Effective and Efficient Supply Chains

Companies that manage their supply chains in an effective and efficient manner will find themselves ahead of the competition. An effective supply chain delivers the right product to the customer at the right moment in time, whereas an efficient supply chain does this against the lowest costs possible. Since the 1990s, software to support supply chain management decisions has become more popular. Initially coined as Finite Capacity Planning (FCP) systems, these have evolved from Advanced Planning & Scheduling (APS) software to Supply Chain Planning & Optimization (SCPO). However, this type of software is typically more complex to understand––and hence to implement––than Enterprise Resource Planning (ERP). Vendors of Supply Chain Planning & Optimization software have set high expectations of possible benefits, yet many customers that have started implementation projects struggle to achieve them. This blog highlights the challenges of supply chain management, the four most important traits that an organization should have prior to applying Supply Chain Planning & Optimization solutions, and the critical role of continuous improvement in this process.

The Complexity of Supply Chain Management

A supply chain consists of a set of interconnected resources that delivers products to customers. Examples of supply chains can be found everywhere: an aircraft producer; a trans-shipment company that moves containers; a company that produces specialty chemicals for other companies to be further processed; an airport that deals with incoming and departing flights; a factory that produces steel that is again used by other companies to produce cars, packaging materials, and the like. Typically, supply chains are built up by humans or machines, connected by means of transport, and warehouses where intermediate and finished products are stored.

The complexity of a supply chain can be described across many dimensions. The number of elements, and the relationships between the elements, obviously is a measure for a supply chain’s complexity. A product that only needs two steps to be produced is most likely easier to manage than products that need hundreds or even thousands of operations, divided over multiple sites, where every site has a multitude of resources that carry out part of the work. A supply chain delivering thousands of products is probably more complex than one producing five products – although other factors can play a more dominant role. Lastly, the complexity of supply chains is determined by the way customers order products, and the reliability of its suppliers. For example, demand that is very unpredictable is more complex to manage than stationary demand, which is (almost) stable from period to period.

Supply Chain Management: A Human Task Supported by Systems

Supply chains are usually managed by departments that focus on the planning and execution of the supply chain operations. As supply chains are complex, there is a large number of tasks that need to be carried out as part of supply chain management. These can be high-level, strategic business planning decisions, such as, where to build a new warehouse. At the same time, supply chain management is about making detailed decisions about short-term events, such as, when a particular truck should leave the dock and what should be loaded into it.

An important part of supply chain management is making decisions about future events, i.e., planning. The complexity of supply chain planning is the direct result of the complexity of the supply chain itself. And much of the decision-making in supply chain management is still done by human professionals, notwithstanding the increasing adoption of ERP and SCPO systems. Although humans have important strengths compared to computers, they also struggle dealing with the complex planning puzzles they need to solve. This is where supply chain planning should enable the human decision makers to capitalize on their strengths and mitigate their weaknesses.

1. Vision

Know what you want and know how to get it. This is the first key success factor when considering to implement Supply Chain Planning & Optimization systems. To illustrate this point, it is useful to explain the less preferred approach: not really understanding Supply Chain Planning & Optimization and how it can improve supply chain management. Whether trusting a vendor’s sales pitch or, approaching this from a pure financial point of view––requesting a team of consultants, or the supplier, to create a financial business case, and make a go/no go decision. However, financial business cases are always based on assumptions and best guesses, even though apparently intricate calculations, based on the input of these best guesses, could suggest otherwise.

Do the main stakeholders want the supply chain to become a success? And do they know how to achieve that? In that case, the vision is there and this will provide the right direction for the implementation project. Every company should make sure that future users of the system are consulted in defining that vision. For managers, it can be instructive to spend a couple of hours with the planners, so they can understand the complexities of planning and how a Supply Chain Planning & Optimization solution can support this.

2. Brains

The implementation of complex solutions such as Supply Chain Planning & Optimization can only be successful when there are enough resources within the company who understand how these systems work, how they can be customized, and how they should be embedded in the company’s system landscape. Companies should not make themselves entirely dependent on consultants or the supplier for such knowledge. Consultants, and the vendor, will leave the project at some point––when the system is delivered, or when the budget is consumed––so there should also be internal human resources that can manage the continuous improvement that should happen after the Supply Chain Planning & Optimization system goes live. Without this, the system might be technically live, but it might not bring any benefits.

3. Data

A key characteristic of Supply Chain Planning & Optimization systems is that they are data hungry. The planning task is fundamentally different from the type of tasks supported by manufacturing ERP software––the latter of which supports mainly analysis tasks, whereas planning is a synthesis task. In analysis tasks, predefined steps are taken to come to one particular outcome. In synthesis tasks, pieces of information are assembled into a plan, and there are multiple plans that can potentially be executed. In other words, a plan is an assembly of information.

