Executive Summary

Demand for hydrogen production is increasing significantly and is a key part of the decarbonization mission and transition of energy initiatives. Hydrogen has significant potential as a means of storing and transporting energy – for example, as a fuel source for vehicles or as an alternative to natural gas in heating systems. Green electricity can be converted directly into hydrogen through electrolysis. In order to be economically viable, the cost of green hydrogen needs to decrease, and its storage density needs to increase.

In this blog post, we explain how predictive modeling and simulation (MODSIM) is helping equipment manufacturers develop next-generation hydrogen technology, including electrolyzers and storage tanks. Using MODSIM, hydrogen technology can be developed faster, analyzing performance on a virtual twin. Concepts can be tested, and problems can be identified without the time and cost of building and testing a physical prototype. Designs and materials can be optimized automatically. Integrating MODSIM into the design process cuts development costs and accelerates time to market.

What is Green Hydrogen?

Hydrogen is often talked about as a form of green energy, but its environmental impact depends on how it is produced. The different forms of hydrogen production are often labeled with colors. Blue and gray hydrogen are produced from natural gas by steam methane reforming, for example, while black or brown hydrogen is produced from coal. Most hydrogen is currently produced with these methods, which results in carbon emissions.

Green hydrogen refers to hydrogen produced using energy from zero-carbon and renewable sources. This is sometimes extended to include pink hydrogen (hydrogen produced with nuclear power) and yellow hydrogen (which can refer to hydrogen produced with solar energy or with grid electricity from a mixture of sources). All of these forms of hydrogen are produced by electrolysis.

Electrolysis is a chemical reaction where an electrical potential applied to some substance splits the molecules and produces reaction products at the electrodes. To produce hydrogen, a voltage is applied to water. The H2O molecule splits and hydrogen gas forms at the anode while oxygen forms at the cathode.

Electrolysis is a very clean process, and if a green electricity source is used, the process results in essentially no pollution. When the hydrogen gas is burned or converted back to electricity, hydrogen and oxygen reform to produce water.

Hydrogen as a fuel has several potential applications. Vehicles can use hydrogen in fuel cells to generate electricity, while hydrogen can be added to the natural gas supply in order to reduce the carbon emissions from gas-powered heating. Hydrogen also has various applications in industry and it can potentially be used to store excess energy produced when wind or solar output is higher than demand.

For the hydrogen economy to mature, both the production, transport, storage and consumption of hydrogen need to become more efficient, and green hydrogen needs to displace more polluting forms. Simulation is helping hydrogen engineers to develop new technology and optimize the entire hydrogen ecosystem, from production to consumption.

What is MODSIM?

Traditionally, modeling and simulation were seen as separate disciplines and were performed by different, siloed teams. Analysis could only start after the design was complete, by which point the impact of design decisions was baked in. Correcting problems found during analysis or testing could be expensive and time-consuming. Integrating modeling and simulation (MODSIM) closely throughout the development cycle accelerates design and reduces risk.

Shift-left testing–performing analysis earlier in the design cycle – with simulation allows designers to see the impact of their design choices and make informed trade-offs between design parameters. They have access to the insights of simulation even at the concept stage, allowing them to optimize designs and explore different options before committing to a specific design choice.

MODSIM breaks down the silos between teams and provides everyone with a single source of truth. Here, requirements, design geometry, simulation results and test data are all brought together traceably in one place on a “virtual twin” of the real system.

MODSIM also democratizes simulation. Pre-defined workflows and templates for common hydrogen engineering processes allow designers to use simulation independently and access it whenever needed. Less expertise is needed and users can get started with simulation faster. We have listed various MODSIM workflows available on the Dassault Systèmes 3DEXPERIENCE platform for designing hydrogen systems.

Electrolyzers

Electrolyzer Performance and Efficiency

Proton exchange membrane (PEM) technology is a promising approach for efficient electrolysis. Compared to other approaches, PEM results in high current density throughout the water, and prevents the formation of gas bubbles which reduce efficiency.

Non-uniform temperatures can reduce efficiency and also increase system fatigue. PEM engineers need to design for optimal operating temperature and pressure. Optimizing the bipolar plate is a multi-physics problem with electrochemistry, structures, fluid and thermal simulation requirements

In a MODSIM workflow, the simulation model of the bipolar plate can be extracted from the full stack model. With a few clicks, the coolant channel can be meshed and the properties of the coolant and the flow set up can be defined. Simulation with a conjugate heat transfer solver then calculates the performance of the cooling system. If any issues are identified, an automatic parametric design study can be used to find a more optimal design. The optimized geometry is then transferred back to the full system model.

This entire workflow is available within the 3DEXPERIENCE platform. Design apps from CATIA and simulation and parametric design study apps from SIMULIA are integrated into a continuous process. Designers have access to simulation results and optimized geometry within a common platform, giving them the information needed to develop an efficient electrolyzer system faster and with less risk.

Electrolyzer Manufacturing

The bipolar plate accounts for 45% of the cost of a PEM electrolyzer system, and significantly reducing the cost is crucial to commercializing the technology. Implementing simulation during the design process guides engineers to make the right decision on topics such a materials and manufacturing process.

