This post was originally published July 9, 2019.

The SIMULIA Learning Community is a rich resource containing valuable content, including access to documentation, learning resources and how-to videos, all open and free to the public. Get the entire paper from the article below by logging in.

Porous elastomeric materials are widely used in industrial and commercial applications, especially as shock-absorbers, dampeners, packaging material, etc. Often times these applications involve very large deformations of the material. From a product design and performance perspective, engineers are usually interested in the macroscopic response of these materials and their interaction with other components in an assembly. Appropriate modeling of the macroscopic mechanical response of these materials under arbitrarily large deformations is therefore the main requirement for engineering applications.

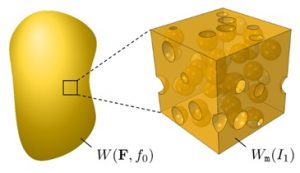

This document provides a summary of a remarkably simple and accurate constitutive model to describe the macroscopic elastic response of porous elastomers based on homogenization solutions. The model is very suitable for implementation in Abaqus using the UHYPER user subroutine. A schematic of a porous elastomer with spherical pores of monodisperse size is shown in Figure 1.

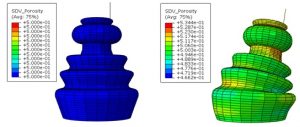

To demonstrate the applicability of the homogenization model and the associated UHYPER user subroutine, several examples of industrial interests with relatively simplified geometries are included in the document. For instance, Figure 2 shows the porosity of the material at the beginning (50% initial porosity, f_0=0.5) and the end of the analysis in a simplified automotive boot seal model. This model is modified from Abaqus | Example Problems | Static Stress | Displacement Analyses | Static and quasi-static stress analyses | Analysis of an automotive boot seal of the SIMULIA User Assistance 2019.

In the document, we begin by summarizing the main results in [1] and then describe some technical details regarding the implementation of the model in the UHYPER user subroutine. Finally, several examples of industrial interests are presented.

Reference: [1] Shrimali, B., Lefèvre, V., Lopez-Pamies, O. 2019. J. Mech. Phys. Solids 122, 364–380.

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW and more. The SIMULIA Learning Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Learning Community provides you with the tools you need to expand your knowledge, whenever and wherever.