This is Part 2 of our 12-part blog series based on the LNS Research eBook, “Forging the Digital Twin in Discrete Manufacturing: A Vision for Unity In the Virtual and Real Worlds”.

In Part 1 we explored the definition of a Digital Twin and explained how Dassault Systèmes’ vision of the 3DEXPERIENCE twin goes further: by breaking down data silos, manufacturers can analyze information within its complete context and create accurate virtual models for experimentation. Now let’s explore today’s possibilities being driven by Digital Twin technology.

Today’s Possibilities

There’s nothing new about Digital Twins; we saw the first physical/virtual presentations as early as 2002. The concept wasn’t an instant success due to complexity and the inability to handle the information required to deliver real value. Like many new concepts and approaches used in industry today, the Digital Twin has hugely benefited from the advent of the Industrial Internet of Things (IIoT), Industry 4.0, and, in general, the maturing of a plethora of other technologies around the same time.

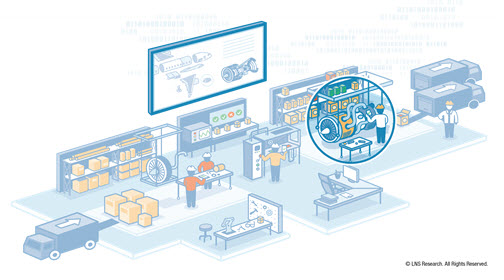

The Digital Twin relies on several leading technologies delivered by the IIoT: Big Data analytics, connectivity and application development, business process management, and on top of these, maturing technologies in the manufacturing world including:

- Smart automation and IIoT-connected control

- Product lifecycle management (PLM)

- Three-dimensional computer-aided design (CAD)

- Digital simulation

- Manufacturing process management (MPM)

- Manufacturing operations management (MOM) software

- Virtual reality and augmented reality (VR/AR)

These technologies combine in many different ways to support digital twins for discrete manufacturing — a product twin and a twin of the process used to make it. Although some of the related technologies have been around for a long time, the advent of more powerful computing and connectivity allows the Digital Twin to take on more fidelity and richness and become more like a virtual identical twin.

An identical twin is like a Turing test in computer intelligence in that a human (or even a system) cannot distinguish between the twin and the real system. Today identical twins hardly exist and certainly not for complex systems of systems. As technology evolves, accuracy will tend towards the identical twin.

EXALEAD Commentary:

The first generation of Digital Twins were limited to present on a computer the “CAD view” in 3D of the physical asset, mirroring the values acquired by the sensors connected to the physical asset. This use case requires the as-designed “CAD view” that reflects exactly the as-is view.

This situation applies for product manufacturers who are maintaining their “CAD views” aligned with the assets they deliver. But a complete and accurate “CAD view” of a manufacturing plant, a production line or a process plant is almost never the case.

Building a Digital Twin for brown fields is a huge challenge, as it requires reverse engineering in order to rebuild the “CAD view” and to federate data stored in many different IT systems.

“Do I really need to build first the full 3D view of my production line or my plant before I can expect to get benefits out of my Digital Twin?”

Dassault Systèmes allows users to address the digital transformation from a different angle, building the facets of the 3DEXPERIENCE twin progressively and in an iterative way rather than with a “big-bang” approach.

It is important to first to break down the silos between systems hosting the data and organizations where people have a limited view of those data. Sharing a common understanding about the assets is key in order to avoid taking contradictory actions or decisions in operations.

EXALEAD on the 3DEXPERIENCE platform is connecting the dots between systems, organizations and assets by providing decision-making cockpits that are surfacing information within one single view , hosted in the different IT and OT systems available to the users.

Once information is made available to the community of users from one single place, they can collaborate and contribute to the data cleansing process with less effort. Through this closed-loop feedback, continuous quality improvement is assured, reducing errors. Revealing consistent information in the context of the 3D enables users to understand diverse situations.

A 3DEXPERIENCE twin can present a 3D hybrid view of the asset as a mix of “CAD views” merged with points of cloud?. This combination provides the most appropriate views for the users. Playback capabilities allow users to learn about past situations. The will gradually capitalize on the knowledge and identify areas of improvement to prevent errors or unplanned downtimes.

EXALEAD on the 3DEXPERIENCE platform is providing smart analytics, helping non-experts to investigate problems by searching for similar situations that might have occurred in the past.Machine learning techniques are used to reproduce the methods experts usually follow when they have to solve a problem.

The EXALEAD search engine allows users to enter in natural language any kind of symptom describing a problem. Based on these inputs, the EXALEAD Asset Quality Intelligence application searches for similarities, retrieves and organizes the information into dashboards for easy analysis of the similarities and refinement of the investigation criteria.

EXALEAD Asset Quality Intelligence application is using unsupervised machine learning techniques with patented algorithms that contribute to reducing the Investigation process, especially on massive amounts of data.

In the next blog installment, we will examine who is using Digital Twin technology and in which industries.

Part 1: What is a 3DEXPERIENCE Twin?

Part 2:DigitalTwins and Manufacturing: Today’s Possibilities

Part 3: Who is Using Digital Twin Technology?

Part 4: Growth Expectations for Digital Twins in Manufacturing

Part 5: Digital Twin Use Cases in Manufacturing

Part 6: Exploring Digital Twin Opportunities in Manufacturing

Part 7: Simulating Product Use with Digital Twins in Manufacturing

Part 8: Simulating the Manufacturing Process with Digital Twins

Part 9: Software in Digital Twin

Part 10: Real Data Versus Virtual Data

Part 11: Digital Twin: Pragmatic Considerations

Part 12: Recommendations for Getting Started with Digital Twin

Read our White Paper on Forging the Digital Twin in Discrete Manufacturing

Join our User Communities to stay on top of the latest industry news, ask questions and collaborate with peers:

- EXALEAD Sourcing & Standardization Intelligence User Community

- 3DEXPERIENCE Marketplace | PartSupply User Community

- NETVIBES Public Community

Learn more about EXALEAD on the 3DEXPERIENCE platform.