What advantages does digital transformation offer consumer goods manufacturers?

Digital disruption embraced by companies in aviation and automotive because of product complexity and regulations offers consumer goods companies the same benefits. Facing an era with strong expectations for sustainability, personalization, and smart products consumer products companies manage increasing product complexity. And, experts see AI use in engineering accelerating.A McKinsey study of CPGR companies finds 71% of CPG leaders now use AI in at least one function (McKinsey 2024). With more than a two-fold jump in just a year, is growth suggests as AI matures more adoption will follow in other industries. So, consider the question facing today’s Research & Development leader: How might consumer product development with PLM and SOLIDWORKS CAD provide the right foundation for today?

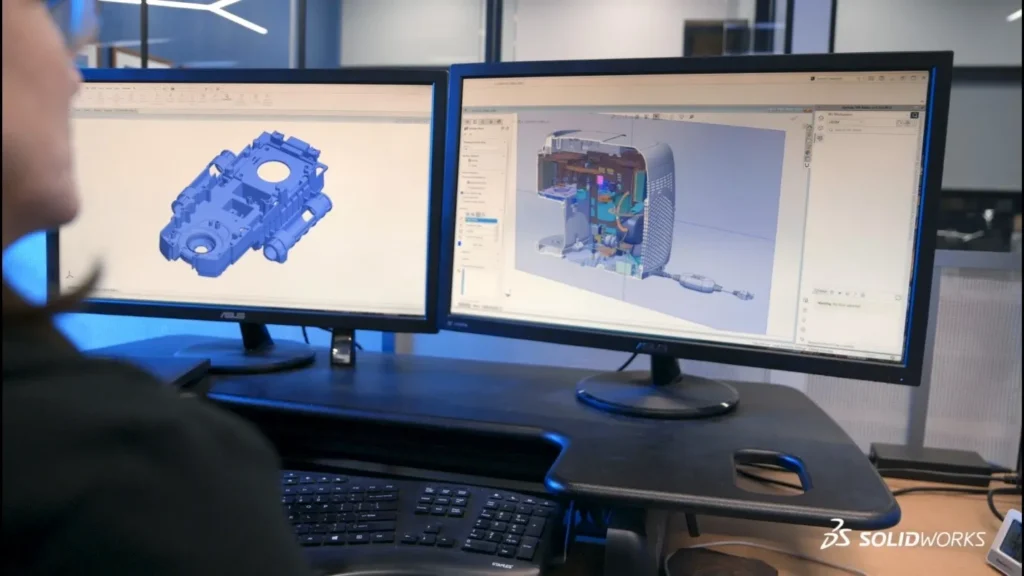

Consider why engineering teams (CALOI, ColdSnap, OtO) adopt a platform. A single version of the truth aligns an organization. A platform where the engineering product model lives and where teams collaborate across development and manufacturing simplifies processes. A platform-based digital transformation offers continuity, transparency, and agility. Plus, entry level (who used SOLIDWORKS tools at their university) and more experienced engineers both appreciate avoiding non-value added tasks, easy collaboration, and intuitive science-based tools for simulation.

Trends Shaping Consumer Goods Product Development

No matter how large (or small) the consumer product company, technology is viewed as a key enabler to making their business a sucess. Consumer sentiment, regulations, competition and the desire to attract top talent all contribute to the need for having the right solutions in place to grow and improve product innovation and development. How do companies get ahead of industry trends so they dont become an obstacles or a missed opportunity? Using SOLIDWORKS plus the 3DEXPERIENCE platform offers the tools and approach to face these challenges head on:

• Develop smart and connected home devices (solving issues around integration across hardware, software, and services).

• Simplify sustainable product design to meet consumer and regulator expectations for eco-friendly materials, lifecycle tracking, and reparability.

• Improve profitability in product development while adding new functionality or options for personalization (i.e., custom finishes, modular features, and aesthetic and size variations).

The drag of traditional processes (a frequent source of bottlenecks) can be removed. Digital tools offer integration instead of silos, real time insight instead of disparate and delayed information–all of which speeds up the pace of decision making and product development. As products continue to become more connected and complex engineers need an ecosystem that keeps up. Engineering complex products requires 3D and 2D CAD, virtual testing, visualization, and collaborative design—without silos. Check out the ways smart product design using SOLIDWORKS plus the 3DEXPERIENCE platform helps. Can your company benefit from a cohesive approach to solving enginering challenges from the simple (eliminate file version issues) to complex (streamline multi-discipline engineering).

