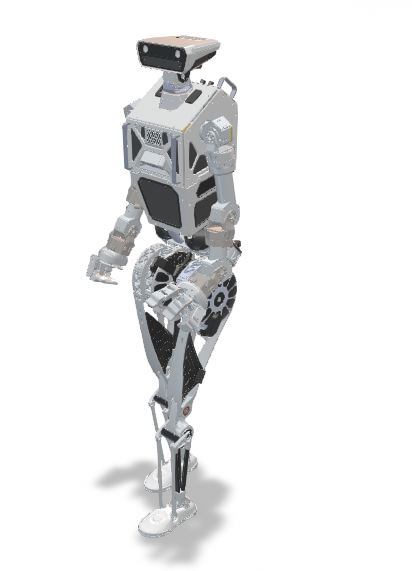

2. Meet a Humanoid Robot, See How Traceability Simplifies Development of a Robot Vacuum

Whether designing a robotic vacuum for the home or a full humanoid robot, engineers designing complex products want the best tools. Using a platform approach along with SOLIDWORKS design tools offers consumer product engineering workflows with a record of each product requirement and how it’s met. The booth team welcomes Themis, the humanoid robot (designed with SOLIDWORKS) by Westwood Robotics who will greet visitors. And the Consumer team will show the development of distant ‘cousin’ to Themis –a robot vacuum. The team can’t wait to share the solutions SOLDWORKS users can use to simplify the development of robotic products and other complex consumer products.

1. Network, Meet the Experts, Score Some Collectable Robot Stickers!

Finally, networking with others in your industry or discipline offers insights and key learnings from other companies. The Dassault Systèmes booth offers one of the best places at the show to engage with your fellow SOLIDWORKS users and talking to the experts who work with companies across your industry every day. Interested in benchmarking with other consumer goods manufacturers’ best practices? Curious about new engineering workflows for consumer products? Want to ask questions or schedule a time to discuss a specific topic area? And, why not carry home the collectible robot stickers (a different one will be available at each kiosk) Your co-workers who couldn’t make the trip or for your family will be happy.

Stop by our theater talk, visit the Consumer kiosk or we’ll catch you at the events. The Consumer team looks forward to seeing you in Houston.

.