This article was first published in the first edition of REVEAL Magazine in September 2019.

Academic Perspectives on Sustainability

Researchers, professors, students and others working in academia are at the forefront of shaping the future of our world and in many cases, they are using simulation, design and engineering to do so. In this section of REVEAL Magazine, we hear directly from academics about their perspective on important trends and topics and learn about some of the work they are doing to create the future.

This edition of REVEAL focuses on sustainability and we ask academics to tell us about how sustainability plays a role in the work that they do across various industries including additive manufacturing, life sciences, transportation and mobility, and renewable energy.

TIMOTHY W. SIMPSON, PHD

Paul Morrow Professor of Engineering Design and Manufacturing at the Pennsylvania State University

As an expert in the field, what do you think additive manufacturing’s role can be in creating a more sustainable world? Do you think it will replace other forms of manufacturing completely or simply supplement existing processes?

While the design freedom enabled by additive manufacturing (AM) is exciting, we often forget about the material freedom associated with “printing” parts layer-by-layer. With AM, we only add material where necessary, reducing the scrap and waste associated with many traditional manufacturing processes. In the aerospace industry, this is called the buy-to-fly ratio (amount of material purchased versus material in the part), and AM can help reduce this from upwards of 10:1 to 2:1 or 1.5:1 or better. While we are not at 1:1 yet, we are getting closer as we get better at designing for AM.

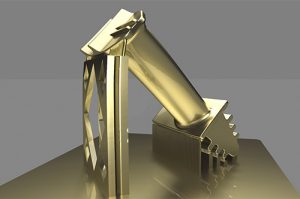

By combining AM’s design and material freedoms, we can create lightweight structures that maximize material utilization using lattices, topology optimization, biomimicry, and other generative- design tools. Such structures use material more efficiently and require less build time, which saves energy. Improving material utilization may also make a more expensive material viable with AM. Better materials usually last longer, which means components do not need to be thrown away or replaced as frequently, both of which are better for the environment.

AM can also enable “manufacturing on demand:” make only the parts you need, when you need them, where you need them. This means less waste, less inventory, less transportation, etc. provided we can work through the regulatory, legal, and cybersecurity issues that often plague AM.

Finally, just because we can “print” something doesn’t mean we should. Traditional processes have their strengths, and AM isn’t going to replace traditional manufacturing. In fact, AM often needs other forms of manufacturing to make end-use parts; so, the real question is: how do we combine both to promote global sustainability efforts even more?

For more information: http://www.cimp-3d.org

SIMULIA offers an advanced simulation product portfolio, including Abaqus, Isight, fe-safe, Tosca, Simpoe-Mold, SIMPACK, CST Studio Suite, XFlow, PowerFLOW and more. The SIMULIA Learning Community is the place to find the latest resources for SIMULIA software and to collaborate with other users. The key that unlocks the door of innovative thinking and knowledge building, the SIMULIA Learning Community provides you with the tools you need to expand your knowledge, whenever and wherever.