Introduction

From the touchscreen of our mobile phones, to controlling smart household appliances and purchasing a ticket from an automated ticketing machine in the metro station, we interact with a multitude of touchscreens on a daily basis. The ease of use of such screens and the intuitive response that they give back is all down to the quality of the detection of our finger as it glides across the surface and taps the screen.

There are various different types of sensors that have been developed over the years and capacitive sensors remain the most widely used ones when it comes to touchscreen technology. These capacitive sensors are the most suited ones to detect the presence of a human finger by its electromagnetic properties and allow multiple layers of glass and plastic materials between the finger and the sensor itself.

Designing Capacitive Sensors for Touchscreen Applications

There are a number of aspects that must be considered in the design of such a sensor. When it comes to the efficiency of such a detection system, there are two main considerations: the accuracy of detection (especially when screens become smaller and the resolution increases) and the speed of detection.

Smartwatch Capacitive Sensor Design and Modeling

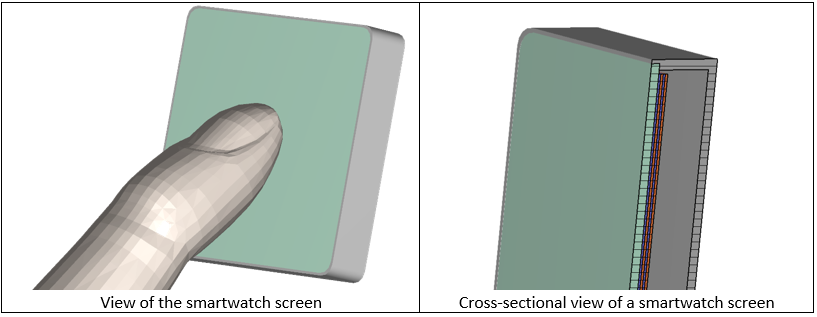

The smartwatch screen contains various different layers, which provide strength and act as the medium for displaying the information. The screen assembly is housed in a case and the sensors lie behind the layers of the screen.

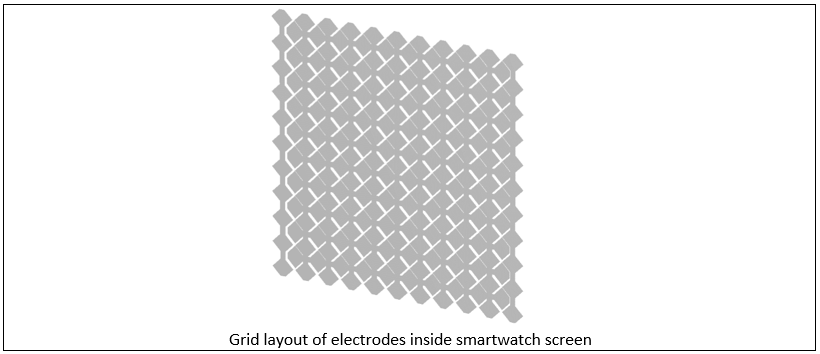

The sensor array is laid out in a grid and consists of rows and columns of electrodes, which can be controlled independently.

A known capacitance exists between each row and column in a grid. When a human finger approaches the grid, the capacitance of these rows and columns changes.

Capacitance Analysis of the Sensor without the Finger Present

The individual rows and columns of the grid are excited sequentially at small intervals.

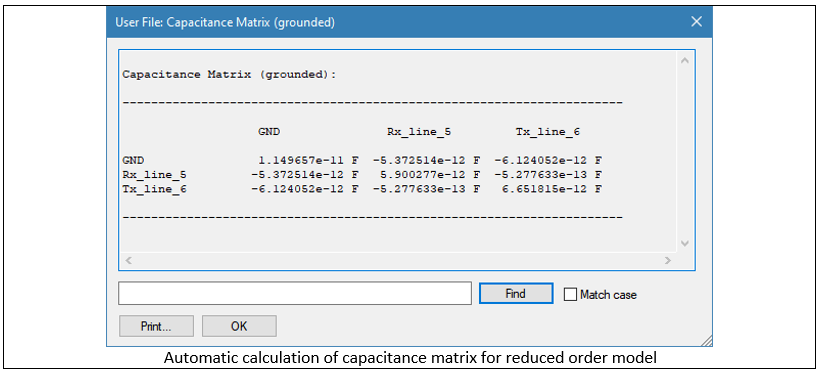

The software automatically calculates the capacitance between the rows and columns at different potentials and the ground using a series of electrostatic analyses. The resulting capacitance matrix fully characterizes the electrostatic behavior of the grid and can be used as a reduced-order representation of the FE model during circuit simulations.

