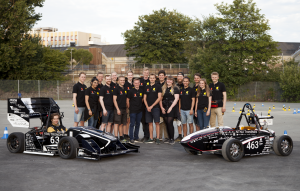

Revolve NTNU is a student organization that each year designs, manufactures, assembles and competes with a Formula Type race car in the worlds largest engineering competition for students: Formula Student. The organization is run as a small to medium business consisting of 70 members, with a board, and both marketing and technical compartments. We spoke to Jacob Hayes Vigerust, a team member focusing on gearbox design, to talk to us about this year’s project.

*Photos courtesy of NTNU.

Please describe why you chose this topic for your project.

The gearbox is a complicated assembly, which means that a string of technical challenges needs to be addressed. Formula Student is a competition but above all it is a platform for students to learn, and to learn as much as possible about a complicated system such as the gearbox is therefore ideal. Through the project I have studied machine element design, Finite Element Analysis, and design for manufacturing and assembly.

Describe how you executed the simulations.

With many interacting parts and different load scenarios, only rough estimations can be made by hand. To ensure a lightweight, but also reliable design, simulations were used extensively. Of key importance for the gearbox and the design of the gears is the amount of misalignment due to the high torque that is transmitted through the assembly. In an effort to optimize the design, Tosca Structure and Abaqus were utilized. The design space was first established in agreement with interacting systems. A topology optimization was then carried out on key components to minimize mass but maximizing stiffness, and thereby also minimizing gear misalignment. The optimization was done with an assembly of parts. This saved simulation setup time and gives an optimization that takes component interactions into account. The optimized result was then modified to a machinable design and a full assembly analysis was conducted to establish the amount of misalignment.

The gearbox, with an input speed of 20000 rpm, can also be prone to resonance. The system’s natural frequencies were therefore analyzed using Abaqus, and stiffness and mass were altered to avoid resonance in the frequency domains the gearbox is expected to operate in steady state.

Were there any key technical challenges you faced along the way? How did you solve them?

A key challenge was the definition of the many interactions between all the parts that make up the gearbox. This was solved by building up the model step-by-step, where more complexity was added in each step. The incredible “global contact” together with the comprehensive documentation and the step-by-step process led to a converged result of a complex assembly where confidence of the result could be assured.

What were the advantages of using simulation in your project?

In racing, weight and stiffness are of great importance. To optimize these performance parameters, simulation is key. Simulation is used extensively through every system of the car, to maximize performance while retaining confidence in reliability. Physical testing is expensive and time consuming, and when designing and building a whole new car each year, time is especially scarce.

Why did you choose Abaqus over other simulation products?

Abaqus was chosen due to its many capabilities combined with user friendliness. Abaqus, together with other Dassault Systèmes products, covers a vast range of Revolve NTNU‘s needs, and keeps it on one platform. It’s comprehensive documentation also helps with troubleshooting and learning new types of simulations in a fast and easy way.

Do you feel that learning simulation skills in University will provide you with an advantage in your career? Please explain.

With the fast development of simulation tools, I think it will become even more important in the industry. A good understanding of how to use these tools in a safe, accurate and innovative way will therefore be an advantage.