This is Part Three in a series on Strategic Mine Planning. Part One focused on Putting the Strategy Back into Strategic Mine Planning. Part Two discussed Taking the Pain out of Tactical Planning.

A good quality mine planning process includes both strategic and tactical components. When a flawed planning process is employed, issues often manifest in the short term or short-term production planning & scheduling software areas. A three phased mine planning process can be employed to avoid this tactical planning pain in an open cut mine.

The three phases of mine planning ensure that the highest value is received from an open cut mine based on a practical schedule, which is implemented in a shorter planning horizon.

Phase 1: Practical NPV Schedules

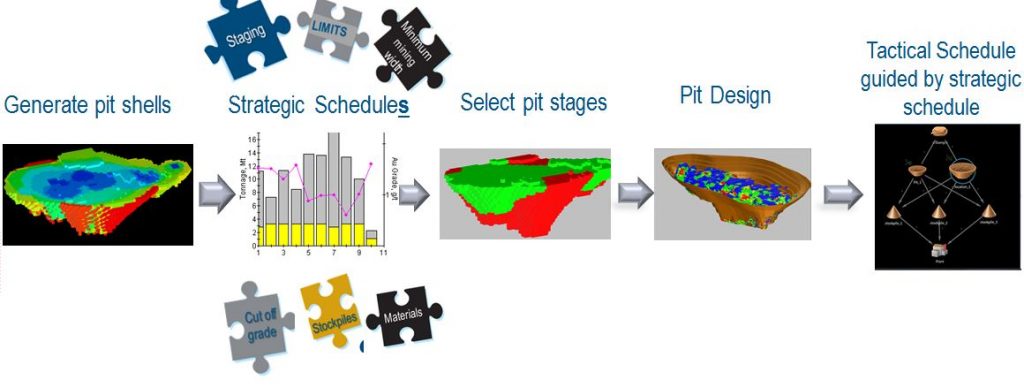

The first phase results in practical NPV-based schedules. The schedules include pit stage selection (chosen from a series of nested pit shell candidates and not based on the sub-optimal criteria of revenue factor 1!), determination of an NPV driven mining sequence and application of mining practicalities. Best practice pit shell generation requires careful preparation of input parameters, including activity based costing and application of the theory of constraints.

Once pit shell candidates are created in a Lerch Grossman algorithm, the truly strategic planning begins with scenario analysis of multiple schedules representing different strategies. The pit shells for the interim stages have a greater impact on NPV than the stages in later years of the mine life; therefore, optimum interim pit shell selection is vital for strategic planning success. Interim pit shells are not an input to the schedule, but rather an output of an automated scheduler which has all of the pit shell candidates to choose from.

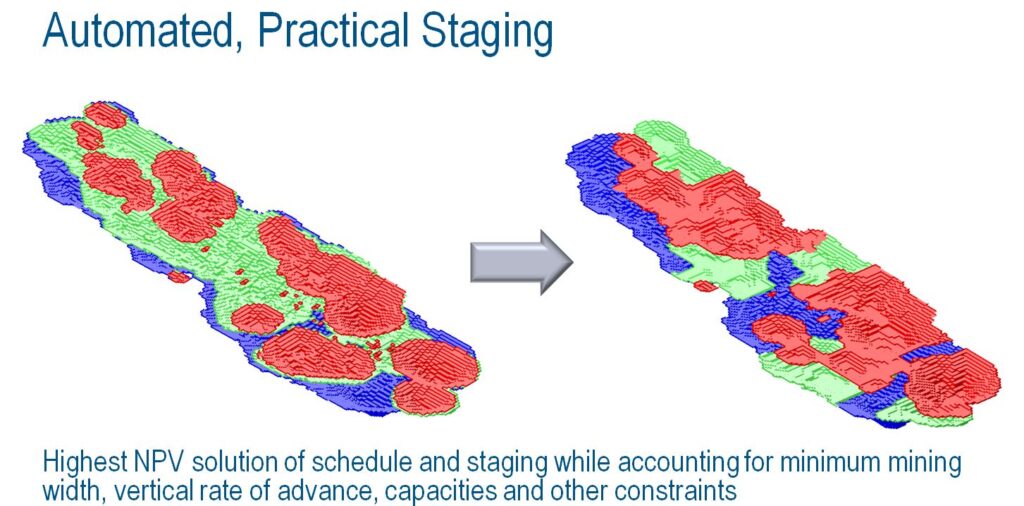

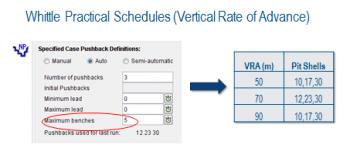

The pit shells also need to be modified for minimum mining dimensions while minimizing the reduction in NPV. GEOVIA Whittle’s NPVP module automatically finds the pit shells for the interim stages with the highest NPV after modifications are made for mining equipment practicalities. It also finds the mining sequence that generates the highest NPV for the modified shells, while honoring constraints such as fleet and process plant capacities, vertical rate of advance and input parameters changing with time.