MODSIM on the 3DEXPERIENCE platform offers parametric model design integration between the concept design and the final design for manufacturing. Simulation can reveal the impact of manufacturing variations – for example, thickness accuracy – and what-if studies can compare different manufacturing setups.

Structural simulation can model the punching process used to manufacture the ridged bipolar plate. This is usually a multi-stage simulation wherein the initial punch stage pushes the blank into the die and in later stages punch gradually performs the final stretching of the sheet. Parametric design space exploration can be used to change the geometry and manufacturing tolerances in order to get optimum bench radius to get optimum thickness reduction.

Storage Tanks

At standard temperature and pressure, hydrogen gas has a low energy density, so it needs to be stored at very high pressure to compete with fossil fuels and batteries. On vehicles, the tank needs store hydrogen very at a very high – pressure up to 70 MPa (700 bar) to provide adequate driving range- and also needs to be lightweight when on mobile vehicles. This has led to the use of wound filament composite materials. Abaqus solver technology on the 3DEXPERIENCE platform can predict the structural behavior of these complex materials accurately with nonlinear mechanics capabilities.

Tank Strength and Stiffness

A tank needs to maintain its integrity in the event of an accident, such as a drop or a crash. Hydrogen tank design must meet international standards such as DIN EN 12245 and ISO 11119-3. The physical testing needed for these standards can be time-consuming, delaying product development and making optimal designs hard to achieve. Simulation can accelerate the process by replicating physical tests such as drop testing virtually.

The SIMULIA and CATIA development teams have been working on a plug-in for Abaqus that can generate detailed simulation models of wound filament composite materials. A structural simulation of the tank reveals the stress, strain and displacement of the tank material, revealing potential points of failure. Simulation demonstrates the impact of changing the properties of the material, such as the winding angle, helping engineers to find the best design for their requirements. Both static and dynamic scenarios – such as a dropped tank – can be analyzed.

Tank Filling

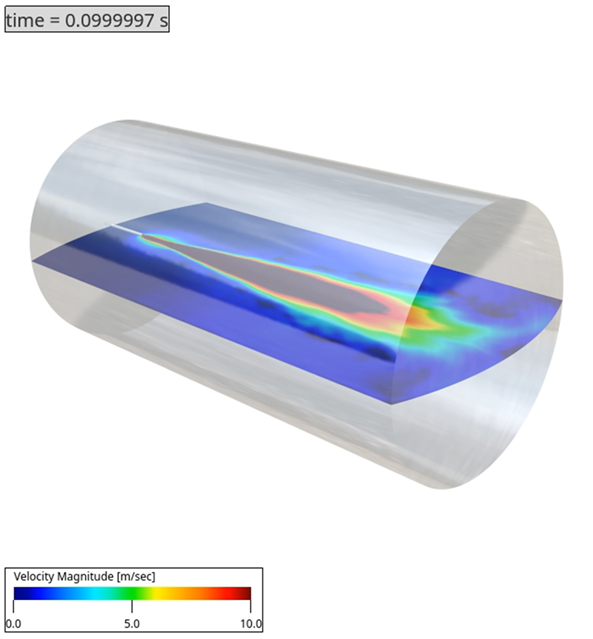

The physical gas laws mean that as a hydrogen tank fills and its pressure increases, its temperature rises quickly. Extreme high or low temperatures will affect the mechanical performance of the materials, potentially impacting safety.

Computational fluid dynamics (CFD) simulation can model the tank filling process and calculate temperatures. Real gas modeling accurately captures the high pressure and temperature changes in the tank. The impact of different materials can be analyzed, as can the effect of external weather conditions. Compared to physical testing, simulation can deliver results for multiple design variants quickly and cost-effectively.

Analyzing the Entire System

While this blog post has focused on simulation with the physics simulation tools from SIMULIA, other aspects of hydrogen production can be modeled with other approaches. Going down to the nanoscale, pipes can be studied at the molecular level using technology from the BIOVIA brand of Dassault Systèmes in order to understand the welding process and the microstructures that form, through which hydrogen can enter and potentially weaken the metal. At the other end of the scale, the Dymola system simulation tool from the CATIA brand can be used to simulate processes across an entire hydrogen plant.

All these tools are available within the Dassault Systèmes portfolio and are brought together by the 3DEXPERIENCE platform. This provides a common platform for collaboration and data sharing between users and connects different products in a common workflow. For information or entire solution for sustainable hydrogen, see our whitepaper about predictive modeling and simulation for the hydrogen ecosystem.

Conclusion

Demand for green hydrogen is growing as part of the decarbonization of society. The production and storage of hydrogen needs to be made more efficient in order to be cost-effective and competitive with other solutions. Simulation allows engineers to analyze the performance of equipment such as electrolyzers and storage tanks during development. The integrated modeling and simulation (MODSIM) solution from Dassault Systèmes brings together design and analysis tools so users can identify risks and optimize performance during the early stages of development and bring products to market sooner.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.