A few months ago, we published our 2020 corporate report. In addition to reflecting back on how our business navigated the challenges of one of the most unusual years in history, the report is full of many compelling and inspiring stories. We are pleased to share those with you here. This post focuses on the section Where the future takes off.

From the air to the ground to the sea, transportation systems are becoming more fluid, quiet and energy-efficient. Virtual universes are helping to facilitate this change. Here are a few stories of innovations in mobility supported by the 3DEXPERIENCE platform.

New space

Sixty years into the Space Age, the industry is undergoing a substantial transformation: from being driven by governments to being widely advanced through entrepreneurs in the private sector. Launches are more frequent and the number of operational satellites orbiting the Earth could rise to several tens of thousands in the next 30 years.

One of the shortest-term projects is making the Moon a staging post for more distant space travel. Interstellar Lab is one company that’s preparing for this. They build experimental, bio-regenerative, modular, space-ready, controlled environment stations called EBIOS. Virtually everything within these stations is recycled, making water, air and food as renewable as possible. Our cloud-based 3DEXPERIENCE platform and Reinvent the Sky solution help securely coordinate the various specialists (biologists, aerospace and aeronautical engineers, experts in control systems and materials science, architects and mathematicians) who are contributing their skills to refine and optimize the design and production of EBIOS. Leveraging a virtual experience twin of the station will become hugely valuable as Interstellar Lab moves toward making and operating these modules.

Reinventing mobility

Breakthrough innovations are coming from mobility companies connecting newer environmental priorities with long-standing historical objectives including efficiency, profitability and regulatory compliance.

A big challenge in the mobility sector is effective travel between locations poorly served by high-speed trains and regional airlines. Helicopters offer an approach, but they can be loud and expensive. Enter the concept of eVTOLs: electric vertical take-off and landing aircraft. They are quiet, efficient and have zero carbon emissions. UK company Vertical Aerospace is set to build one of the world’s first certified passenger eVTOLs as early as 2024, and the 3DEXPERIENCE platform is helping their engineers and their supply chain design and validate composite structures as well as to find the optimal way of manufacturing each component from start to finish. They platform will also help when operations are up and running, particularly regarding components traceability.

Another challenge the world faces is finding a better way to monitor both the environment and infrastructure from the air, including checking on oil and gas pipelines and railways, observing fauna and flora in forests and carrying out large-scale surveillance over the sea. Could autonomous drones take over this task that’s traditionally done by space satellites? French company XSun thinks so. They’re designing, testing and showing how solar-powered, long-range drones can carry out these missions, and more. Its double-wing machines are economical to produce and run and offer a great range, high endurance and strong sustainability, while generating no carbon emissions. The 3DEXPERIENCE platform is helping the XSun team test everything from materials to aerodynamic performance, including figuring out how to add more solar panels on its wings.

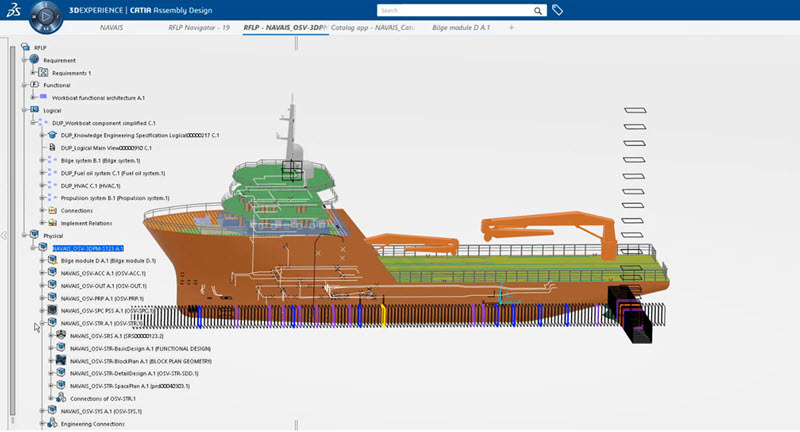

Digital and sustainable shipbuilding

Intense competition and the need for achieving sustainability goals is driving transformative approaches in shipbuilding.

The European shipbuilding industry is actively focused on employing new methods to maintain global leadership in complex vessels, while also making sustainability more integral to new projects. In close cooperation with more than a dozen partners and co-funded by Horizon 2020 (the biggest EU Research and Innovation program ever conceived) Damen Shipyards Gorinchem is coordinating the New Advanced Value Added Innovative Ships (NAVAIS) program to meet this objective. By June 2022, NAVAIS will develop guidelines and KPIs for low-impact ship design and operations, reducing or, preferably, eliminating emissions. They’re leveraging the 3DEXPERIENCE platform and a Model-Based Systems Engineering (MBSE) approach to help profoundly change how new shipbuilding projects are approached, moving from an engineering-to-order business model to an assemble-to-order business model. This calls for defining a modular design process and a library of modules that can be reused, helping to standardize production. The goal is to have shorter lead times, consistent quality, reduced design and production costs and improved supply chain integration, while still meeting clients needs. Bureau Veritas will simulates a vessel’s energy efficiency within the 3DEXPERIENCE platform.

Founded in 1865, CSSC Jiangnan Shipyard is one of China’s largest shipbuilding companies. They wanted to strengthen competitiveness and modernize processes, so in 2015, Jiangnan Shipyard selected the 3DEXPERIENCE platform to lead the digital transformation of the CSSC Group. One objective was to move from relying on 2D documents in the shipbuilding process and instead be paperless, making 3D models the core of design and production processes. Dassault Systèmes helped Jiangnan Shipyard to define, share and monitor KPIs based on typical use cases. The result: for its Haixun 160, Jiangnan Shipyard did not use a single piece of paper during design or construction. The project took just three months to build and assemble, with project teams no longer needing to look at often-complex 2D blueprints; instead, they could closely examine each detail directly on the 3D model, using a laptop or tablet to access all of the detailed information. Next up, Jiangnan Shipyard is looking to leverage virtual twins to help owners with maintenance throughout the ship’s lifecycle.