The above image refers to the output from Whittle’s NPVP module showing that different pit shells are chosen for different annual vertical rate of advance limits.

The pit shell for the final stage is chosen using the skin analysis methodology in the NPVP module. Other key learnings from phase 1 include project sensitivities and robust areas of the pit.

Phase 2: Simultaneous Optimization

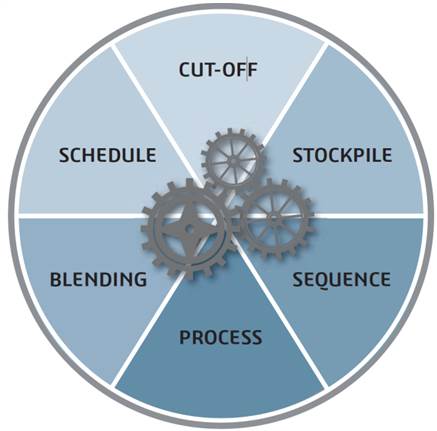

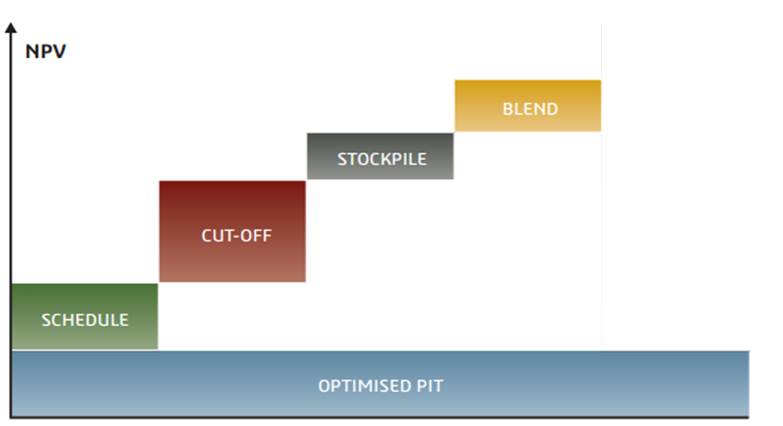

To truly receive the most value from a project, simultaneous optimization of mining sequence, cut-off grade, stockpiles and blending is performed. Whittle’s SIMO module performs the optimization of all items in one step, producing a higher NPV solution than a sequential optimization of the same parameters.

To truly receive the most value from a project, simultaneous optimization of mining sequence, cut-off grade, stockpiles and blending is performed. Whittle’s SIMO module performs the optimization of all items in one step, producing a higher NPV solution than a sequential optimization of the same parameters.

A variable cut-off grade strategy (as opposed to a static marginal cut-off grade) allows the highest value material to be processed soonest in the mine life. Cut-off grade optimization is aided by strategic stockpiling capacity so that medium value material can be set aside for later processing, allowing more high value material to be processed earlier.

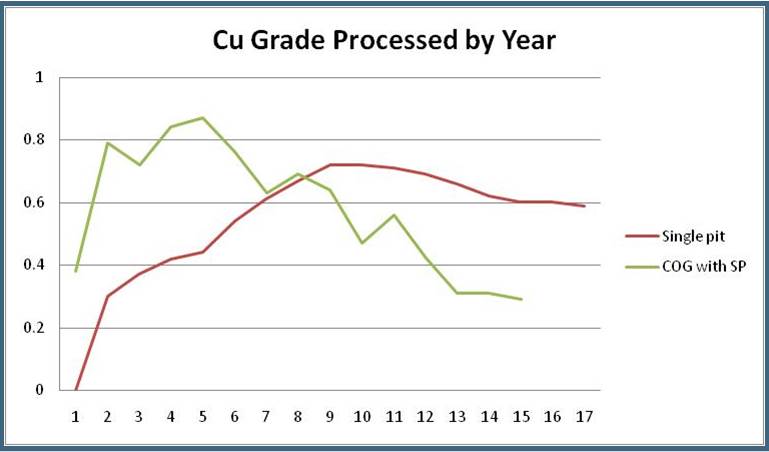

Below, the graph illustrates the comparison of annual processed grade using a traditional static cut-off grade (in red) versus optimized cut-off grade (in green) from Whittle’s SIMO module.

Again, this phase includes strategic investigation of schedule items such as number of stockpiles, stockpile definition, blending definition and the previously-listed schedule constraints. An important final step in the strategic workflow is exporting the chosen pit shells, creating pit designs and importing the pit designs back into Whittle. This allows the schedule to run on the pit designs rather than the pit shells, and provide final output for Phase 3.

Phases 1 and 2 detail a strategic workflow in Whittle, which can be compared to a tactical workflow.

Strategic Workflow:

Tactical Workflow:

Phase 3: Tactical Implementation

All the hard work of the first two phases is wasted, if the strategic plan is not used as the basis for the tactical plans to follow. Implementing the Whittle schedule and outputs in a tactical scheduler such as GEOVIA MineSchedTM is vital for the translation of the company mission and strategy to mining production.