Detecting a Finger with a Capacitive Sensor

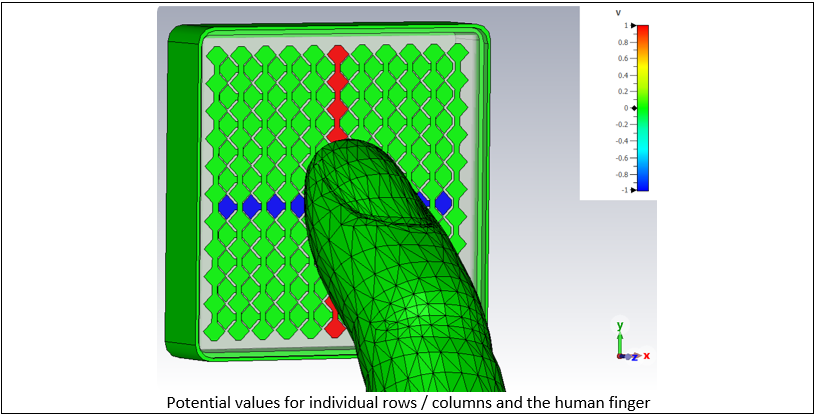

CST Studio Suite offers a library of human models, including models of human fingers. The import and placement of these models into the model of the smartwatch is straightforward. Normally, the finger potential is the same as ground. The effect of the finger on the electric field distribution and the capacitance matrix can be incorporated in the model.

A parametric study has been performed for eight different positions of the finger, at varying distances from the surface of the screen (see image below). The change in capacitance for individual parts of the sensor grid is calculated. This calculation defines a sensitivity range for detection. As expected, the effect of the change in capacity is highest when the finger is closest to the screen and its effect diminishes as the distance increases.

Optimization of the Capacitive Sensor Detection Circuit

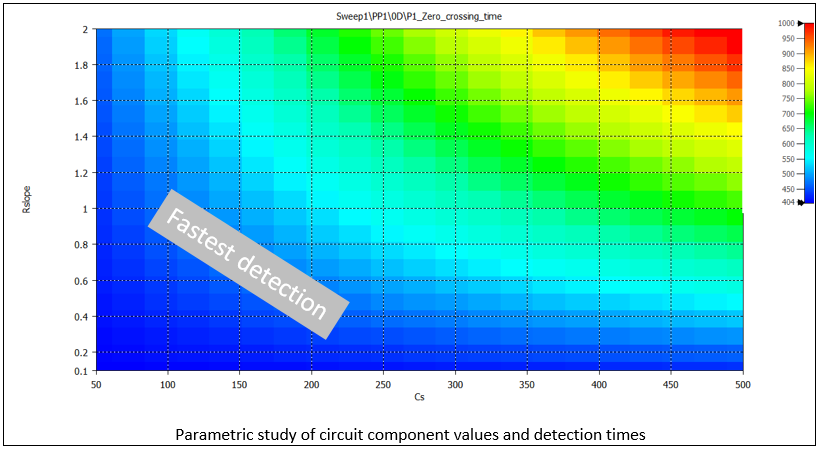

Once the capacitance characteristic is obtained for the circuit without and with the finger, the next step is to improve the detection speed by optimizing the detection circuit.

