Emerging Energy Systems and Their Challenges

Engineers are not just improving existing designs. They are reinventing how entire energy systems are developed and delivered. This reinvention brings new engineering challenges across several breakthrough technologies.

- Fusion Energy: Making fusion commercially viable relies on solving extreme engineering problems. Materials must survive intense neutron bombardment. Cooling systems must manage severe thermal gradients. Reactor geometries must balance safety, stability, and scalability. Simulation allows engineers to explore these conditions virtually, which reduces reliance on physical prototypes.

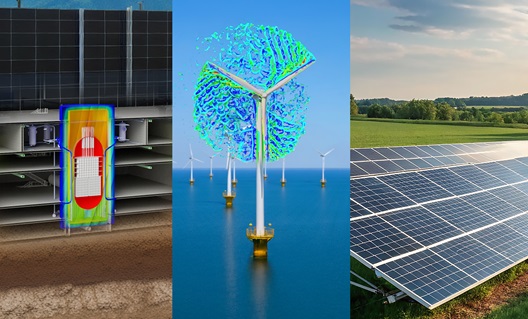

- Small Modular Reactors (SMRs): SMRs and Generation IV designs are safer, more flexible alternatives to traditional nuclear reactors. They adapt better to regional grids and variable demand. However, innovation raises questions about manufacturing simplification without compromising safety. Simulation answers these questions early, giving engineers confidence to iterate faster and achieve regulatory compliance.

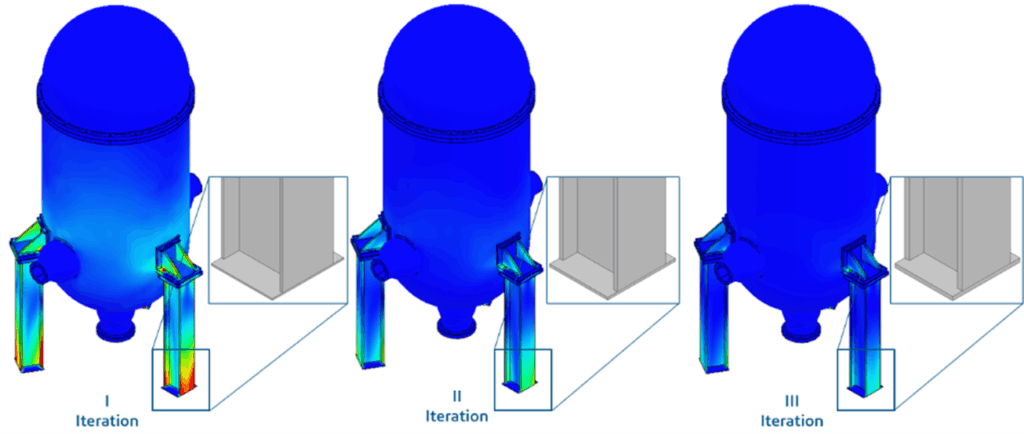

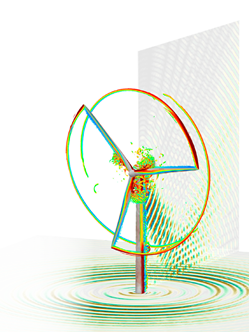

- Offshore Wind Power: The ocean is a difficult engineering environment. Developers must account for wind variability, wave forces, and turbine fatigue. Simulation makes it possible to model these conditions in advance. Teams can test system responses and fine-tune performance strategies before installation, reducing cost and risk. Learn more in our latest blog.

- Hybrid Energy Systems: These systems combine technologies like wind-powered electrolyzers for green hydrogen. They bring together multiple domains, including mechanical, electrical, thermal, and fluids. Multiphysics simulation lets engineers model these interactions as a complete system to guarantee reliability and efficiency.

Key Engineering Hurdles in the Energy Transition

Engineering teams driving the energy transition navigate a range of demanding constraints. They must move fast without cutting corners.

- Faster Time to Market: Development timelines are shrinking. Expectations for quality, reliability, and safety remain unchanged.

- Evolving Regulations: Safety and environmental standards are constantly updated. Teams need capabilities that support traceability and certification at every stage.

- Economic Constraints: Volatile supply chains and rising material costs demand cost-effective solutions for high-risk environments.

- Interdisciplinary Complexity: Today’s energy systems span multiple physics. Designing across these boundaries requires seamless integration and a systems-level view.

- Infrastructure Scale-up: Adding new energy capacity means upgrading grids, storage, and distribution networks. These large-scale projects are expensive and time-intensive.

