This post is a continuation in a series about simulation on the 3DEXPERIENCE platform and some of the roles you can find there. This week we are focusing on the Additive Manufacturing Researcher role (MDA) and how it allows the user to conduct a physically realistic process-based simulation of a part to be manufactured by 3D printing. Missed the first post in this series? Don’t worry! It’s available here.

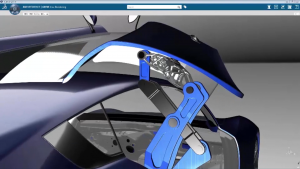

Additive Manufacturing Researcher allows the user to conduct a physically realistic process-based simulation of a part to be manufactured by 3D printing. The SIMULIA Additive Manufacturing Scenario app leverages information such as machine information, build environment, geometric support structures, slicing thickness and laser scan path data generated using the DELMIA Powderbed Fabrication app during the simulation. Realistic thermo-mechanical properties of materials are used which capture the phase transformation of materials during the printing process. In addition, accurate cooling and radiation between the different layers are captured by using the evolving free surface definitions to define convection and radiation properties. This leads to accurate prediction of part distortion. With the CATIA Virtual to Real Shape Morph app, the effects of this distortion on the original geometry can be corrected to provide a final part very close to the design intent. In-service loading of as-printed parts including residual stress history can be conducted to validate load capacity, flexibility, and service life. Additive Manufacturing Researcher is fully integrated with the CATIA Functional Generative Design app and the DELMIA Powder Bed Fabrication app to provide an end-to-end solution to additive manufacturing part design. Additive Manufacturing Researcher is an Extension Role for the following:

- Mechanical Analyst (SMU)

As part of the 3DEXPERIENCE Simulation portfolio, Additive Manufacturing Researcher sits on top of the Dassault Systemes V+R Process Management solution with next-generation Simulation Process & Data Management (SPDM) values enabling all simulation activities, models, process data, and results to be linked, traced, updated, and re-used with ease by all impacted users.

ROLE HIGHLIGHTS • Physically realistic simulation of 3D printing of parts including laser scan paths, material deposition & solidification, thermal distortion & residual stress, and support structures • Allows powder bed, polymer extrusion, and direct energy deposition (plus user defined) manufacturing process simulation • Offers a high level of automation and guidance to allow the user to easily setup complex simulations • Provides an easy to use experience on top of the sophisticated technology of the Abaqus solver while allowing customization for more advanced users • A guided user assistance panel provides a step-by-step workflow to set up a simulation • Uses part build information, automatically set build times and populate supports for some features

ROLE BENEFITS • Seamless integration to design and manufacturing • In-built simulation best practices to allow usage by additive experts • Automatically applies settings to conform to additive manufacturing software simulation best practices • Process-level, Part-level and build-level simulations in a single environment for metals or polymers • Reduce residual stress and distortion in completed parts • Increase dimensional accuracy • Optimize part orientation • Minimize print time and material usage • Post-processing methods for build plate removal and heat treatment • In-service performance validations of functional part

Don’t miss our next post in this series where we introduce the Mechanical Analyst (SMU) role!