This post was originally published in March 2021.

Recently, a massive winter storm swept across the United States, causing pileups of snow and ice, well-below-freezing temperatures, high winds, and, as a result, power outages. The hardest-hit state was Texas, which experienced outages that, in some cases, lasted for days. The crisis drew many reactions from across the country – one which, unfortunately, was to issue a blanket criticism of clean energy as some of Texas’s wind turbines were shut down during the storm.

These criticisms are ill-founded for several reasons. One, less than a quarter of the state’s energy is generated by wind turbines, and responsibility for the power outages falls more heavily on the failure of traditional fossil fuel plants. Two, the power losses from the wind turbines that were shut down were partially offset from wind farms elsewhere. Three, plenty of much colder climates are supplied with wind energy with no problems at all; turbines can operate in conditions as low as -30ºC (-22ºF) if necessary

That being said, there are measures that can be taken to improve Texas’s wind turbines and make sure they stay up and running if such a storm were to happen again. Severe winter weather like what happened earlier in February is highly unusual in Texas, so the turbines were not specifically designed to handle it.

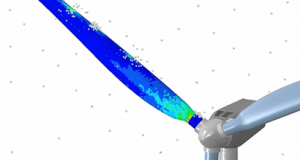

There are two main cold-weather issues that can affect wind turbines. One is related to ice buildup on the blades, which can decrease power generation. The ice accretion process as well as its resulting aerodynamic losses caused can be simulated and analyzed with SIMULIA PowerFLOW’s high fidelity CFD solver. Heating elements can also be installed to eliminate ice buildup and prevent lubrication grease from freezing. In addition, the area in which falling ice can be thrown must be calculated for safety reasons; this can potentially be done with software like SIMULIA Simpack.

It is more important than ever to invest in clean, renewable energy sources rather than placing blame on them. Scientists have argued that winter storms like the one that affected Texas are likely due at least in part to climate change, in particular the heating of the Arctic, which is causing the jet stream to shift and blast cold air into places where it normally does not travel.

Wind energy is one way to potentially slow climate change, along with other renewable energy sources such as solar and hydro power. Manufacturers of wind turbines face several challenges, however, such as a competitive market, short development cycles, diverse regional regulations, and expensive physical test procedures.

SIMULIA offers solutions to several of these problems. Simulation provides insight into any design at any level of detail, and SIMULIA’s multibody simulation tools in particular can result in significant cost savings. Its fluid simulation offerings can help optimize turbine blades to improve performance and reduce noise to meet or exceed regulatory requirements, and its best-in-class composite layout design and structural simulations are capable of increasing power without increasing loads.

SIMULIA’s Lattice Boltzmann CFD software is 100% repeatable, as opposed to wind tunnels which have poor repeatability. Other advantages over wind tunnels include a better understanding of physics as well as 10 times more design iterations. Software such as SIMULIA Simpack can help engineers decrease loads and reduce mass and dimensions, resulting in lower costs.

Perhaps the most important function of simulation is the avoidance of risk. With SIMULIA tools, engineers can accurately natural frequencies with higher fidelity in order to avoid critical resonances that result in faults and down time.

You can learn more about SIMULIA’s wind industry solutions in the presentation “Pushing the Boundaries of Wind Turbine Engineering,” given at last year’s 3DEXPERIENCE Modeling and Simulation Conference by Steve Mulski, SIMULIA IPS, Industry Process Expert – Wind Energy Executive. The presentation can be accessed here. Please note that you will be asked to log in; once you have done so, please click or copy and paste the above link a second time to be redirected to the correct location. In addition, you can read the article “Fluid-Structure Coupling for Wind Turbine Rotors” by logging in to the SIMULIA Community here.

Additional resources include the following available-on-demand e-seminars:

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.