Drafting is an important technique used in motor vehicle racing as well as cycling. Truck platooning works on the same principle, with two or more trucks traveling in a tight convoy to reduce aerodynamic drag and save fuel. It’s like extreme tailgating — reflexes to acceleration, sudden braking, lane changing and other movements by the lead truck at the head of the platoon are quickly emulated by the other trucks following behind. To achieve this, vehicles are tethered wirelessly so that they can communicate with one another quickly and constantly.

Truck platooning optimizes transportation by using roads more effectively, reducing traffic congestion and delivering goods faster. It has been in the ‘testing’ stage for years. You can refer to a number of studies and extensive literature review on the subject as well as its benefits and regulatory challenges.

To Platoon or Not to Platoon?

Scientists from the Massachusetts Institute of Technology (MIT) discovered that platooning saves fuel by up to 20% for vehicles in the middle and 15% for the one farthest to the back. But, there are many aspects to consider in deciding whether to have trucks travel in a platoon or directly to the destination instead. Factors include fuel consumption, delivery windows and the individual truck’s speed profiles. Many researchers attempting to model the problem face great difficulty coming up with an optimal plan.

For example, platooning that requires a long detour for a truck to travel from the distribution center (DC) to join a platoon would incur additional fuel cost, and this could negate the savings gained by platooning. This is easy to figure out for five or 10 trucks. But what about a fleet of 50 or 500?

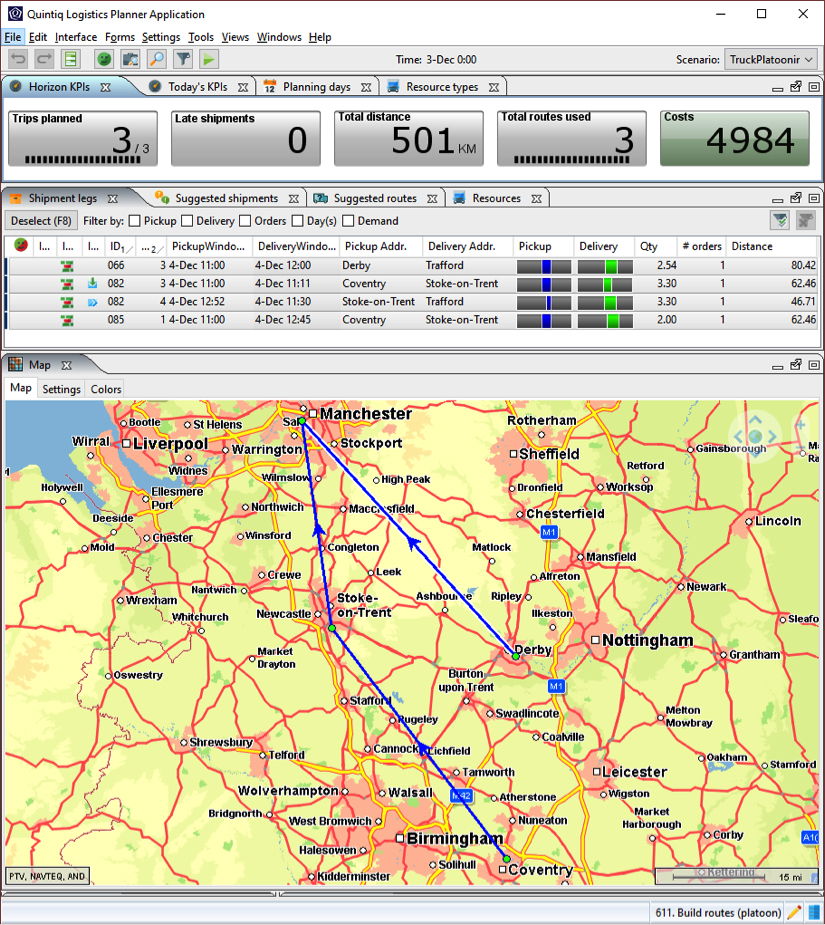

The planning of shipments and routes to form an optimal combination of trips from the DC to the meeting point for platooning is where DELMIA Quintiq’s core planning capabilities are well-poised to solve. DELMIA Quintiq’s optimizer takes into account the factors mentioned above, which is reflected in its cost function and delivers a plan that minimizes cost. Important KPIs such as on-time performance are presented to the planner, who will be able to gauge the plan’s worthiness.

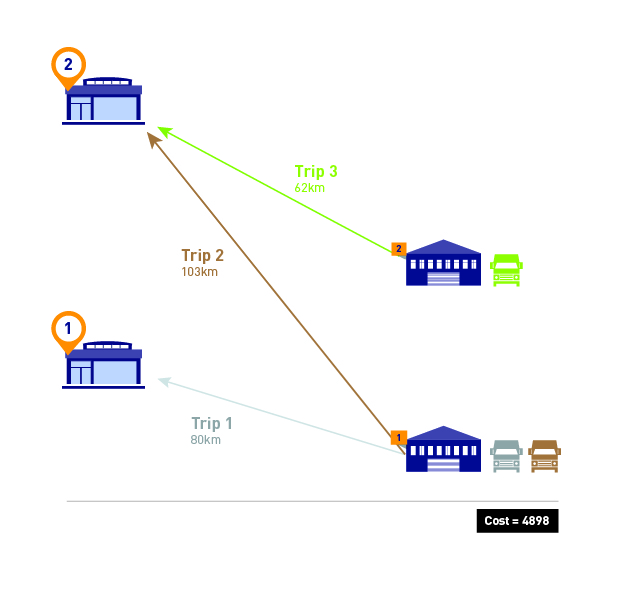

In a typical plan there could be as many as 100 trips. But as an example let’s focus on three:

- Trip 1 from Depot 1 (Coventry) to a customer at Stoke-on-Trent

- Trip 2 from Depot 1 (Coventry) to a customer at Trafford

- Trip 3 from Depot 2 (Derby) to a customer at Trafford

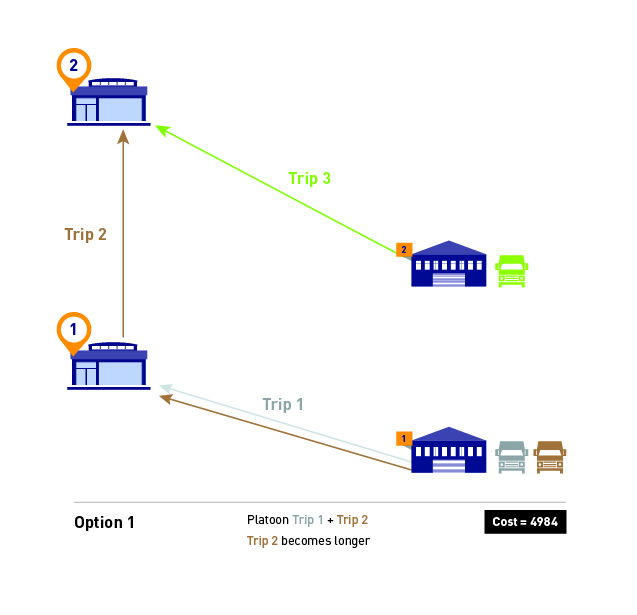

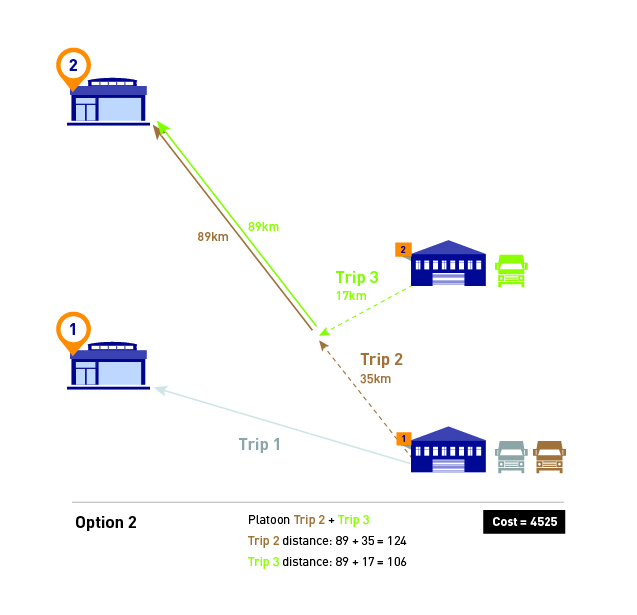

We can consider two possible options here, with the cost reflecting the overall benefit of platooning (where a lower cost is better):

DELMIA Quintiq helps planners determine opportunities for platooning by visualizing what those opportunities would look like.

Platooning Trips 2 and 3 incurs additional traveled distance as the leading and following vehicles need to congregate at a start location as they do not originate from the same DC. As the optimizer accounts for fuel savings, the planner is able to switch between the platooned and non-platooned options and to see what that looks like.

DELMIA Quintiq automatically calculates KPIs to measure how good the plan is, but the planner remains in control and has the final decision to either go with the plan given by the optimizer or tweak it.

How Close are We to Putting Platoons on the Road?

Volvo Trucks North America is currently testing truck platooning with FedEx and the North Carolina Turnpike Authority. The platoon is made up of Volvo VNL tractors pulling double 28-foot trailers at speeds of up to 100km per hour while keeping a time gap of 1.5 seconds.

To learn how platooning can improve fleet efficiency, Volvo VNL tractors are paired with various combinations of FedEx trailers to simulate real-world routes and trailer loads. Braking is automatic and immediate, with the lead vehicle taking just one-fifth of the time a person would need to react.

Despite platooning’s many benefits, the sight of platoons on the highway is nowhere on the horizon. Apart from Volvo, we’ve seen announcements from Hino Motors as well as Daimler but there needs to be more participants entering the space to incentivize them to improve communication protocols between different truck brands.

Truck platooning requires new laws and regulations before they can hit the roads commercially. The good news is that 17 U.S. states have already declared that platooning is allowed within their borders. The next step would be to legislate interstate platooning, and the sooner the better as I can’t wait for the day when truck platooning becomes a reality.

I hope I’ve given you a preview of how DELMIA Quintiq’s capabilities can be used to solve the planning puzzle inherent in platooning and deliver fuel efficiency through route optimization. Find out more about the optimization technology that gives our solution — and your operations — the competitive edge in this guide.