Many companies struggle to get the right information that is required for Supply Chain Planning & Optimization. In particular, information about possible production routes, and execution feedback, can be incomplete and erroneous. But also, more fundamental questions may surface, such as, where do we decouple production and how much stock/Work-In-Process (WIP) do we allow where?

Although many vendors will flag upfront that data availability and quality are crucial, many companies will be surprised at the first version of the planning screen or Gantt chart when it shows an almost empty factory or a load situation which is completely different from reality. What follows is a potentially stressful period, where data analysts work overtime to gather the bits and pieces and put them together.

4. Predictability

As planning is about making statements about the future, the future must be predictable to some extent. When this is not the case, it does not make sense to plan, and SCPO will not add any value. There is a large grey area here, which means that uncertainty should not be too high, and some judgement is needed to determine what level of uncertainty is acceptable. SCPO systems can still add value in situations with uncertainty, by allowing quick revisions of the plan and to show the consequences of changes made.

Care should be taken when applying optimization techniques to situations that need much replanning as a result of uncertainty. For example, a factory producing chemicals wanted to automatically generate a schedule that did not need any human intervention. The scheduling horizon was three days, however, the level of uncertainty in the factory was such that the schedule had to be recreated every three hours. Obviously, the ‘optimal’ schedule was never achieved, as it was changed all the time.

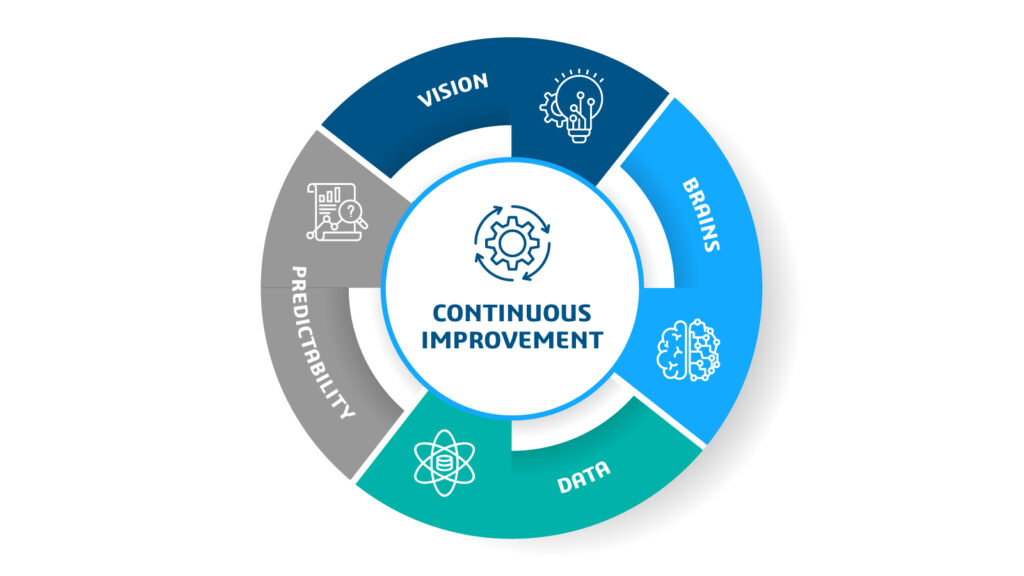

The Most Challenging Project Phase: Continuous Improvement

The process of reaping the benefits of any supply chain planning system will be after the go live of the software. In many cases, the go-live event is almost a technical one – the system gets data from live sources and it sends information that can actually be used for planning. Typically, the project team that was responsible for implementing the supply chain is sent off to other projects after the go live, to leave the aftercare to the users, who might be less skilled in realizing improvements. The people who use the system on a daily basis might struggle to integrate the system into their professional lives. They are not thinking about return on investment, delivery performance, and inventory costs anymore. They have to deal with the newly installed support organization, training other users, and getting the right data out of the system to keep the business processes working. Without a continuous improvement process in place, the benefits that were once projected will probably not materialize.

A Supply Chain Planning & Optimization system can be compared to a subscription to an (expensive) fitness club. Having the subscription alone will not help you achieve your desired results––that comes with training. And to do so intelligently, you need to analyze your body’s needs, your personal preferences, and based on that, select the training scheme that will help you achieve your objectives. The same goes for Supply Chain Planning & Optimization: with these systems in place, planners will be able to use powerful tools to create the same plans as before, but better. They can increase the delivery reliability, shorten lead times, increase resource usage, lower the costs of purchased materials, and more. To do that, they will need to measure the plan performance and find out the correct strategies to improve it. This is a continuous process of measuring, improving, and analyzing the results, making changes and going through the same cycle again. Having a vision, the right brains on board, correct and complete data, and predictability in the process being planned will make this possible. Continuous improvement never stops!