This is Part 5 of our 12-part blog series based on the LNS Research eBook,“Forging the Digital Twin in Discrete Manufacturing: A Vision for Unity In the Virtual and Real Worlds”.

Previously in Part 4 we investigated growth expectations for Digital Twin technology. Now let’s look at some manufacturing use cases for Digital Twins.

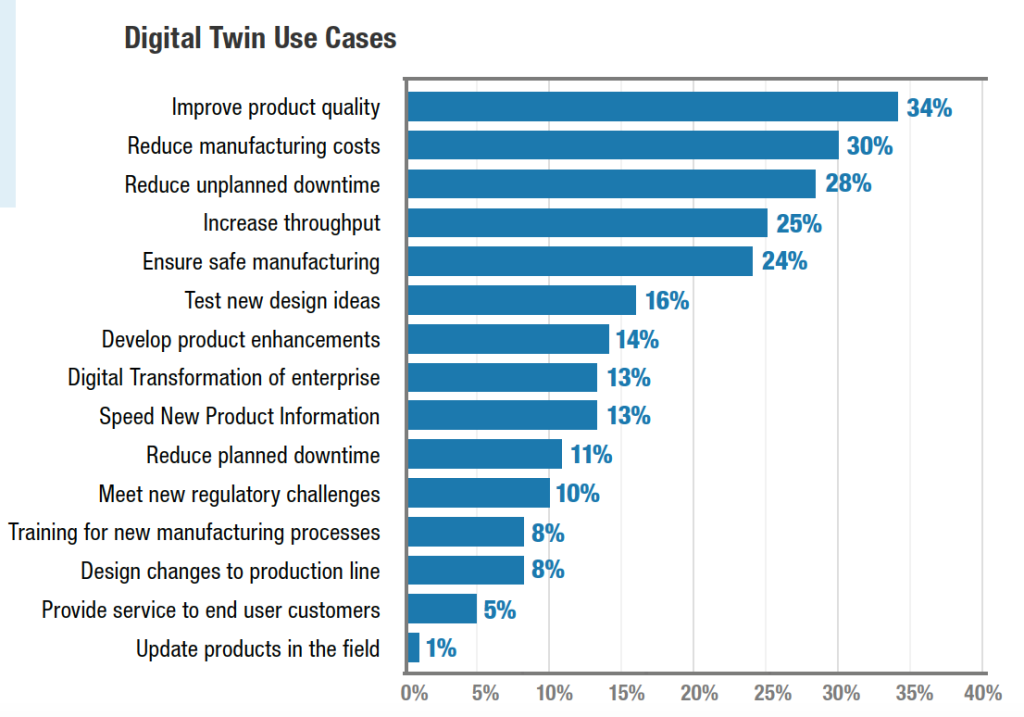

Digital Twin Use Cases

The use cases listed below strongly focus on the manufacturing process rather than the product. In these early stages, this is what LNS expected to find in its research. At the bottom of the use case spectrum we find activities like “update products in the field,” and “provide service to end-user customer.” These are the activities that are much more likely among mature Digital Twin users.

Finally, as we examine the manufacturing business processes covered by twins, we find that 3D design and manufacturing operations head the list, closely followed by many different forms of simulation including environment, manufacturing process, machine and of course product simulation.

Digital Twin Still “New” But Not Untried

Since the use of Digital Twin is still somewhat new, and this is the first LNS Research survey dedicated solely to the topic, we can’t look back to see how the use of the technology has evolved. That doesn’t limit our ability to clearly understand where the market is today and what’s on the horizon. Overall, we are pleasantly surprised by the results, particularly where discrete manufacturing is concerned. We find broad implementation of the technology across industries, with the more complex manufacturing segments being the leaders. Single plant digital twin systems are becoming widespread. We would certainly expect to see more sophisticated twins in the coming few years, as more companies get access to complex simulation systems and collect data from broader sources.

EXALEAD Commentary

As LNS Research has found, improving quality is the major driver in the value chain. Companies are seeking more actionable insights from their data in order to improve product quality and the customer experience at each step, from conception to design to manufacturing to delivery.

Although CRM (Customer Relationship Management) solutions helped during the last decade to focus on the consumer, the isolated claims reported by users were not really impacting the business. However today, with the power of social networks, the situation has changed. An unsatisfied customer can now have a severe impact on a brand image, making it critical for manufacturers to respond with agility to market demands.

On the 3DEXPERIENCE platform, EXALEAD Big Data analytics combined with machine learning techniques will assist OEMs in monitoring the behavior of the installed base, detecting patterns and enabling proactive intervention to prevent failures.

Dassault Systèmes’ Asset Quality Intelligence solution is providing a close feedback loop into the design and the engineering processes where issues can be analyzed in the context of the 3DEXPERIENCE twin. Knowing the exact configuration of the installed base of the assets allows services organizations in charge of maintenance and repair activities to be more efficient—by anticipating problems, providing necessary tools, bringing the correct spare parts—and do it right the first time

In the next blog installment, we will explore Digital Twin opportunities in manufacturing.

Part 1: What is a 3DEXPERIENCE Twin?

Part 2: Digital Twins and Manufacturing: Today’s Possibilities

Part 3: Who is Using Digital Twin Technology?

Part 4: Growth Expectations for Digital Twins in Manufacturing

Part 5: Digital Twin Use Cases in Manufacturing

Part 6: Exploring Digital Twin Opportunities in Manufacturing

Part 7: Simulating Product Use with Digital Twins in Manufacturing

Part 8: Simulating the Manufacturing Process with Digital Twins

Part 9: Software in Digital Twin

Part 10: Real Data Versus Virtual Data

Part 11: Digital Twin: Pragmatic Considerations

Part 12: Recommendations for Getting Started with Digital Twin

Read our White Paper on Forging the Digital Twin in Discrete Manufacturing

Join our User Communities to stay on top of the latest industry news, ask questions and collaborate with peers:

- EXALEAD Sourcing & Standardization Intelligence User Community

- 3DEXPERIENCE Marketplace | PartSupply User Community

- NETVIBES Public Community

Learn more about EXALEAD on the 3DEXPERIENCE platform.