This post was originally published in July 2020 and has had several updates since then.

One of the automotive industry’s greatest hopes for the future is the electric vehicle. As more and more electric vehicles hit the road, the benefits add up: less dependence on fossil fuels; fewer greenhouse gas emissions; overall greener and more economical travel. Electrifying transportation isn’t as simple as just flipping a switch, however. Designing an electric vehicle is a complex process that differs greatly from designing a traditional vehicle. The engineers who were developing internal combustion engines had about a century to make the technology work perfectly, but the engineers who are working on the electrification only have a decade to design an electric vehicle that can match or exceed the performance of a traditional vehicle. Electric vehicle engineers must integrate both, the battery along with the electric drive, into the vehicle.

The electric drive is a complicated system whose parts need to work together effectively and efficiently. These include the gear box and electric machine, which need to be designed carefully to avoid over-designing. Over-designing leads to excess material, weight and cost and system engineering helps to precise and balance targets like maximum torque, power and speed, in the context of the whole vehicle.

The design must fulfill requirements for performance, efficiency, thermal, noise and vibration, etc. It is key to include multi-disciplinary design explorations and optimizations in order to reduce the required time of the development cycle. Once the many components of the electric drive have been implemented, their performance must be verified against the targets defined by Model-Based Systems Engineering, or MBSE.

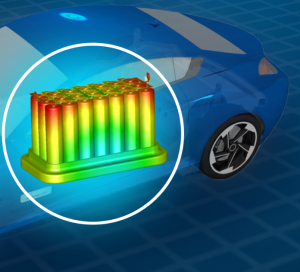

In addition to the electric drive, the battery is a vital part of an electric car – and it’s not simple to design, either, especially when considering temperature. Batteries are akin to humans in that they perform best within a certain range of temperatures. If a battery’s temperature is too high or too low, it can result in lower vehicle range or shortened battery life.

Batteries involve multiple and connected physics, making them tricky to design, but Dassault Systèmes is working on a solution that connects mechanical and system design, materials and chemistry modeling, and performance assessment of battery cells, modules and packs.

When a battery is evaluated along with the electric drive on a vehicle, engineers and manufacturers can get a real idea of the performance and range of the battery rather than relying on a test at a test cell. The battery performance can be tested with real load on the battery, enabling an accurate picture of how it will perform in the real world.

Learn more about the future of electric vehicles and how simulation and SIMULIA technology helps engineers overcome challenges and innovate sustainable designs by visiting the Electric Vehicle topic in the SIMULIA Community.

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, SIMPACK, CST Studio Suite, XFlow, PowerFLOW, and more. The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.