Simulation provides a solution. High-fidelity testing in a virtual environment reduces uncertainty and improves design outcomes. It removes the high costs and risks of physical prototyping.

The Power of Simulation and Virtual Twins

Simulation provides a virtual environment to test, iterate, and validate ideas before making a physical prototype. Whether optimizing a wind turbine blade or analyzing heat transfer in a reactor core, simulation allows engineers to explore ideas quickly and make confident design decisions.

Virtual twins elevate this capability. A virtual twin is a precise 3D model that combines geometry, data, and physics. It captures the behavior and performance of an energy asset over its entire lifecycle. Advanced simulation integrates real-world data to show how the asset will respond under different conditions. This live link between physical and virtual worlds allows teams to monitor, optimize, and manage energy systems. It offers predictive insights that help engineers make better decisions.

For energy providers, virtual twins offer several advantages:

- Lower Risk: Teams can test ideas virtually before construction, reducing rework and investment risk.

- Smarter Integration: Engineers can simulate how renewables, storage systems, and grids will interact under different load conditions, improving system reliability.

- Faster Planning: Operators can anticipate how transmission networks will perform under future scenarios, making long-term planning more proactive.

This approach empowers teams to explore ambitious designs with more confidence. Energy innovators are already using these methods. NAAREA uses simulation to evaluate its new micro-modular reactors, feeding real-world data into a virtual twin to test safety and performance. Similarly, Envision Energy models entire wind turbine systems to fine-tune designs and improve reliability. LM Wind Power applies advanced aeroacoustics modeling to design quieter, more efficient turbine blades without costly field tests.

MODSIM: Unifying Design and Simulation

Modern engineering projects are too complex for traditional, linear development. Unified CAD modeling and simulation, or MODSIM, offers a practical way forward. MODSIM eliminates silos between design and simulation. Teams collaborate on one platform, designing and simulating simultaneously on a common data model.

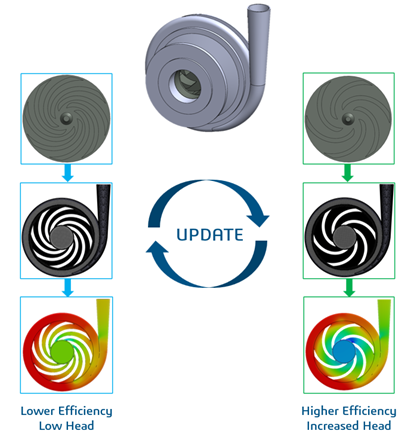

Simulation on the 3DEXPERIENCE platform is powered by respected and deployed solvers (e.g., Abaqus). MODSIM establishes a continuous feedback loop, allowing engineers to build geometries, mesh parts, and apply test conditions without requiring file exports. If a design changes, the simulation updates automatically. This integrated loop supports rapid design exploration. Teams can quickly weigh trade-offs and improve outcomes without slowing development.

This unified approach transforms collaboration by eliminating manual handoffs between designers and analysts. By connecting CAD and simulation with program management in one environment, the 3DEXPERIENCE platform acts as a single source of truth. Decision-makers can trace every design choice back to its performance data. This lowers the barrier for simulation adoption. It empowers designers and engineers to simulate directly within SIMULIA without needing deep analyst involvement. Ultimately, MODSIM helps companies shift to a more agile, digitally connected engineering process.

Build a Sustainable Future

The energy sector is changing rapidly. SIMULIA helps companies keep pace by combining advanced simulation with flexibility and scale. By integrating simulation into daily workflows, engineers can test ideas early and resolve issues faster. Cloud-powered collaboration on the 3DEXPERIENCE platform provides access to simulation anytime, anywhere, with scalable High-Performance Computing (HPC) when needed. This unified approach delivers better products, faster.

By unifying CAD, simulation, and data in one virtual environment, we empower energy innovators to think holistically and design with purpose. Together, we can build the systems that will power a sustainable, resilient future.

Ready to accelerate your innovation? Contact an expert today to learn how simulation can transform your engineering workflows.

Keep reading:

- The Power of Simulation in Sustainable Energy Systems Innovation: https://discover.3ds.com/accelerating-sustainable-energy-innovation-simulation

- A Framework for Wind Turbine Noise Reduction: /brands/simulia/framework-wind-turbine-noise-reduction/

- Optimize Your Wind Turbine Engineering: https://discover.3ds.com/wind-turbine-simulation-for-sustainable-energy

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.