In the race to meet rising consumer expectations, evolving regulations and internal sustainability commitments, packaging has become one of the most urgent transformation priorities for consumer goods companies. The challenge is no longer whether to act—but how to move fast, make the right trade-offs and modernize processes without compromising product quality or profitability.

Insights throughout the Delivering Sustainable Packaging Success playbook reveal a clear theme: sustainability and economic performance are no longer competing priorities—they’re increasingly interconnected. Leaders who evolve their packaging strategies now are finding ways to unlock both operational efficiency and brand advantage.

The Pressure Is Mounting—But So Are the Opportunities

Consumers make product choices in mere seconds, so packaging remains a powerful signal of value, trust and brand purpose. Today, with 80% of consumers favoring minimal packaging and retailers placing sustainability among their top supplier criteria, packaging decisions influence not only cost structures but shelf performance and customer loyalty.

At the same time, sustainability regulations continue to tighten across regions, making vague claims or poorly verified materials a growing business risk. The playbook emphasizes the importance of traceability and robust environmental reporting, especially as claims like “recyclable,” “recycled content,” or “biodegradable” face increasing scrutiny.

These pressures add complexity, but they also create an opportunity to modernize outdated processes and accelerate innovation. Leading brands are treating packaging transformation as a value-creation lever—not just a compliance exercise.

Why Traditional Packaging Workflows Fall Short

Many CPG teams still operate in siloed environments: design teams experimenting with materials on one side, manufacturing teams constrained by existing equipment on another, and marketing teams navigating label changes in isolation. The result? Inefficiencies, repeated work, late-stage rework and slower time to market.

The playbook highlights how even small changes—an artwork update, a shift in material availability, a modification to storage instructions—can ripple across cost, quality and launch timelines if not managed collaboratively.

The Shift Toward Virtual, Data-Driven Packaging Development

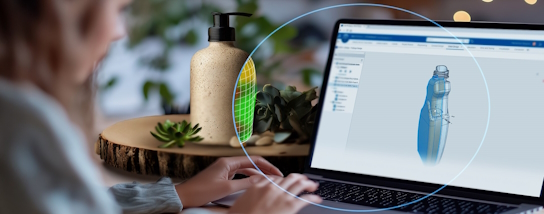

One of the most transformative ideas presented in the playbook is the shift from physical iterations to virtual prototyping, simulation and digital collaboration across the packaging lifecycle.

According to the insights, virtual modeling enables teams to evaluate packaging strength, manufacturability, recyclability and even consumer experience before producing a single physical prototype. This not only accelerates innovation but helps teams balance material lightweighting with performance—critical as companies explore biomaterials, recycled content and alternative fiber-based solutions.

Simulation also plays a key role in validating sustainability claims. For example, if consumers must separate materials for recycling, teams can use modeling to ensure those materials actually pull apart cleanly, avoiding the risk of creating “aspirationally recyclable” packaging that fails in practice.

Lifecycle assessment (LCA) emerges as another foundational tool, enabling teams to measure the environmental impact of decisions earlier, compare material options, and align with retailer expectations. With up to 80% of a product’s environmental impact determined during the design phase, better decision-making upstream leads to measurable progress downstream.

A More Resilient, Circular Packaging Ecosystem

Across the case studies referenced in the playbook—from wine producers accelerating approvals to packaging manufacturers optimizing preforms—leaders are proving that modernizing packaging development creates a more resilient, circular-friendly value chain. Gains come not only from sustainability, but from speed, agility, traceability and lower costs associated with reduced rework and fewer physical tests.

Ultimately, the path forward is clear: sustainable packaging isn’t just a responsibility. It’s an opportunity to build stronger brands, more efficient operations and more future-ready product portfolios.

Want to Go Deeper?

To explore the strategies, case studies and recommendations in greater detail, you can visit the Dassault Systèmes website to learn more and download the full Delivering Sustainable Packaging Success executive playbook. It offers an end-to-end look at how leading CPG companies are transforming their packaging programs for both sustainability and growth.

👉 Read more HERE