PLM for Consumer Goods Engineers: A Backbone for Innovation

PLM for consumer goods gives engineering teams control over every phase of the product lifecycle. It lays down the rails so data, materials, components, and manufacturing intent all live in one shared space. Engineers gain traceability, reduce rework, and make evidence-based design decisions—from BOM (Bill of Materials) through MBOM, supplier sourcing, regulatory compliance.

For example, in the Home & Lifestyle space, virtual prototypes, digital twins, and simulation enabled via integrated PLM let engineers test durability, assembly, and material impact before committing to physical builds. When teams use up-to-date, centralized data, they avoid redundant changes, costly prototype cycles, and poor manufacturability late in development. Check out the paper that delves into how companies can benefit from ‘worry free PLM‘

Advancing SOLIDWORKS CAD for Product Development Success

SOLIDWORKS CAD already the chosen tool for many engineering teams in the home, lifestyle, and consumer goods sectors. SOLIDWORKS delivers robust sketching, modeling, surfacing, assembly design, and sheet metal features. But when you combine it with the 3DEXPERIENCE platform, engineers unlock more: cloud collaboration, real-time versioning, concurrent engineering, and high-quality photorealistic rendering.

Engineers can iterating rapidly simulating product performance. Whether performing structural, thermal, or fluid flow analysis, or testing design aesthetics via rendering all teams can access all data. Using platform-based consumer product development with PLM and SOLIDWORKS CAD improves workflow, reduces iterations, decreases time-to-market, and improves manufacturability.

Connecting Design to Manufacturing Planning

Using a Product Lifecycle Management (PLM) strategy for consumer goods with SOLIDWORKS CAD allows manufacturers to manage a product’s entire journey–idea to through production and use and end of life. When applied to product development SOLIDWORKS users on the 3DEXPERIENCE platform reap the inherent benefits PLM– streamlined multi-discipline engineering and real-time collaboration across design and manufacturing. Engineers can embed manufacturability rules, supplier input, material constraints early. Early insight minimizes surprises in tooling, assembly, packaging. Data from engineering virtual testing and validation: from form and aesthetics to structural and functional performance all resides on one platform. Manufacturing planning engineers can work with production to optimize the assembly process, reduce first-article failure, ensure regulatory & safety compliance, improve cost efficiency, and ensure higher quality.

Consumer companies investigating how to advance consumer goods product development with SOLIDWORKS CAD and PLM can find more details and case studies on our website.

Take Action – Explore key initiatives for advancing SOLIDWORKS CAD for product development

Here are three SOLIDWORKS initiatives that support SOLIDWORKS CAD and PLM for consumer products by using the 3DEXPERIENCE platform and solutions to address engineering priorities:

- Integrate design and simulation to accelerate consumer product innovation –Applying simulation during design, a benefit of a product lifecycle management approach, delivers faster innovation while maintaining reliability. Engineers in design and simulation disciplines work together to turn ideas into producible designs more quickly.

- Streamline Design to Manufacturing – Read story about how icecream appliance maker, ColdSnap uses SOLIDWORKS CAD design tools on the 3DEXPERIENCE platform allowed the company to accelerate the design, prototyping, redesign, and preparation for manufacturing processes.

- Collaborative Engineering on the Cloud – Scale your product development as projects require with the 3DEXPERIENCE platform. Connect distributed teams, contractors, and suppliers to work together in real time while restricting data access based on a user’s role. With a platoform approach, design versions stay in sync; feedback flows in real-time, errors drop, and everyone avoids version control and file conversions issues.

Why pursue consumer product development with PLM and SOLIDWORKS CAD?

Consumer goods companies stand at a crossroads. They seek the right tools for their teams to develop products that meet requirements ranging from consumer preferences, regulation, sustainability goals, and rapidly advancing data requirements to exploit the value of AI. To excel, finding tools that enable intelligent collaboration, agile development, and digital continuity becomes imperative.

SOLIDWORKS CAD and PLM for consumer products, available via the 3DEXPERIENCE platform, provides a needed foundation. Meet product goals, accelerate innovation, ensure design-to-manufacturing alignment, and capture a competitive advantage. Explore how your consumer product team can embrace this digital future proactively.