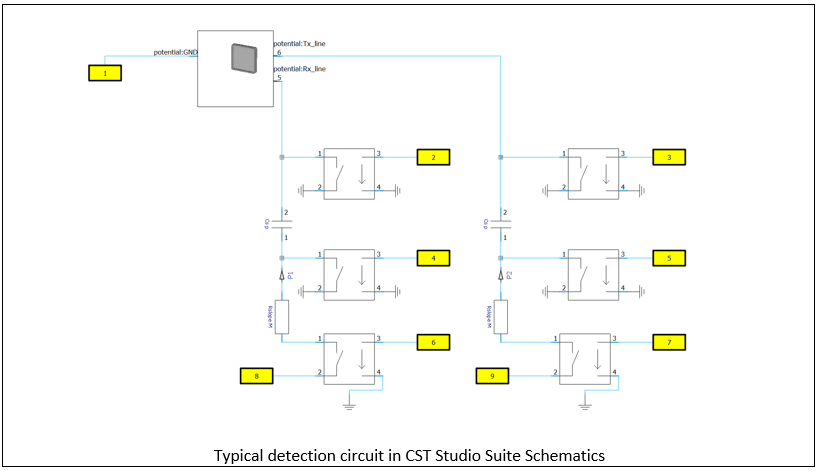

Each row and column of the sensor grid connects to a voltage-controlled switch, allowing for the sequential excitation of the entire grid many times per second. The optimization of the circuit components ensures the fastest possible response time from the sensor array which corresponds to a real-time feel for the user to the movements of their finger.

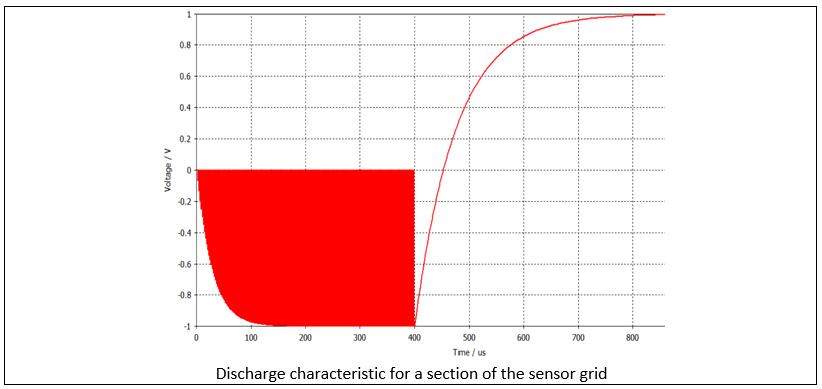

The response of the circuit is measured by the voltage drop across the circuit components. The faster the voltage drop, the quicker the detection of the finger position and the better the temporal resolution of the sensor. In the image below, we can see the voltage characteristic at the position of the probe P1. The circuit is charging for a given amount of time, after which the connection to the supply is interrupted and the circuit is allowed to discharge. The detection is done at the zero-crossing point of the probe signal.

The CST Studio Suite Schematic tool allows for rapid circuit simulations that include the representation of the smartwatch and finger finite element (FE) model by their equivalent capacitance matrix, previously calculated from a series of FE solutions for different finger positions.

Very fast optimization studies can be performed to optimize the values of different circuit components (for example resistors and capacitors) to obtain the fastest detection time. The optimization can be performed in a matter of seconds or minutes, as it does not require rerunning of any new finite element solutions.

Manufacturers of such touchscreen devices can therefore quickly optimize their capacitive detection layout for any new types of geometric outline and screen manufacturing process and ensure the best detection characteristics for the most realistic response from their device.

Conclusion

Touch screens are becoming more and more common place in all types of consumer devices. As the pressure to reduce cost and improve detection accuracy is growing, capacitive sensors are becoming the go-to solution for these devices.

CST Studio Suite offers the complete set of capabilities to model and optimize such capacitive sensors. It’s state-of-the-art finite element solver, circuit simulator, and human models offer to the designer a quick and easy way of validating and improving their designs. The number of prototypes can be significantly reduced and any potential issues with the accuracy and latency of the detection can be addressed at the very early stages of design, preventing the costly process of late stage redesign.

Interested in the latest in simulation? Looking for advice and best practices? Want to discuss simulation with fellow users and Dassault Systèmes experts? The SIMULIA Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Community provides you with the tools you need to expand your knowledge, whenever and wherever.